Oil base drilling fluid parameter design method

An oil-based drilling fluid and a design method technology, applied in the field of oil and gas drilling engineering, can solve the problems of high drilling fluid performance and increased cost, and achieve the effects of controlling costs, preventing complex situations in the well, and avoiding excessive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

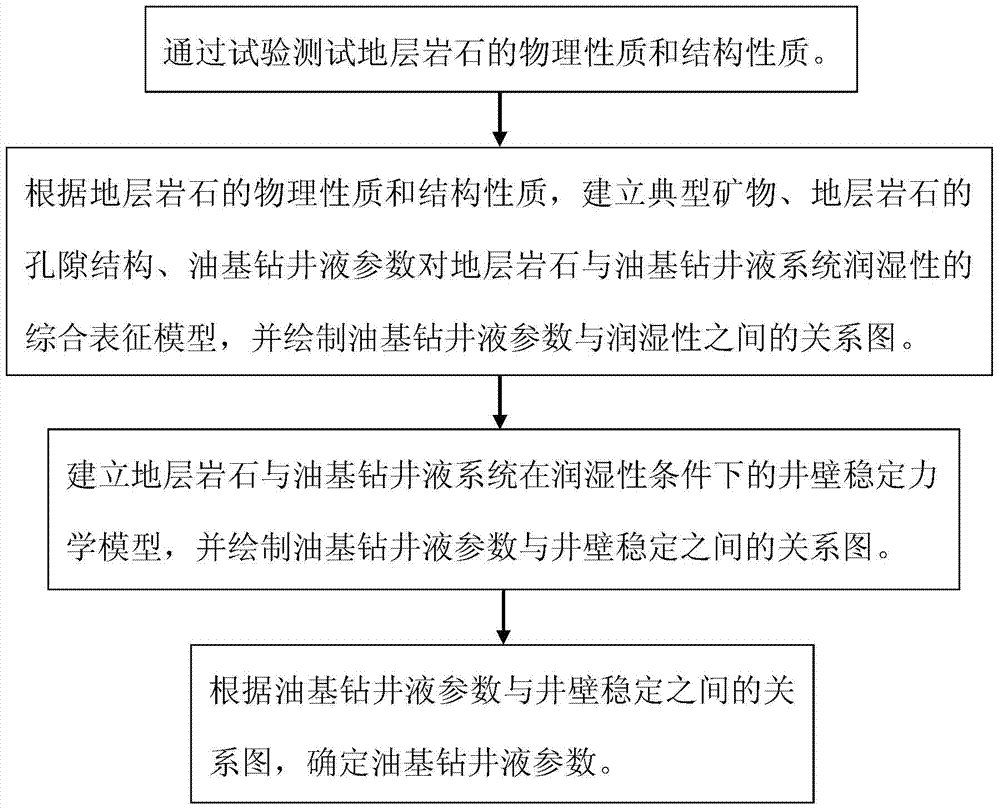

[0088] Such as figure 1 As shown, in this embodiment, a shale formation in a block in Sichuan, China is selected, and the key parameter window of oil-based drilling fluid is designed based on the wetting theory of the formation rock and oil-based drilling fluid system. A method for designing oil-based drilling fluid parameters, which comprises the following steps in sequence:

[0089] Step 1: Test the physical and structural properties of formation rocks through experiments.

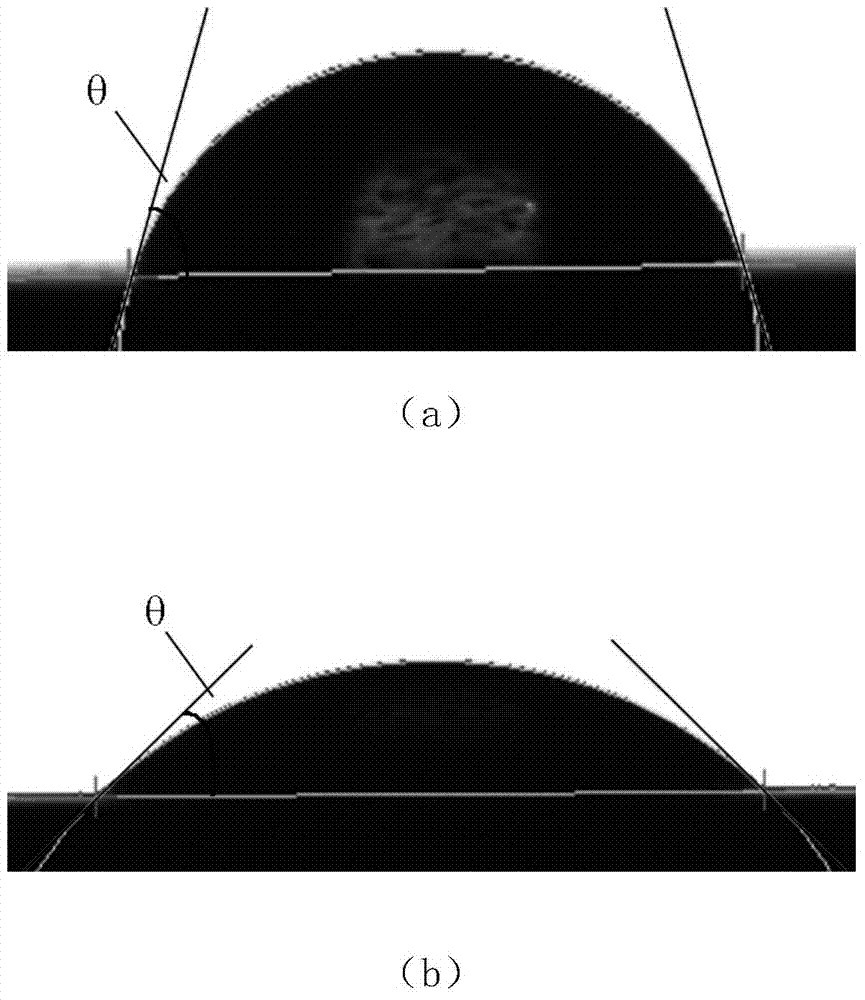

[0090] Ten shale formation samples were taken to test their physical and structural properties. X-ray diffraction test is used to test the mineral composition of formation rocks; pyrolysis test and vitrinite reflectance test are used to test the total organic carbon content (TOC), kerogen type, maturity of formation rocks; with the help of scanning electron microscope (SEM) and transmission electron microscope (TEM) to qualitatively observe the two-dimensional pore distribution characteristics in forma...

Embodiment 2

[0147] In this example, the mudstone formation in a block in Karamay, Xinjiang is selected, and the key parameter window of oil-based drilling fluid is designed based on the wetting theory of formation rock and oil-based drilling fluid system. The design method is the same as that of Example 1.

[0148] the difference is:

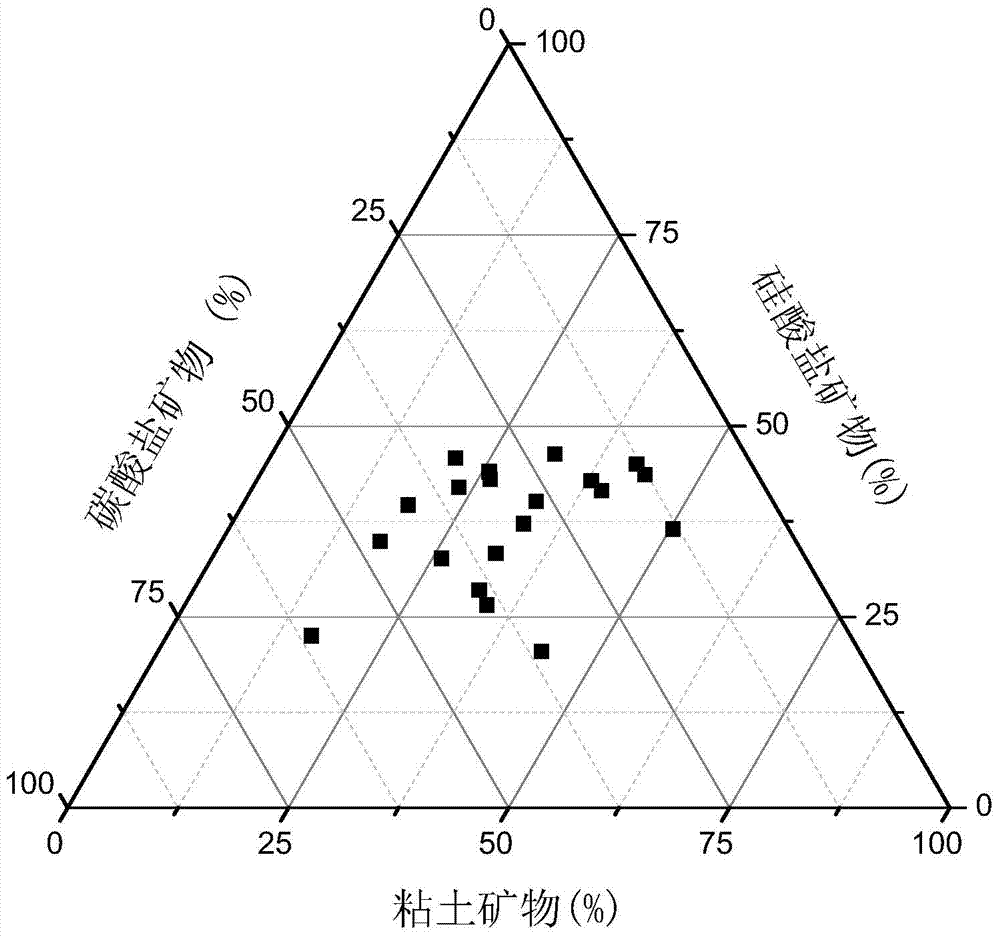

[0149] Twenty mudstone formation samples were taken, and their physical properties and structural properties were tested respectively. After excluding samples with large errors from the twenty formation rock samples measured, the remaining samples were used for subsequent design. In this embodiment, the data of three typical samples are selected from the remaining samples as an example. The mineral composition, total organic carbon content, kerogen type, and vitrinite reflectance test results of the three formation rock samples are shown in Table 2.1. The porosity and fracture toughness test results of the three formation rock samples are shown in Table 2.2...

Embodiment 3

[0163] In this embodiment, a sandstone formation in a block in Yunnan, China is selected, and the key parameter window of oil-based drilling fluid is designed based on the wetting theory of formation rock and oil-based drilling fluid system. The design method is the same as that of Example 1, except that:

[0164] Twenty-five sandstone formation samples were taken, and their physical properties and structural properties were tested respectively. After excluding samples with large errors from the twenty-five formation rock samples measured, the remaining samples were used for subsequent design. In this embodiment, the data of three typical samples are selected from the remaining samples as an example. The mineral composition, total organic carbon content, kerogen type, and vitrinite reflectance test results of the three formation rock samples are shown in Table 3.1. The porosity and fracture toughness test results of the three formation rock samples are shown in Table 3.2.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com