Double-coating positive thermosensitive CTP plate

A double-coating, positive image technology, applied to photosensitive materials used in optomechanical equipment, printing plate preparation, printing, etc., can solve problems such as poor alkali resistance, soft hardness, and low printing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

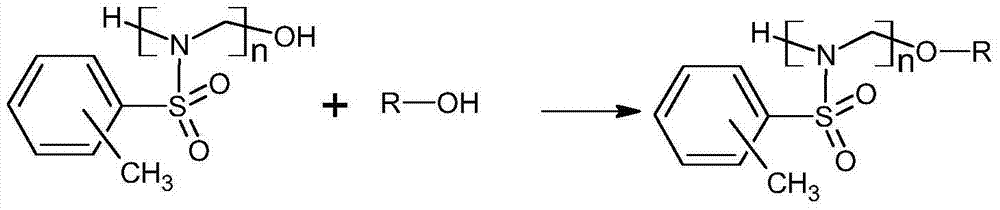

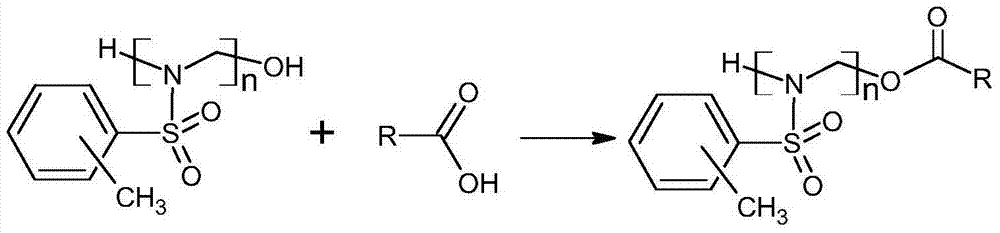

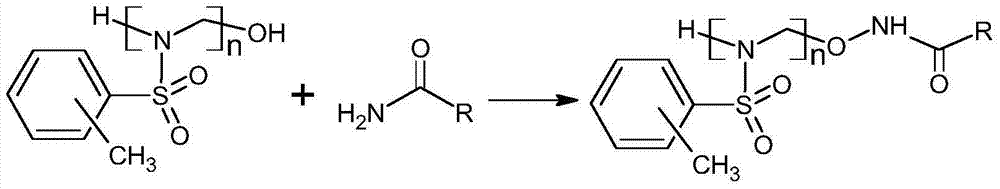

Method used

Image

Examples

Embodiment 1

[0131] Resin layer formula: 10 parts by weight of N,N-dimethylformamide (DMF), 10 parts by weight of butyl acetate, 65 parts by weight of ethyl cellosolve, UV-1 resin (Lucky Huaguang Printing Technology Co., Ltd.) 10 parts by weight, 4 parts by weight of o- or p-toluenesulfonamide formaldehyde resin (Nantong Wolan Chemical Co., Ltd.), 0.5 parts by weight of tetrahydrophthalic anhydride, and 0.5 parts by weight of methyl violet.

Embodiment 2

[0133] Resin layer formula: 10 parts by weight of N,N-dimethylformamide (DMF), 10 parts by weight of butyl acetate, 65 parts by weight of ethyl cellosolve UV-1 resin (Lucky Huaguang Printing Technology Co., Ltd.) 9 Parts by weight, o- or p-toluenesulfonamide formaldehyde resin (Nantong Wolan Chemical Co., Ltd.) 5 parts by weight, tetrahydrophthalic anhydride 0.5 parts by weight, methyl violet 0.5 parts by weight.

Embodiment 3

[0135] Resin layer formula: 10 parts by weight of N,N-dimethylformamide (DMF), 10 parts by weight of butyl acetate, 65 parts by weight of ethyl cellosolve, UV-1 resin (Lucky Huaguang Printing Technology Co., Ltd.) 7 parts by weight, 7 parts by weight of o- or p-toluenesulfonamide formaldehyde resin (Nantong Wolan Chemical Co., Ltd.), 0.5 parts by weight of tetrahydrophthalic anhydride, and 0.5 parts by weight of methyl violet. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com