Instant spraying wetting compacting method for compression type Pu'er cooked tea

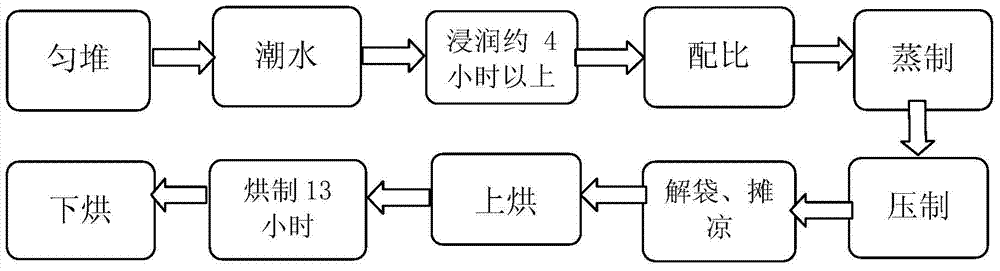

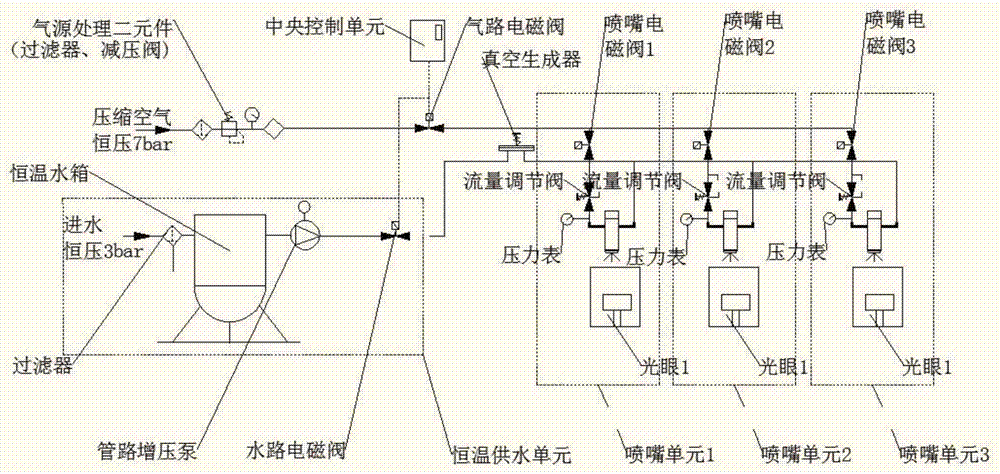

A technique of spraying tidal water for ripe Pu-erh tea, which is applied to the improvement of the tidal water process in the preparation process of pressed-type Pu-erh cooked tea. The technology field of "instant spraying and damp-pressing" of pressed-type Pu-erh cooked tea can solve the problem of food hygiene and safety. Low, prolonging the production cycle, long baking cycle, etc., to achieve food hygiene and safety, improve the consistency of moisture content, and improve the effect of food hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

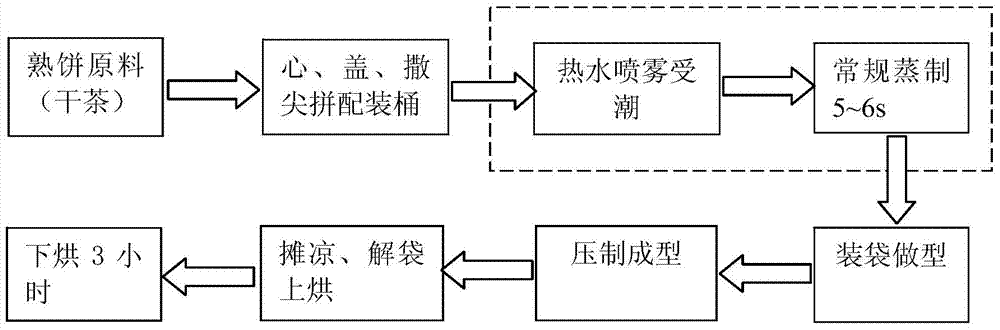

[0063] The instant spray damp pressing method of embodiment, compacted type Pu'er cooked tea

[0064] see figure 2 The shown process of instant spraying and pressing ("moisture and pressure") of compacted Pu'er cooked tea includes the following steps (the serial numbers listed are for the convenience of distinguishing steps, and do not necessarily represent the order of operation):

[0065] 1) Preparation of raw materials: Prepare the raw materials (or called tea leaves, dry tea, dry tea leaves) required for the preparation of pressed Pu-erh cooked tea. There are three different types of dry tea leaves for Pu’er cooked tea, which are divided into sprinkling tip, core tea and cover tea (cover tea is divided into fringe tea, face cover tea and sand bottom tea). The dry tea leaves can be selected according to needs. This embodiment only provides an example, and the process of the present invention is not affected by changes in the dry tea leaves.

[0066] 2) Assembling and bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com