Preparation method of graphene/ferriporphyrin/gold nanoparticle composite material

A composite material, iron porphyrin technology, applied in nanotechnology and other directions, can solve the problems of complex preparation process, unsuitable for mass production, use of toxic reagents, etc., and achieve the effects of simple preparation method, environmental protection and pollution-free preparation process, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

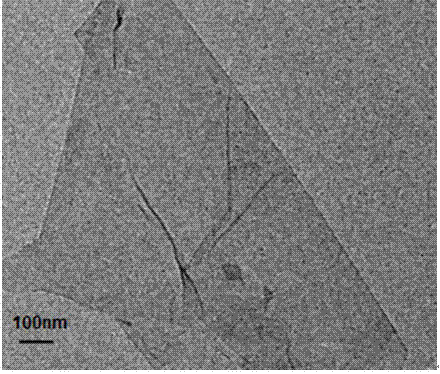

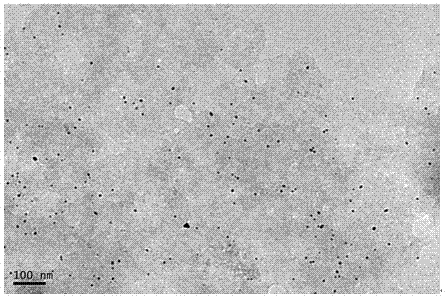

[0023] Utilize the hummers method Hummers WS, Offeman RE. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339-1339 to prepare graphene oxide, the transmission figure of the graphene oxide obtained is as follows figure 1 shown. First, 5 mL of graphene oxide aqueous solution (1.0 mg / mL) and 5 mL of iron porphyrin suspension (1.5 mg / mL) were sonicated at room temperature for 20 min, and the two were mixed and then sonicated for 10 min. Add 40 μL of 0.025mol / L HAuCl4 solution, mix by ultrasonication for 10min, add 0.5mol / L NaOH solution dropwise, adjust the pH value to about 10, and sonicate for 10min. The mixture was magnetically stirred in a water bath at 90°C, condensed and refluxed for 3 hours.

[0024] Centrifuge at 12000r / min to obtain the lower sediment; first wash off the residual iron porphyrin with tetrahydrofuran, then wash the lower sediment with deionized water, centrifuge and repeat several times until the pH of the supernatant is around 7 . The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com