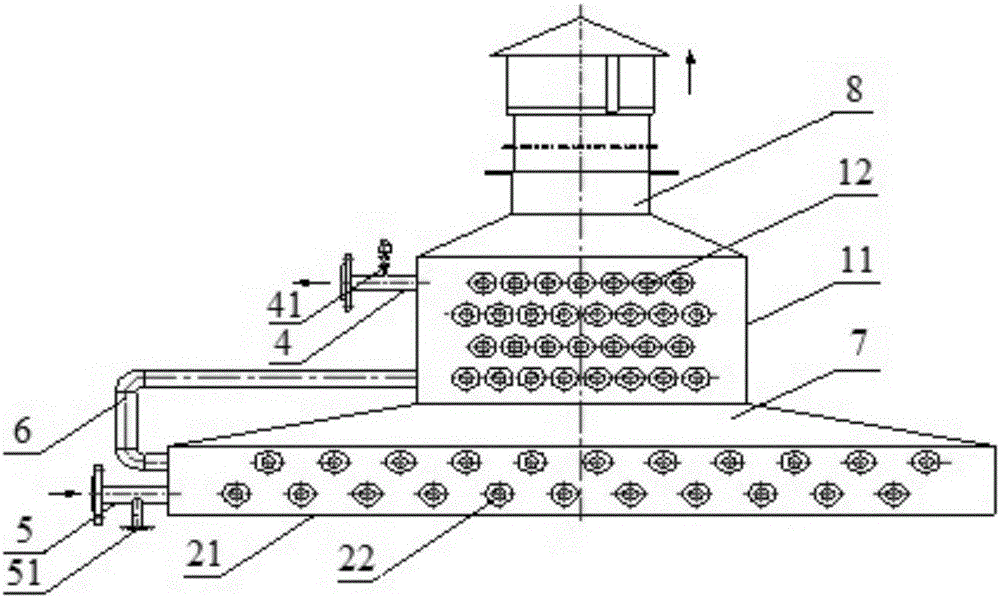

Mesh belt continuous heating carburizing furnace door cover flame waste heat recovery and reuse device

A waste heat recovery and carbon furnace technology, applied in lighting and heating equipment, furnaces, waste heat treatment, etc., can solve problems such as energy waste and fire, and achieve the effects of reducing production costs, reducing possibilities, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

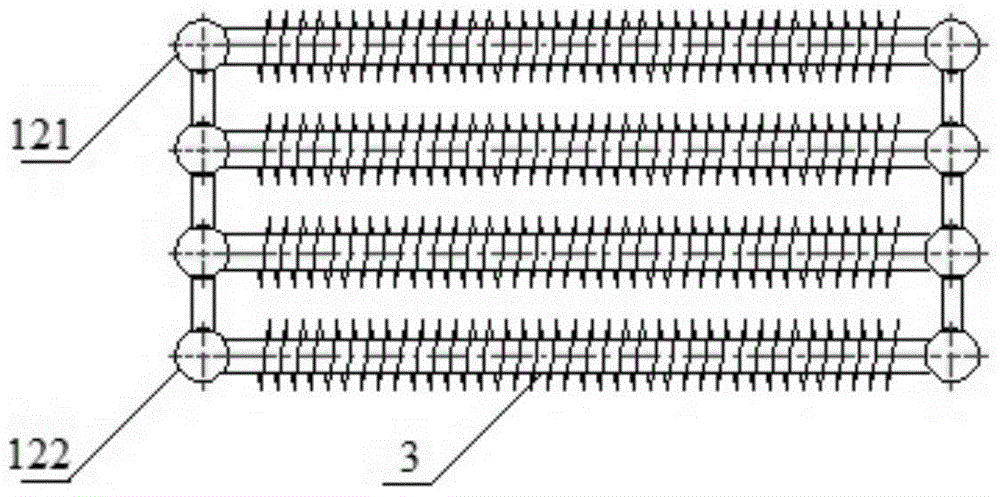

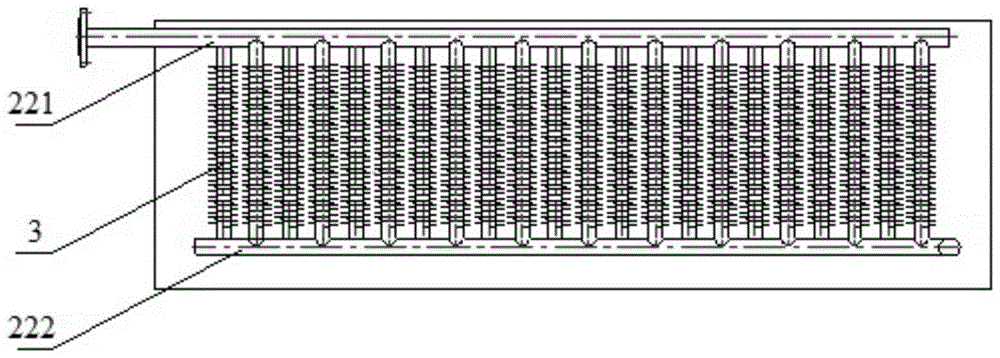

Examples

preparation example Construction

[0084] In a preferred embodiment according to the present invention, a thermal insulation layer is coated on the inner wall of the upper cover body 11, the square pipe 7, and the lower cover body 21, and the thermal insulation layer is used to suppress heat passing through the wall of the carburizing furnace. The coating that is transmitted outward, the heat insulation layer is coated with high-temperature radiation coating, and the thickness is 0.2-0.5mm. The preparation method includes: uniformly coating the high-temperature radiation coating on the On the inner wall of the upper cover body 11, the square pipe 7 and the lower cover body 21, dry at 20-40°C for 12-48 hours to obtain the heat insulation layer;

[0085] The preparation method of the high-temperature radiation coating includes: powdery zirconia (ZrO2) with a particle size of 70-150 μm 2 ), ferric oxide (Fe 2 o 3 ), chromium trioxide (Cr 2 o 3 ), silicon dioxide (SiO 2 ) is mixed according to the weight ratio...

Embodiment 1

[0103] The preparation of embodiment 1 high temperature radiation coating

[0104] Powdered zirconia (ZrO2) with a particle size of 100-120 μm 2 ), ferric oxide (Fe 2 o 3 ), chromium trioxide (Cr 2 o 3 ), silicon dioxide (SiO 2 ) mixed according to the weight ratio of 2:2:3:1, adding 12% silica sol of the total mass of the above powder, mixing evenly, and calcining at 1300° C. for 10 hours; cooling down to room temperature, and processing in a ball mill for 25 minutes to obtain a particle size of Particles of 40-60 μm; mix the above particles with sodium carboxymethyl cellulose and polyacrylic acid evenly, and disperse them by ultrasonic waves for 40 minutes to obtain a viscous slurry which is the high-temperature radiation coating.

Embodiment 2

[0105] Embodiment 2 The preparation of thermal insulation layer

[0106] The high-temperature radiation coating prepared according to the method described in Example 1 is evenly coated on the inner walls of the upper cover body 11, the square and round pipes 7 and the lower cover body 21 by spraying, and dried at 25°C for 48 hours to obtain the heat insulation coating. Insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com