A test method for analyzing metal contamination in silicon wafer body

A technology of metal contamination and testing methods, which is applied in semiconductor/solid-state device testing/measurement, material analysis by measuring secondary emissions, optical testing of defects/defects, etc. It can solve the problem of increasing the number of defects, affecting device performance, and channel Incomplete etching and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The testing process of metal contamination on the surface of the silicon wafer in this embodiment is:

[0024] 1. Silicon wafer selection: Collect the silicon wafers with excessive body iron in the SPV-Fe test and special pattern distribution, and save the SPV-Fe test results of each wafer.

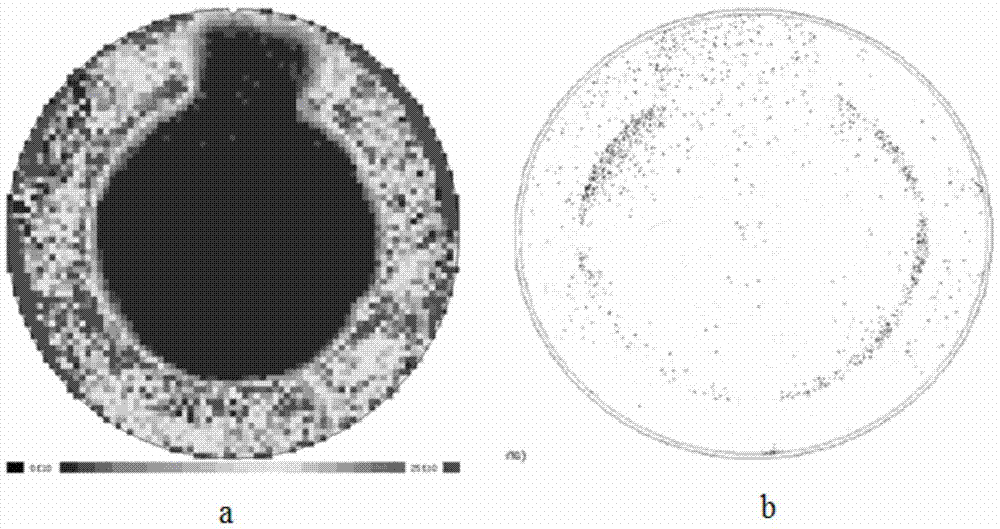

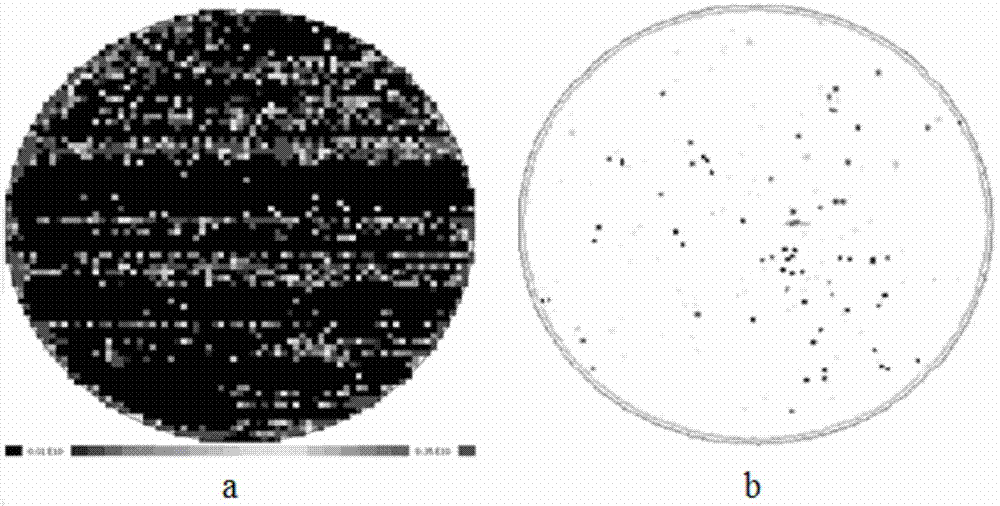

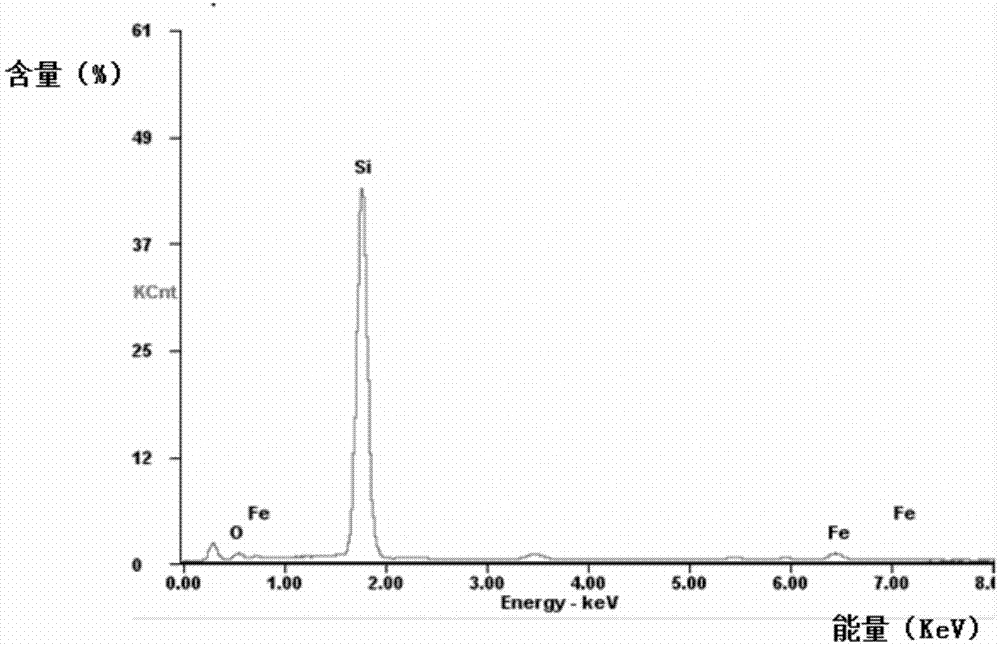

[0025] 2. Wafer cleaning: the silicon wafers with Fe contamination are cleaned in a silicon wafer cleaning machine. The cleaning process is completed in accordance with the standard cleaning procedure: SC-1 cleaning + pure water cleaning + HF cleaning + pure water cleaning + SC- 1 Cleaning + pure water cleaning + SC-2 cleaning + pure water cleaning + drying. After cleaning, use the surface particle tester SP1 to measure the surface particle distribution, and use ICP-MS to analyze the surface metal contamination distribution. After testing, it was found that the amount of surface particle contamination and the amount of metal contamination were both within a controllable range. See Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com