Pixel defining layer of light emitting display and manufacturing method thereof

A pixel-defining layer, light-emitting display technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of short circuit of cathode and anode, reduction of light-emitting area, reduction of discontinuous light-emitting area of cathode, etc., which is beneficial to the process. , the effect of improving light and color efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

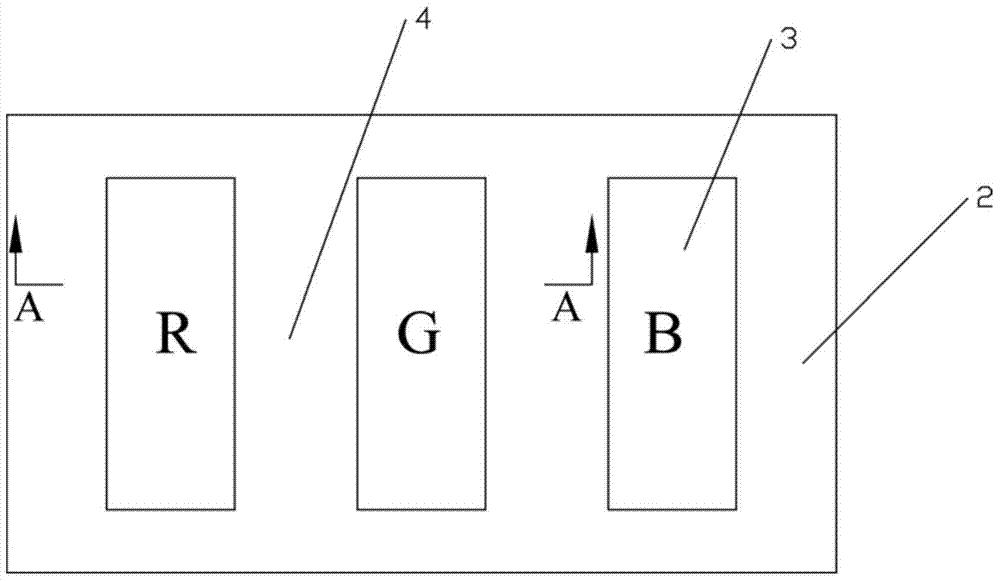

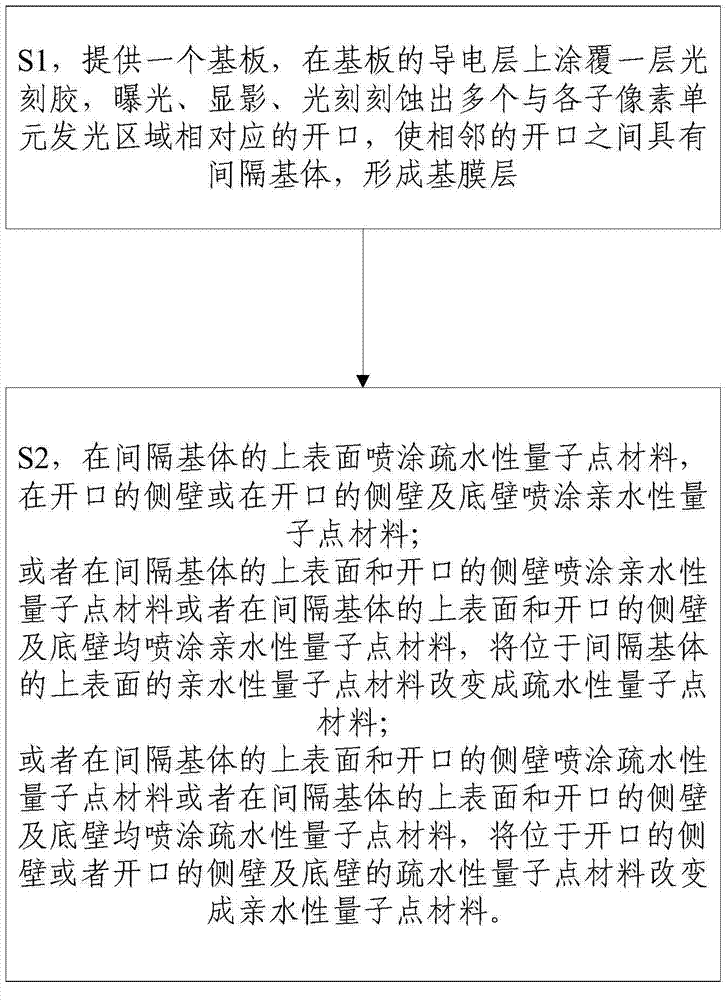

[0044] Embodiment 1 of the manufacturing method. This embodiment takes manufacturing a pixel definition layer of a pixel composed of three sub-pixels as an example. The specific steps are as follows:

[0045] like attached Figure 4 As shown, a substrate 1 is provided, and a layer of positive photoresist 11 is coated on the conductive layer of the substrate 1 . In this embodiment, the substrate 1 uses, but is not limited to, conductive glass, and the conductive glass is made of transparent glass above table The surface is formed by sputtering or ionic transfer to form a layer of transparent and conductive oxides. The oxides are indium tin oxide, aluminum zinc oxide, and indium zinc oxide.

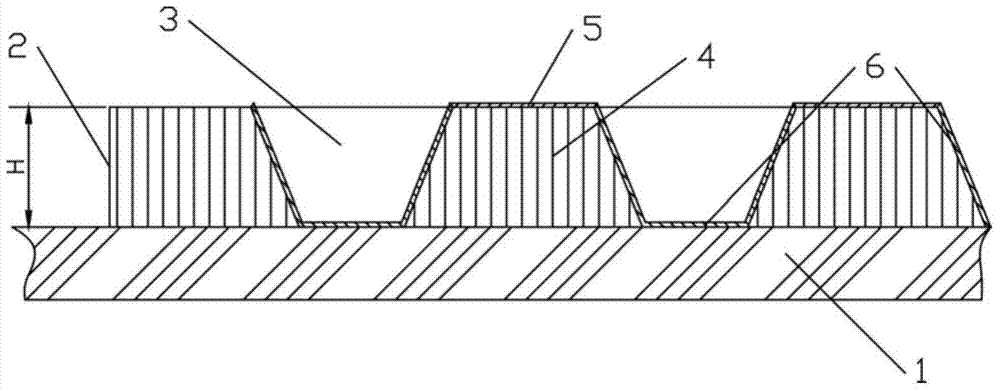

[0046] like Figure 5 As shown, after exposing and developing the positive photoresist 11, a plurality of openings 3 corresponding to the light-emitting regions of each sub-pixel unit are photoetched on the positive photoresist using a mask, so that adjacent A spacer matrix 4 is prov...

Embodiment approach 2

[0049] Embodiment 2 of the manufacturing method. This embodiment takes manufacturing a pixel definition layer of a pixel composed of three sub-pixels as an example. The specific steps are as follows:

[0050] like Figure 8 As shown, a substrate 1 is provided, and a layer of negative photoresist 12 is coated on the conductive layer of the substrate 1 .

[0051] like Figure 9 As shown, after exposing and developing the negative photoresist 12, a mask plate is used to photoetch a plurality of openings 3 corresponding to the light-emitting regions of each sub-pixel unit on the negative photoresist 12, so that the corresponding A spacer matrix 4 is provided between adjacent openings 3 to form a base film layer 2 . The longitudinal section of the spacer base 4 is an inverted trapezoid.

[0052] like figure 1 0, in spacer matrix 4 of the above table The surface and the side walls and bottom walls of the opening 3 are sprayed with hydrophobic quantum dot materials 5, and...

Embodiment approach 3

[0055] The difference between the third embodiment and the embodiment is that: in the spacer matrix above table The surface and the sidewall of the opening are sprayed with hydrophilic quantum dot material or in the spacer matrix above table The surface and the side wall and bottom wall of the opening are sprayed with hydrophilic quantum dot materials, and the quantum dots located in the spacer matrix are replaced by functional groups. above table The hydrophilic quantum dot material on the surface is changed into a hydrophobic quantum dot material.

[0056] It should be noted that the spraying of the present invention adopts the mode of nozzle spraying or electric arc spraying.

[0057] According to the pixel defining layer made by the above method for making the pixel defining layer, the pixel defining layer includes a base film layer, and the side walls of the opening of the base film layer or the side walls and bottom walls of the opening are coated with hydrophilic quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com