Patents

Literature

97 results about "Para-toluenesulfonamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The estimated half-life of para-toluenesulfonamide equivalents in fingerlings was 27.3 hours whereas determined by HPLC the half-life of para-toluenesulfonamide residues in whole-body homogenates was 36.3 hours.

Production method of high solid content melamine resin

The present invention relates to a formula of high solid content melamine resin and its preparation method. Said melamine resin is made up by using melamine, liquid formaldehyde (industrial product concentration is 37%) or paraformaldehyde and blending material through a synthesis process. The described material can be one of urea, monohydroxy-melamine, dihydroxy-melamine, alkyl-substituted melamine, polyvinyl alcohol, ethyl alcohol, ethylene glycol, methyl alcohol and others or their mixture. Said resin cam be used for producing melamine foamed plastics.

Owner:濮阳绿寰宇化工有限公司

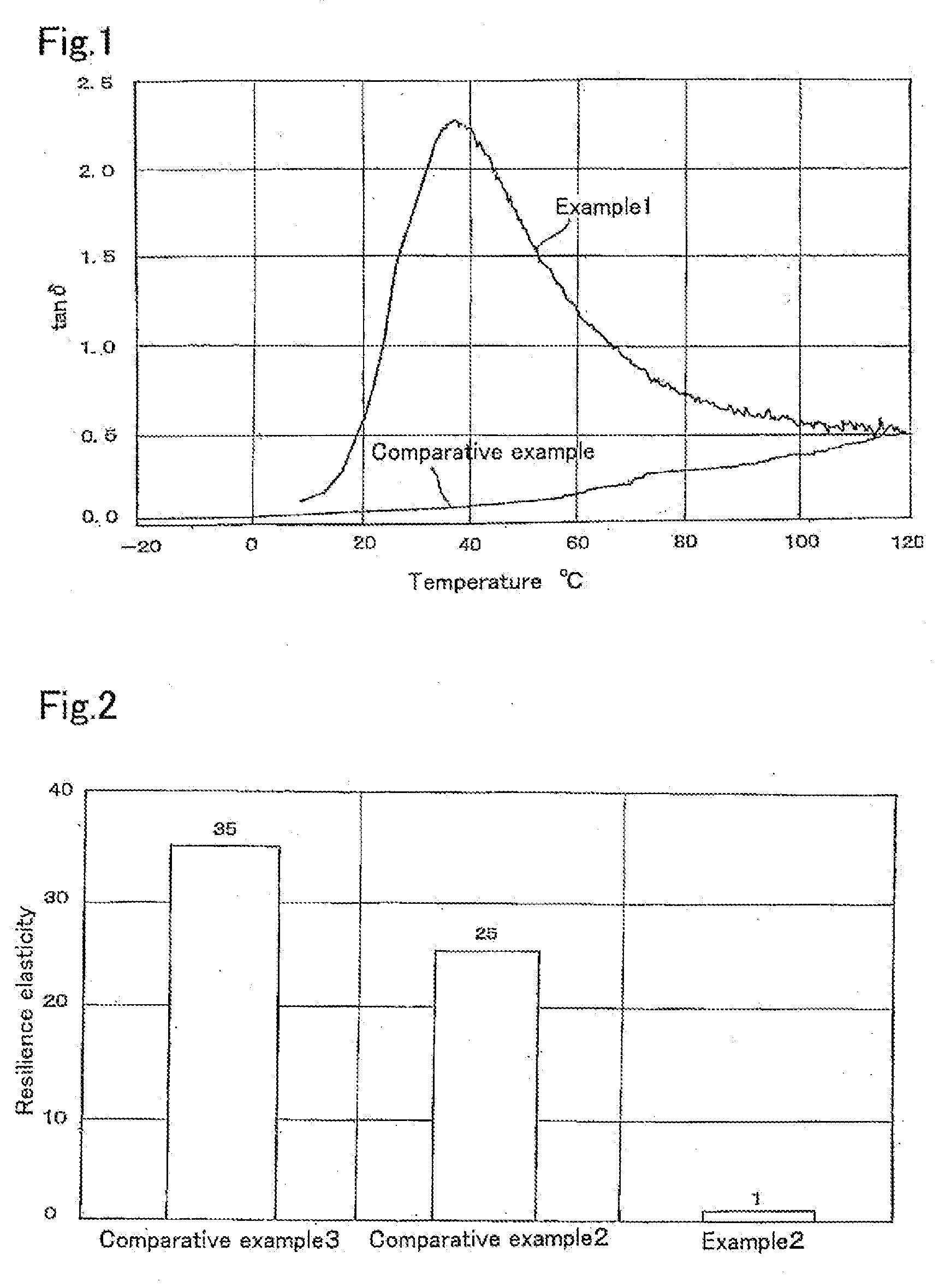

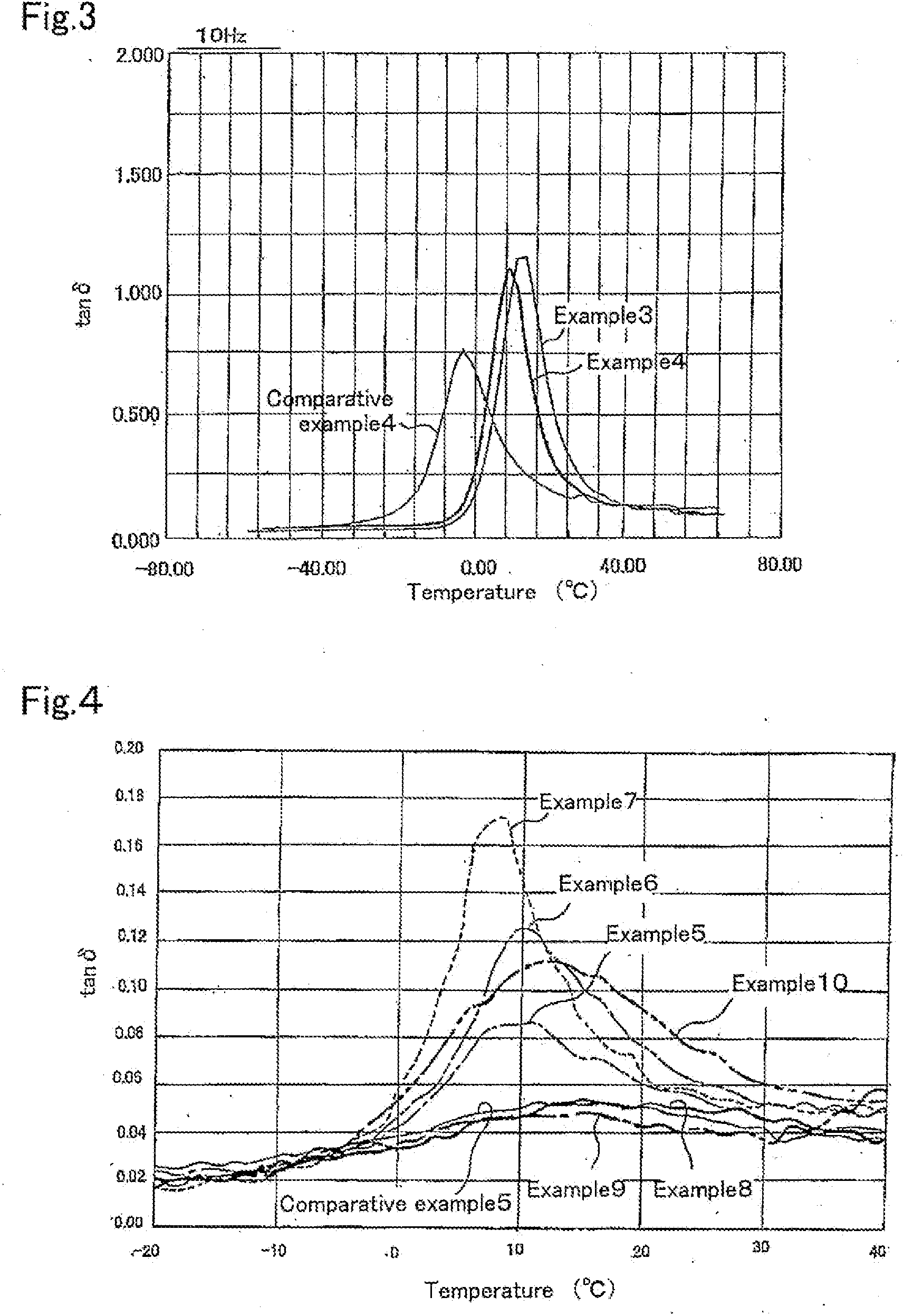

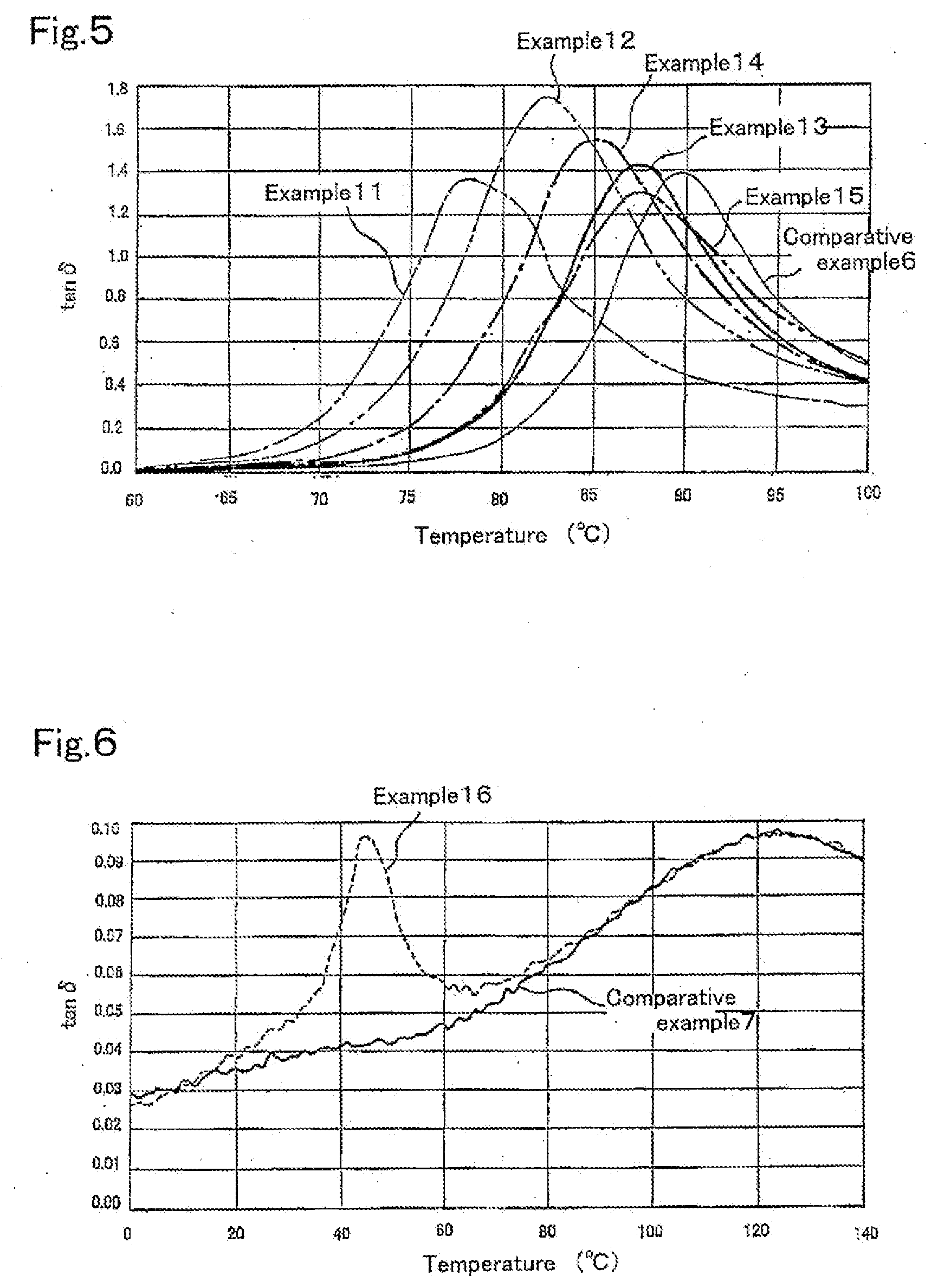

Organic damping material

InactiveUS20090325446A1Improve damping performanceEasy to processBuilding constructionsBaby linensEthyl groupPolymer

An organic damping material which by itself has excellent damping properties without being combined with other material(s), need not have a certain thickness or volume for ensuring sufficient damping performance, and is easy to process. It is characterized by comprising a polymer matrix phase and a phase dispersed therein comprising one or two or more compounds selected among-(p-toluenesulfonylamido)diphenylamine, 4,4′-bis(α,α-dimethylbenzyl)diphenylamine, octylated diphenylamine, 2,2′-methylenebis(4-ethyl-6-tert-butylphenol, 4,4′-thiobis(3-methyl-6-tert-butylphenol.

Owner:PI R & D

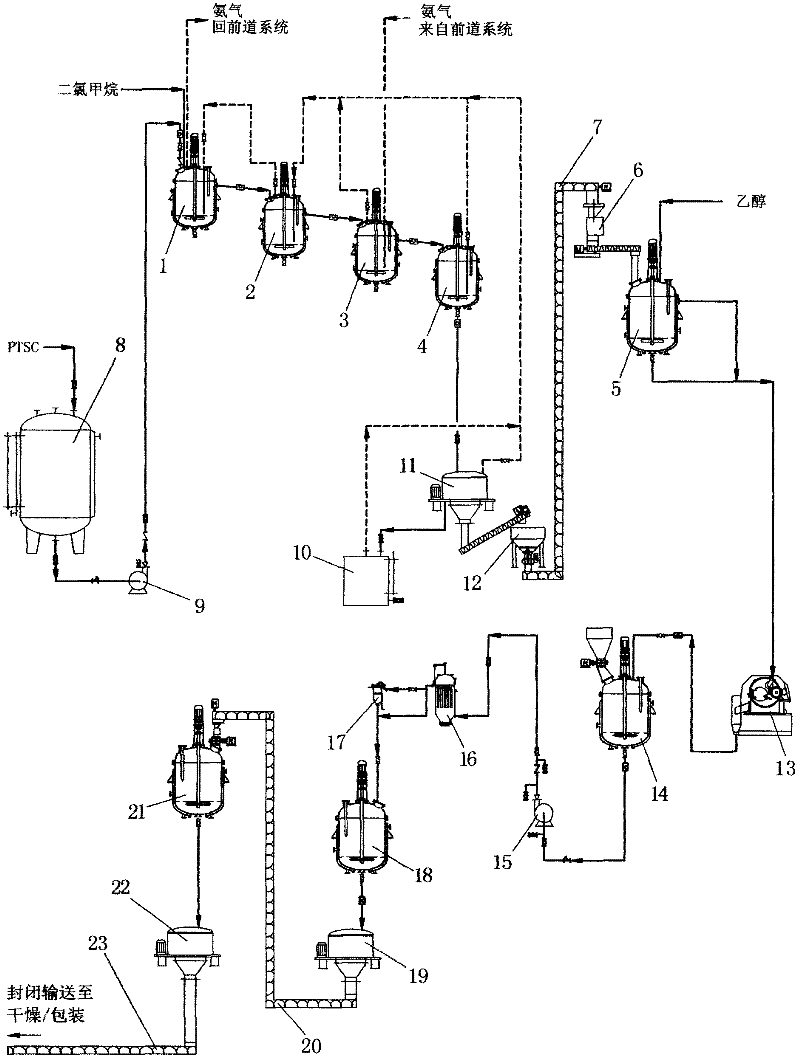

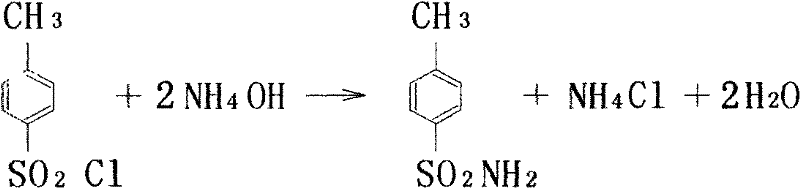

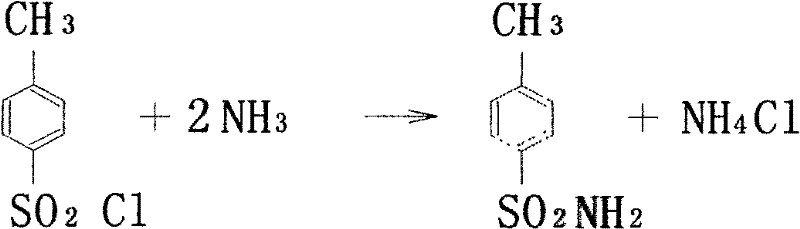

Industrial production method for toluene sulfonamide

ActiveCN102584647AReduce pollutionReduce labor intensityOrganic compound preparationSulfonic acid amide preparationMethylene DichlorideSide reaction

The invention discloses an industrial production method for toluene sulfonamide. Continuous amination is performed on paratoluensulfonyl chloride and ammonia gas in methylene dichloride solvent in a countercurrent absorbing way, then active carbon is used for decoloring, and through alcohol recrystallization and drying after water scrubbing, a qualified product can be obtained. Meanwhile, continuous production is achieved, that gas ammonia in tail gas is discharged within controlling index of national standards can be achieved, environment pollutions are reduced, and meanwhile, labor intensity is lowered. Solvent is adopted for replacing water for amination, the side reaction of hydrolyzation is stopped, and COD emission in waste water is lowered greatly while reaction conversion rate is improved.

Owner:浙江嘉化新材料有限公司

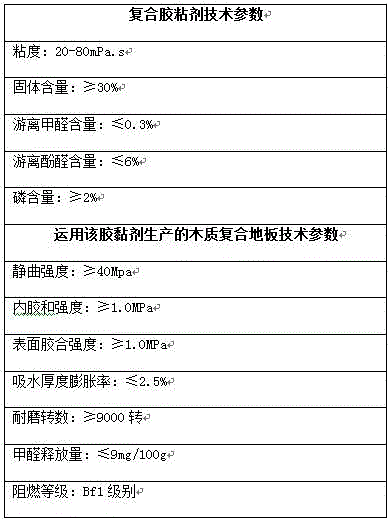

Toughened plasticized nylon 612 composite material and preparation method and applications thereof

The invention discloses a toughened plasticized nylon 612 composite material and a preparation method and applications thereof. The preparation method comprises the steps of: by taking polyolefin or polyolefin-grafted maleic anhydride or polyolefin-acrylic ester copolymer or polyolefin acrylic ester ion slats or compound thereof as a toughening agent, and N-n-butylbenzenesulfonamide or N-ethyl-o / p-toluenesulfonamide or a compound thereof as a plasticizer, adding a lubricant and an antioxidant, fusing and extruding in a double-screw extruder to obtain the toughened plasticized nylon 612 composite material. The comprehensive performances of the toughened plasticized nylon 612 composite material can meet the application demand of an automobile braking tube.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

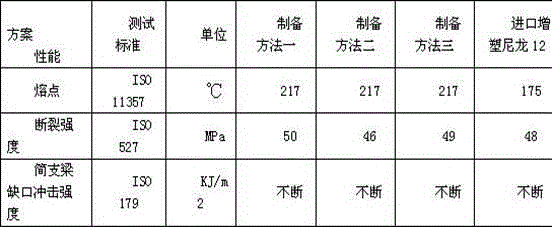

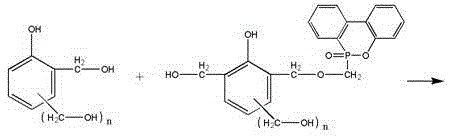

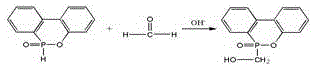

Method for preparing modified composite adhesive

ActiveCN105461874AReduce releaseImprove high temperature resistancePolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesScavengerAdhesive

The invention relates to the technical field of chemistry, and particularly relates to a method for preparing modified composite adhesive. The method comprises the following steps: weighing the following components in parts by weight: 100 parts of a formaldehyde aqueous solution, 0.1-0.5 part of an alkaline substance solution and 0.3-0.6 part of amino-terminated hyperbranched polymer PAMAM, and stirring to obtain an initial mixture; adding 20-30 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the initial mixture, heating to 50-55 DEG C, adding 35-55 parts by weight of melamine, further heating to 90-95 DEG C, and reacting to obtain an initial polycondensate; adding melamine and para-toluene sulfonamide into the initial polycondensate to obtain a second polycondensate; adding 20-30 parts by weight of urea when the second polycondensate is cooled to 70-75 DEG C, further reacting for 8-12 hours, and adding 3-5 parts of a first formaldehyde scavenger and 2-6 parts of a second formaldehyde scavenger when the temperature is reduced to 30-50 DEG C so as to obtain a first adhesive; and mixing the first adhesive and a second adhesive in a mass ratio of (3-7):1 to obtain the modified composite adhesive. The modified composite adhesive is environmentally friendly, and has a flame retarding effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

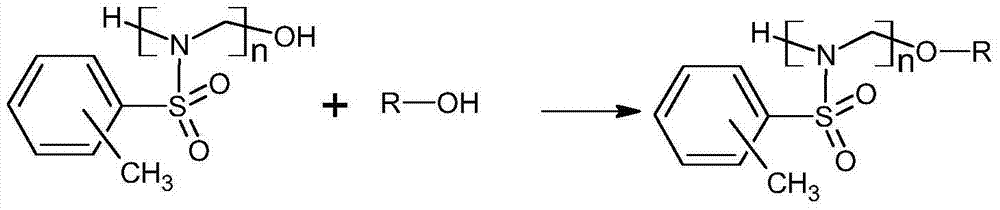

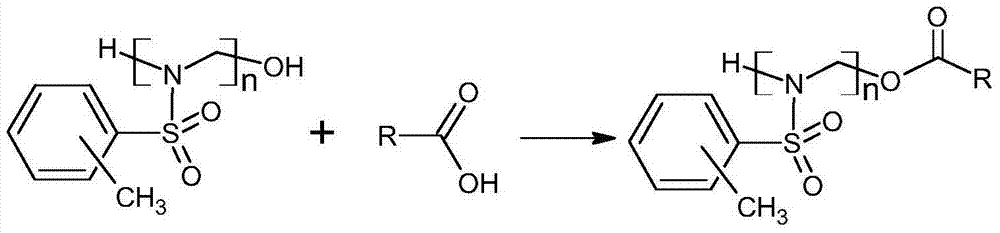

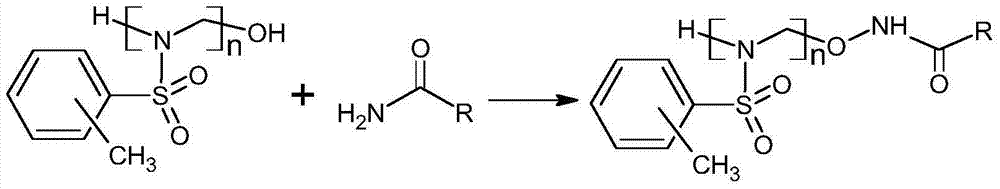

Double-coating positive thermosensitive CTP plate

ActiveCN104742492APhotosensitive materials for photomechanical apparatusForme preparationDouble coatingDissolution

The invention discloses a double-coating positive thermosensitive CTP plate, and particularly relates to the application of sulfamide-formaldehyde resin in a positive thermosensitive CTP plate. The double-coating positive thermosensitive CTP plate is used for solving the technical problem that an underexposure part of a printing plate precursor is poor in alkali resistance, the hardness becomes soft, and the plate developing latitude is decreased. According to the double-coating positive thermosensitive CTP plate, a support body of a hydrophilic surface is sequentially coated with a resin layer and a thermosensitive layer; the resin layer comprises film forming resin, alkali dissolution resin, coloring background dye, a development accelerant and the like; the thermosensitive layer comprises phenolic resin, an infrared absorption agent, a dissolution inhibitor / promoter, coloring background dye and the like; the added resin in the resin layer of the positive thermosensitive CTP plate is o / p-toluenesulfonamide formuladehyde resin with the structure as shown in the specification, wherein n is 2-3, and CH3 is o / p-methylphenyl. By adopting the technical scheme, the double-coating positive thermosensitive CTP plate has good latitude and pressure.

Owner:LUCKY HUAGUANG GRAPHICS

Positive-image thermosensitive light-sensitive composition and applications thereof

ActiveCN103885286ALow densityImprove tolerancePhotosensitive materials for photomechanical apparatusInfraredAcrylic resin

The invention relates to a positive-image thermosensitive light-sensitive composition. A coating in an unexposed part is small in density and good in tolerance level, good in solvent resistance and good in scratch resistance. The composition is characterized by comprising phenolic resin, alkali-soluble solvent-resistant acrylic resin, sulfonamide-formaldehyde resin, an infrared absorption dye, a background dye, a dissolution inhibitor, and the like. The sulfonamide-formaldehyde resin is the critical component of the composition. A edition drying step is arranged in a production process in order to remove solvent in a coating formula and the temperature can reach 120-150 DEG C, and if ortho- or para- toluene sulfonamide-formaldehyde resin is added, after being baked, the ortho- or para- toluene sulfonamide-formaldehyde resin and other resin in a thermosensitive coating can be crosslinked. After the crosslinking is performed in the unexposed part, the alkali resistance and the strength of the coating are enhanced, so that the coating loss of the unexposed part during alkaline development is reduced. In the exposed part, the association of the infrared absorption dye and the phenolic resin is opened after heat absorption, and the infrared absorption dye is liable to dissolve in an alkaline developing solution, thus increasing the developing tolerance level of the thermosensitive coating.

Owner:LUCKY HUAGUANG GRAPHICS +1

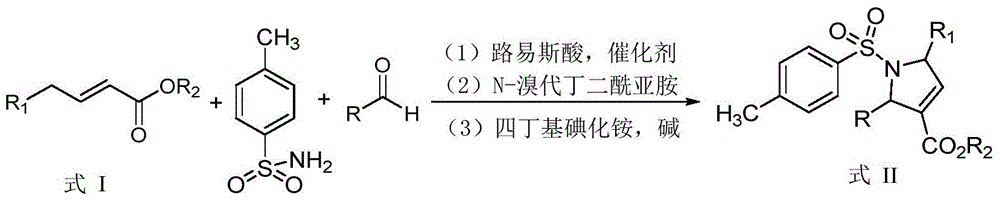

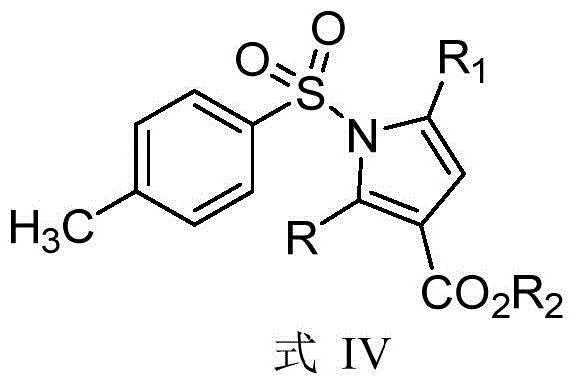

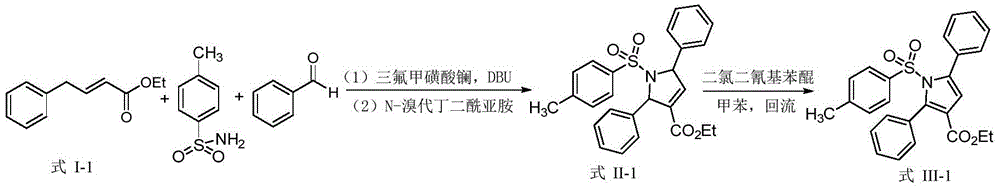

Synthetic method of dihydropyrrole and pyrrole compounds

InactiveCN105712922AHigh yieldHigh stereoselectivityOrganic chemistryIntramolecular cyclizationBenzoquinone

The invention discloses a synthetic method of dihydropyrrole and pyrrole compounds. The method comprises: reacting Alpha,Beta-unsaturated ester as raw material with para toluene sulfonamide and aldehydes under the action of an organic small-molecular catalyst 1,8-diazabicycloundercane-7-ene or 1,5-diazabycyclo[4,3,0]one-5-ene without separating an intermediate product, directly adding N-bromosuccinimide and alkali, and enabling intramolecular cyclization under mild reaction conditions so as to produce multi-group substituted dihydropyrrole compounds difficult to prepare by a conventional method, with high yield and good stereoselectivity. The synthetic method is simple, environment-friendly and high in atomic economy, enables dihydropyrrole compounds to be quickly and efficiently synthesized with one kettle, and the synthesized dihydropyrrole compounds are dehydrogenized under the action of dichloro dicyane benzoquinone to directly obtain pyrrole compounds.

Owner:SHAANXI NORMAL UNIV

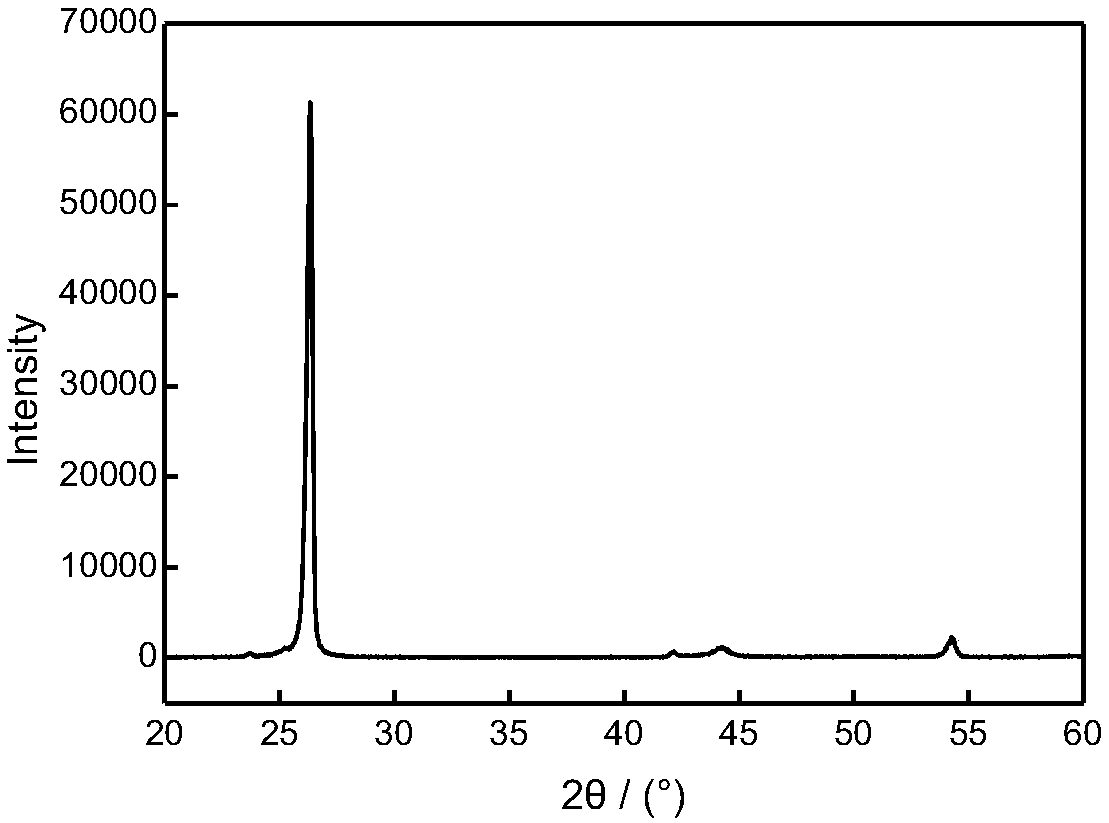

Method for preparing composite negative electrode material for lithium ion battery

InactiveUS20190036108A1Improve electronic conductivityIncreased ion mobilitySecondary cellsNegative electrodesDischarge efficiencyCarbonization

The present invention provides a method for preparing a composite negative electrode material for a lithium ion battery. The method uses the p-toluenesulfonamide modified fatty acid as the carbon source, and uses the nitrogen and sulfur element as dopant. The nitrogen / sulfur doped graphitized ordered mesoporous carbon material is prepared after high temperature carbonization, annealing and strong alkali treatment. The nano silicon powder coated with the nitrogen and sulfur doped mesoporous graphite material. The nitrogen and sulfur doped mesoporous graphite material can prevent the silicon from directly contacting the electrolyte, effectively alleviate the large volume expansion of silicon during charge and discharge, maintain the stability of the material structure, prevent the continuous formation of the SEI film, and improve the first discharge efficiency.

Owner:OPTIMUMNANO ENERGY CO LTD

Special fluorescent pigment for leather

ActiveCN103306142AGood application effectHigh fluorescenceDyeing processPolymer scienceAcrylonitrile

The invention relates to a special fluorescent pigment for leather. The special fluorescent pigment is prepared from the following raw materials: para toluene sulfonamide, tripolycyanamide, formaldehyde and polyurethane resins at a ratio of 1.0:0.8:0.6:0.3. Compared with the prior art, the fluorescent pigment has the following advantages and effects: 1, by using a pigment polymer covered by copolymers such as monomer acrylonitrile and methyl methacrylate, the emulsion stability is improved, the various fastness such as soaping fastness and bleeding fastness can be improved, and the environment pollution is reduced; 2, by using the copolymers such as monomer acrylonitrile and methyl methacrylate, the glass transition temperature of the polymer can be improved, a function of protecting a primary color body is achieved after copolymers such as monomer acrylonitrile are covered, and the sun-proof fastness is improved.

Owner:WANLONG CHEM

Melamine formaldehyde resin and synthesis technology thereof

The invention discloses a melamine formaldehyde resin and a synthesis technology thereof. The melamine formaldehyde resin comprises the following ingredients: melamine, formaldehyde, para toluene sulfonamide, sodium hydroxide, propylene glycol, alcohol and water. The synthesis technology of the melamine formaldehyde resin comprises the following steps of adding the formaldehyde into a reaction kettle, starting a stirrer, adjusting the pH value by using the sodium hydroxide, adding the melamine into the reaction kettle, uniformly raising the temperature to 80-90 DEG C in 20-30minutes, keeping the pH value at 8.5-9.0, carrying out heat preservation at 84-86 DEG C, when the turbidity degree of the reaction liquid reaches 29-32 DEG, immediately adding the para toluene sulfonamide into the reaction kettle, rapidly reducing the temperature to 60-65 DEG C, adding the propylene glycol, the alcohol and the water into the reaction kettle, regulating the pH value of the resulting solution to 8.5-9.0 by using the sodium hydroxide, cooling the resulting solution to 40-45 DEG C, and discharging the solution. The melamine formaldehyde resin prepared by the method has the characteristics of small brittleness and good stability.

Owner:HUNAN FUXIANG WOOD

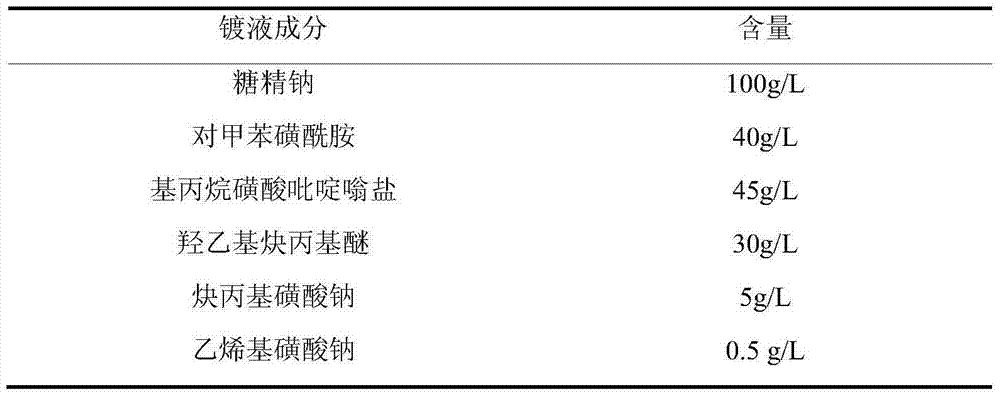

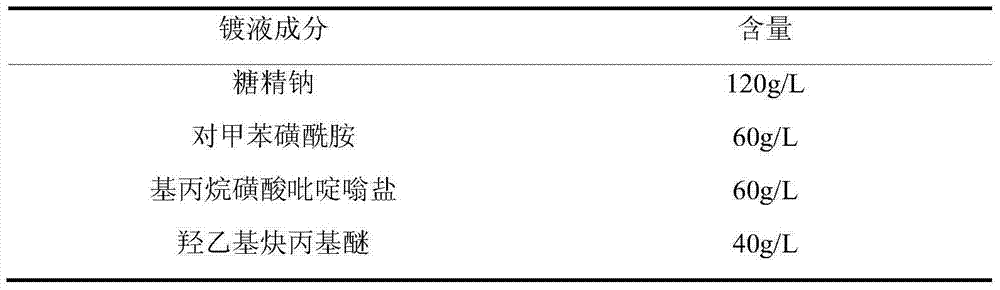

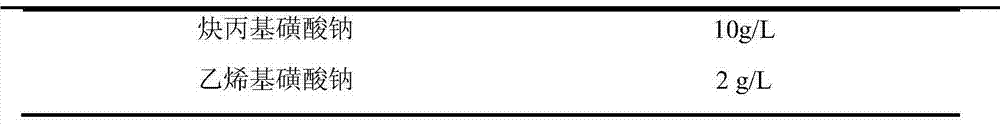

A nickel plating brightener and an electroplating method

A nickel plating brightener and an electroplating method are disclosed. The nickel plating brightener comprises 100-120 g / L of saccharin sodium, 40-60 g / L of p-toluenesulfonamide, 45-60 g / L of pyridinium hydroxy propyl sulfobetaine, 30-40 g / L of propynol ethoxylate, 5-10 g / L of sodium propynesulfonate, and 0.5-2 g / L of sodium vinylsulfonate. The nickel plating brightener combines a primary brightener, a secondary brightener and an auxiliary brightener which are prepared from intermediates, and is capable of reducing porosity of platings, improving brightness of the platings, and enhancing dispersibility and throwing power of a plating solution.

Owner:WUXI HUAYE IRON & STEEL

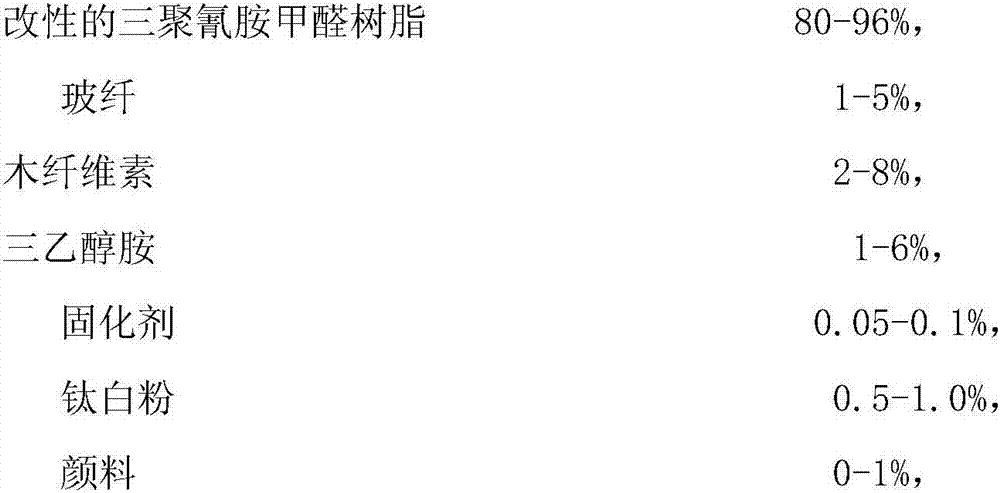

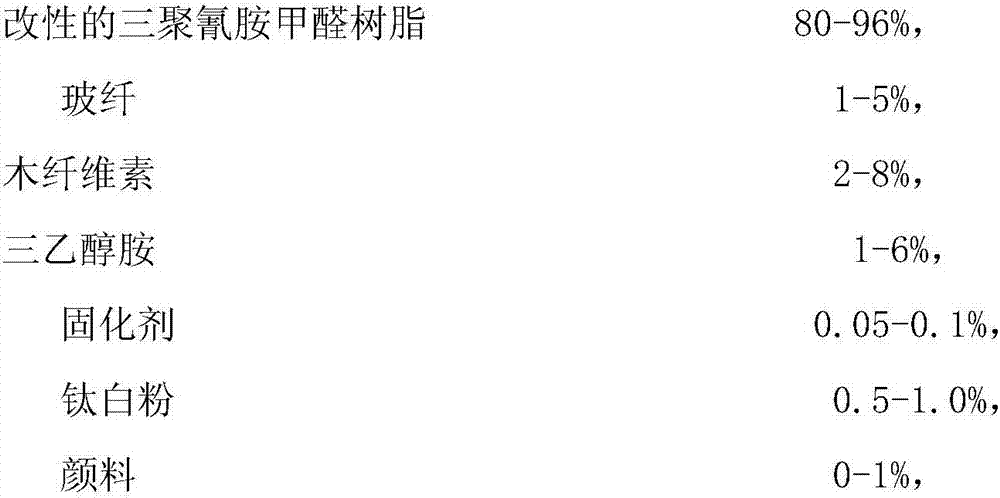

Reinforced toughened melamine mold plastics and preparation method

The invention relates to reinforced toughened melamine mold plastics and a preparation method. The melamine mold plastics are prepared from the following raw materials by weight percent: 80 to 96 percent of modified melamino-formaldehyde resin, 1 to 5 percent of glass fibers, 2 to 8 percent of wood cellulose, 1 to 6 percent of triethanolamine, 0.05 to 0.1 percent of curing agent, 0.5 to 1.0 percent of titanium dioxide, 0 to 1 percent of pigments, and the modified melamine-formaldehyde resin is prepared in the following steps: (1) adding 100 parts by weight of formaldehyde solution into a reaction kettle, adding sodium hydroxide to adjust the pH to be 8 to 9; (2) addition reaction: adding 5 to 15 parts by weight of THEIC and 5 to 15 parts by weight of PEG, beginning to heat, adding 80 to 100 parts of melamine, heating and reacting at 80 to 90 DEG C; (3) preserving the heat for 10 to 20min at the temperature of 80 to 90 DEG C, adding 5 to 15 parts by weight of para toluene sulfonamide, heating to 85 to 95 DEG C, and reacting to the end point; and (4) condensation reaction: when white precipitates are tested in the resin by utilizing the water of 4 DEG C, cooling to 75 DEG C, adjusting the pH value to 8 to 8.5, and stopping reacting.

Owner:DEQING LIANCHENG AMINO PLASTIC PROD CO LTD

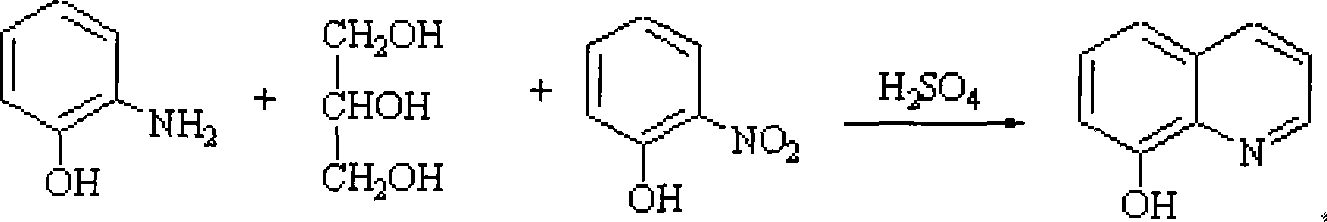

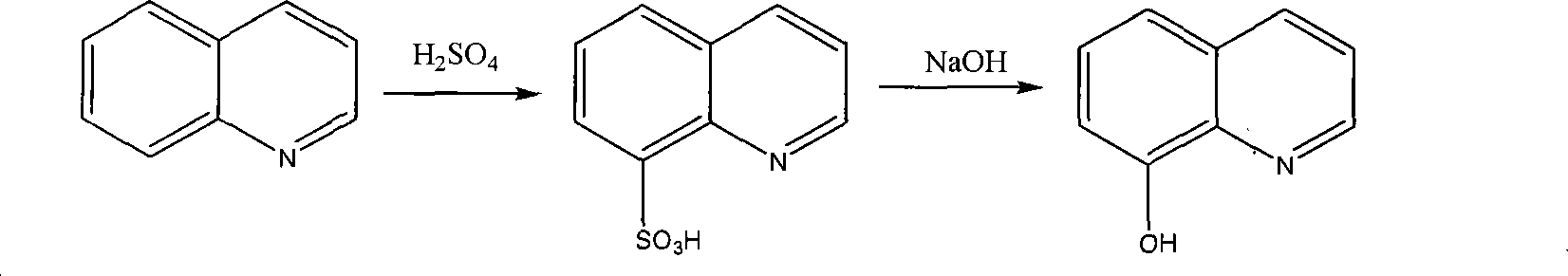

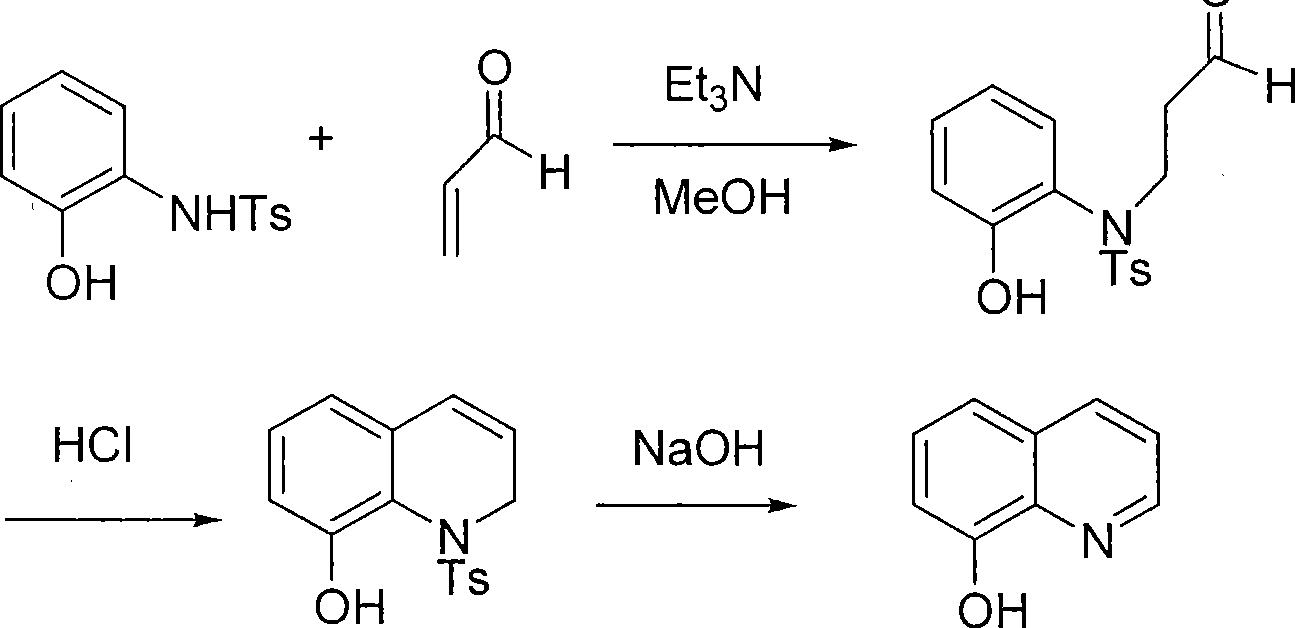

Production technique of 8-hydroxyquinoline

InactiveCN101161643AThe reaction conditions are mild and safeHigh yieldOrganic chemistryQuinoline8-Hydroxyquinoline

The present invention discloses a production technics for a 8-hydroxide quinoline, which includes the following synthetic procedures that: firstly 2-N- p-toluenesulfonyl amino phenol is mixed with ethylamine and methanol, cooled, and dripped with acrolein, after dripping, the mixture is stirred continuously for reaction, then added with hydrochloric acid, stirred for reaction under raised temperature to produce an intermediate of p-toluenesulfonyl-8-hydroxide hydrogenated quinoline, secondly, the solution as above is added with solid sodium hydroxide, the temperature of the mixed solution is raised, and then undergoes circumfluence cooling down, then hydrochloric acid is used to regulate the pH=7.5-7.8 and, thirdly, water is added into the solution as above, temperature is raised and water steam distillation is carried out to obtain the high-purity 8-hydroxide quinoline. Compared with the preparation method in the prior art, the present invention has simple operation, economized investment on the equipment, high yields, low fabrication cost, and suitability for industrialized fabrication. The actual molecular yield of 8-hydroxide can reach to more than 85 percent of that of 8-hydroxyl quinoline, based on the amount of 2-N- p-toluenesulfonyl amino phenol.

Owner:CHIZHOU WANWEI CHEM

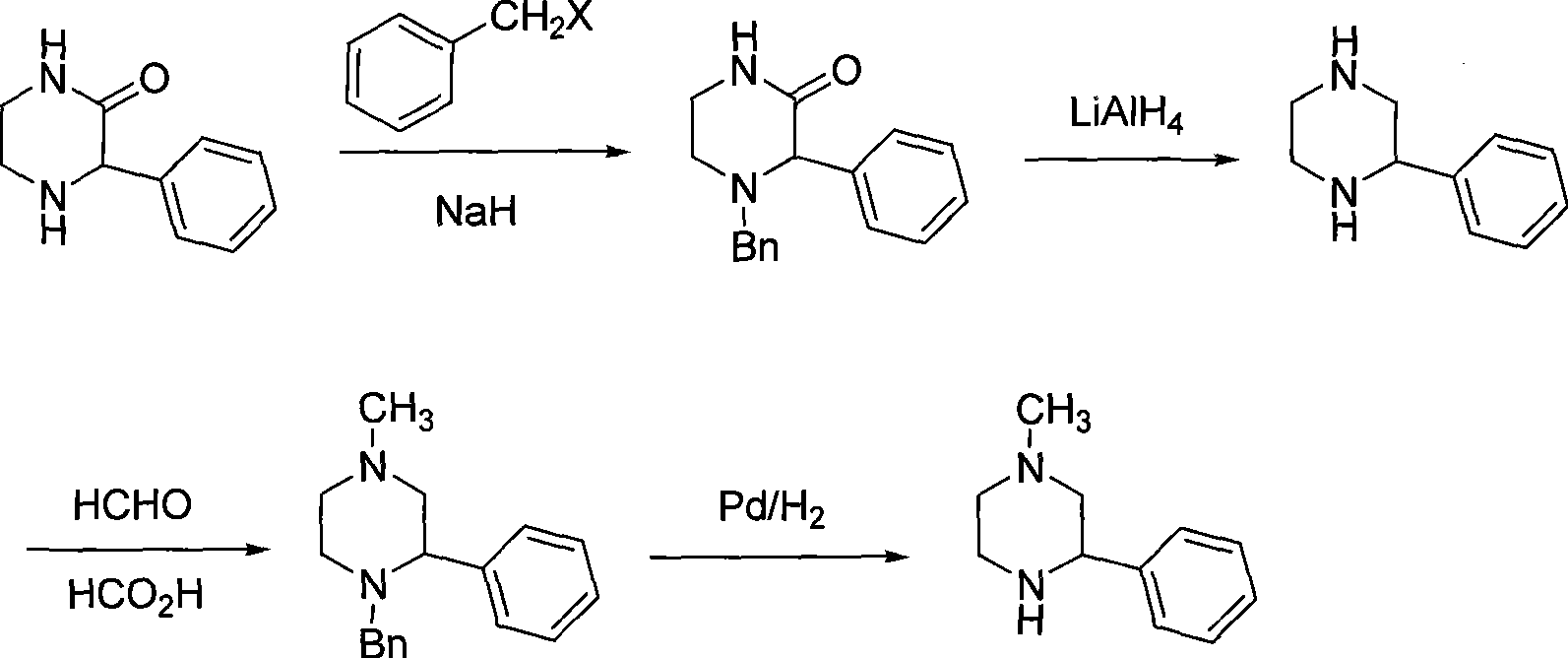

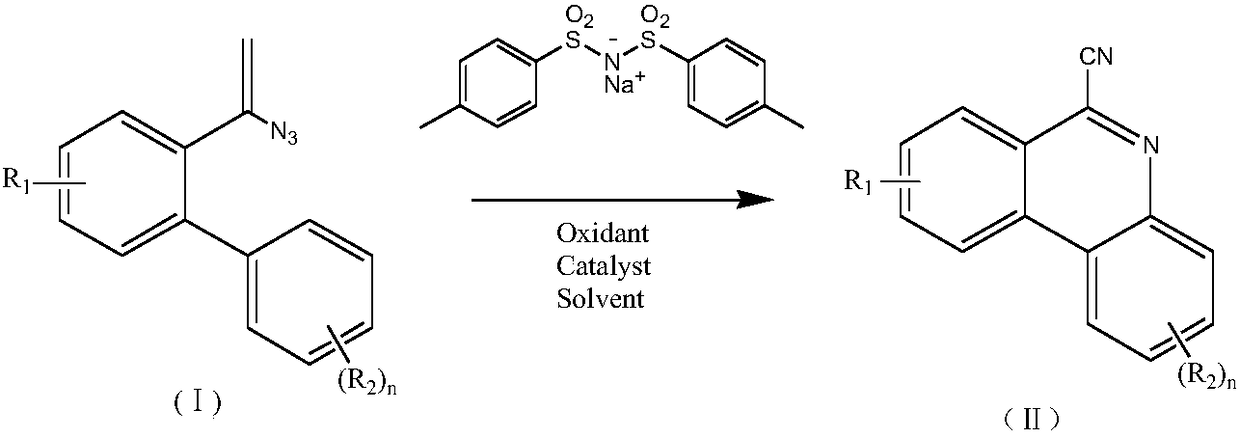

Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane

ActiveCN110317201AIncreased chiral inducibilityHigh yieldOrganic chemistryHydrazine compoundSynthesis methods

The invention relates to an asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane. N-benzyl-butene imidodicarbonic diamide is taken as a raw material, in presence of a chiral squaramidecatalyst (III), the N-benzyl-butene imidodicarbonic diamide and N-para-toluene sulfonyl-N'-propylene imidogen hydrazine (II) are subjected to an asymmetric [2+4] addition reaction, and 8-benzyl-2-para-toluene sulfonamide-7,9-dioxo-(1S,6R)-2,8-diazabicyclo[4,3,0]-3-alkene nonane is obtained; through the steps of recrystallization, reduction, acid-catalyzed hydrolysis and reduction, the (S,S)-2,8-diazabicyclo[4,3,0]nonane is obtained. The synthesis method is simple, the yield of the asymmetric catalysis product is high, the enantioselectivity of the product through recrystallization can reach 90% or above, and the asymmetric synthesis method is mild in condition, simple to implement, low in production cost and capable of being used for industrialized production.

Owner:WUHAN UNIV OF TECH

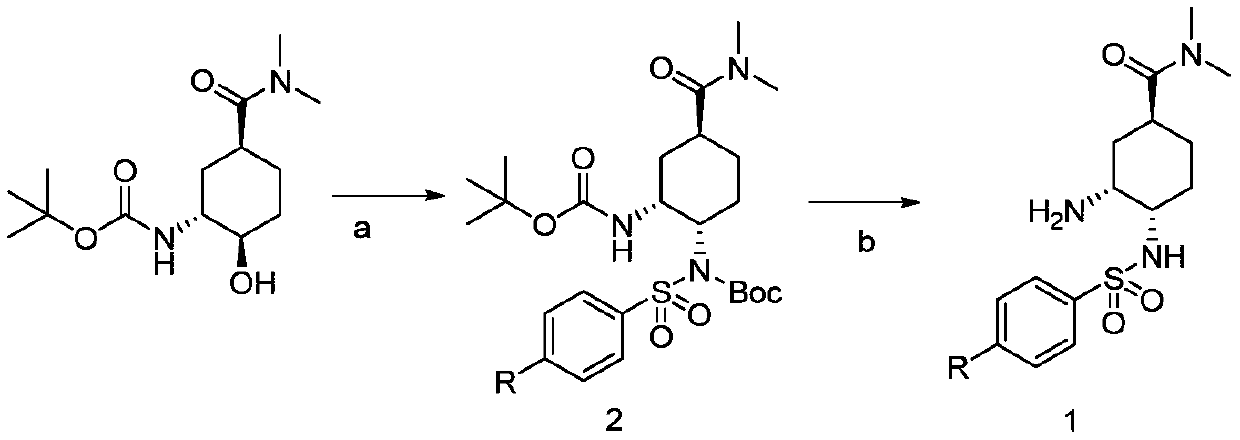

Preparation method of Edoxaban tosylate intermediate and intermediate compound

ActiveCN109836360AEasy to introduceHigh reaction conversion rateSulfonic acid amide preparationBulk chemical productionTert-Butyloxycarbonyl protecting groupSodium azide

The invention provides a preparation method of an Edoxaban tosylate intermediate, the method comprises the following reaction steps: step a, under a certain temperature condition, adding dimethylformamide substituted cyclohexane, triphenylphosphine (PPh3)) and diethyl azodicarboxylate (DEAD) in a solvent, and then adding N-(t-butyloxycarboryl) p-nitrobenzenesulfonamide or N-(t-butyloxycarboryl) p-toluene sulfonamide for reacting to obtain a chirally-turned compound 2; and step b, removing Boc under a strong acid condition so as to obtain a compound 1; the invention further provides intermediate compounds of the compound 1 and the compound 2 in the preparation of the Edoxaban tosylate intermediate; the amino introduction process in the preparation method is simple, the reaction conversion rate is relatively high, and industrialization is easy to realize, so that the use of hazardous chemical sodium azide is avoided, the process safety is improved, and the production yield is improved.

Owner:南京恩泰医药科技有限公司

Raw silk bentonite cutting fluid

InactiveCN104804853AImprove the lubrication effectImprove extreme pressure lubrication performanceLubricant compositionSodium PyrithioneSodium biphosphate

The invention discloses a raw silk bentonite cutting fluid which comprises the following raw materials by weight: 1 to 2 parts of sodium biphosphate, 0.5 to 2 parts of zinc pyrithione, 0.8 to 1 part of N-ethyl-o / p-toluene sulfonamide, 3 to 4 parts of nano bentonite, 3 to 4 parts of polylactic acid, 16 to 20 parts of dimethyl sulfoxide, 4 to 5 parts of raw silk, 20 to 30 parts of triethanolamine borate, 2 to 3 parts of span 80, and 200 to 300 parts of deionized water. A fibroin lubricating liquid (an intermediate product of the raw silk bentonite cutting fluid) takes natural silk as a main material, thereby being nontoxic, free of pollution, and high in lubricity; triethanolamine borate, which is excellent in extreme pressure lubricity, rust-proof, anti-bacterial, capable of sterilizing and the like, is mixed with the fibroin lubricating liquid to obtain a liquid mixture; the liquid mixture is modified with polylactic acid. Therefore, the fracture strength and wettability of a blend membrane can be improved; a lubricating film layer formed on the friction metal surface can be more stable; the extreme pressure anti-wear property and reaction activity are improved effectively.

Owner:ANHUI JINGYI GLASS MACHINERY

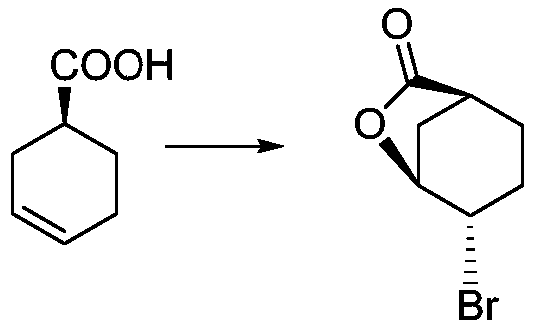

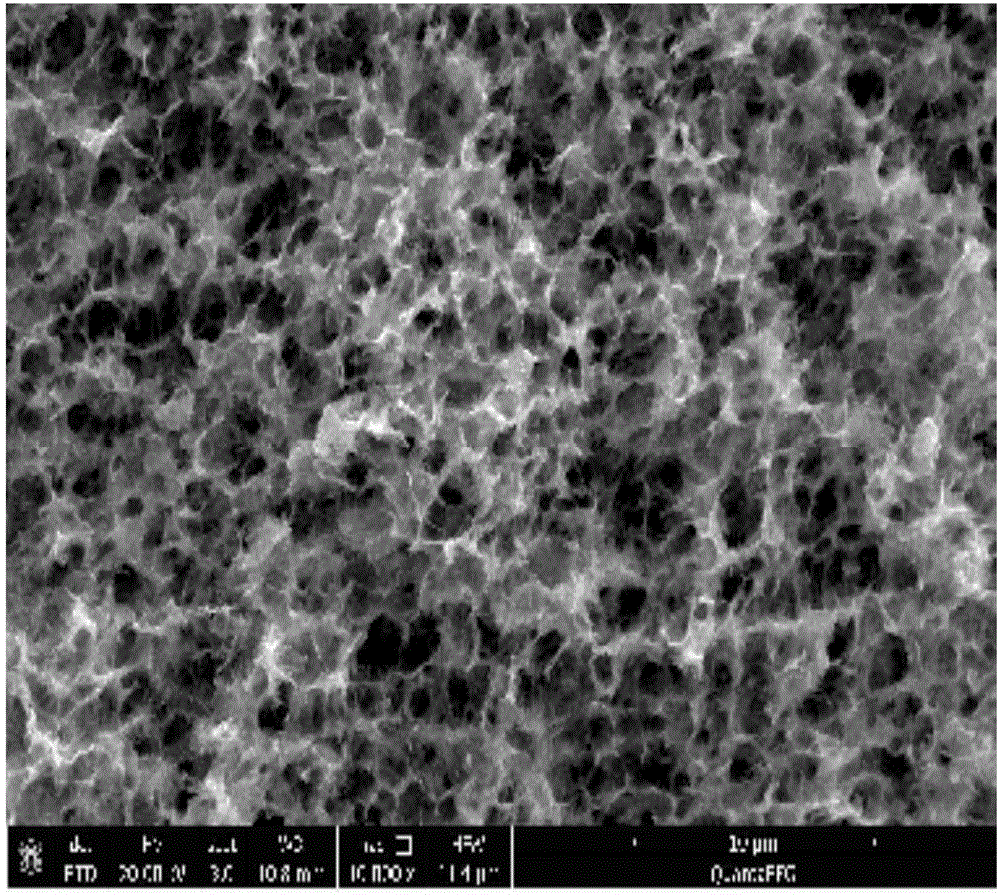

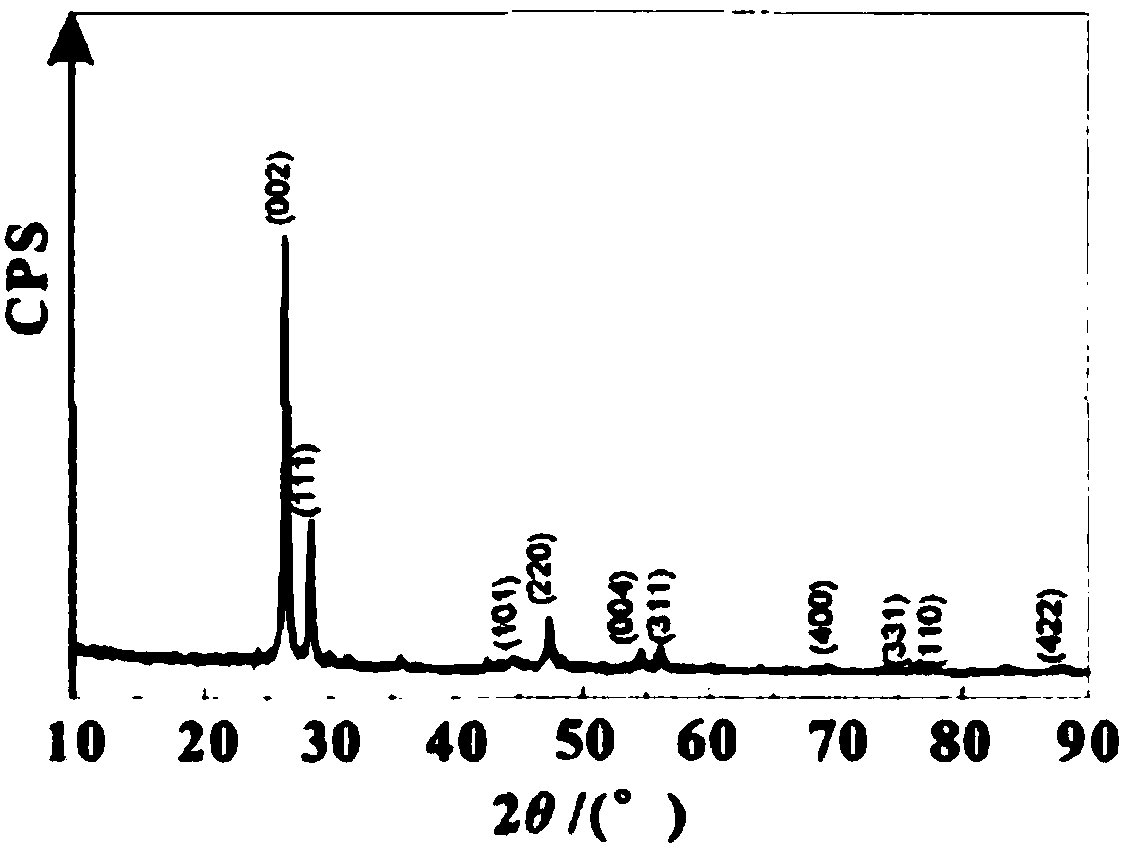

Preparation method of electromagnetic shielding material based on carbon material, polypyrrole and alpha-iron sesquioxide

The invention relates to preparation methods of electromagnetic shielding materials, in particular to a preparation method of an electromagnetic shielding material based on a carbon material, polypyrrole and alpha-iron sesquioxide, and aims to solve the problem that existing single-component electromagnetic shielding materials are disadvantageous in performance. The preparation method includes: 1, preparing a carbon material subjected to acid treatment; 2, preparing the carbon material impregnated; 3, preparing the carbon material subjected to high-temperature treatment; 4, impregnating the carbon material subjected to high-temperature treatment in a mixed solution of FeCl3.6H2O and p-toluene sulfonamide, and freely reacting with pyrrole to complete the preparation method. The preparation method is used for preparing the electromagnetic shielding material based on the carbon material, polypyrrole and alpha-iron sesquioxide.

Owner:NORTHEAST FORESTRY UNIVERSITY

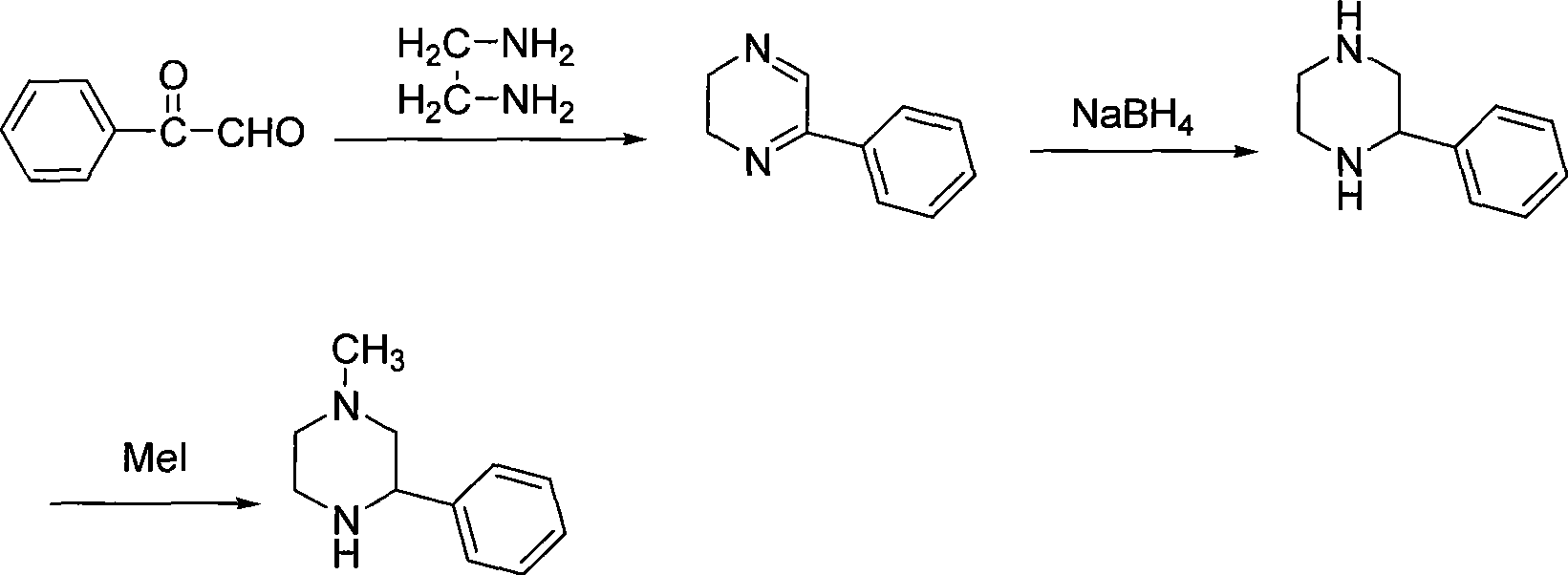

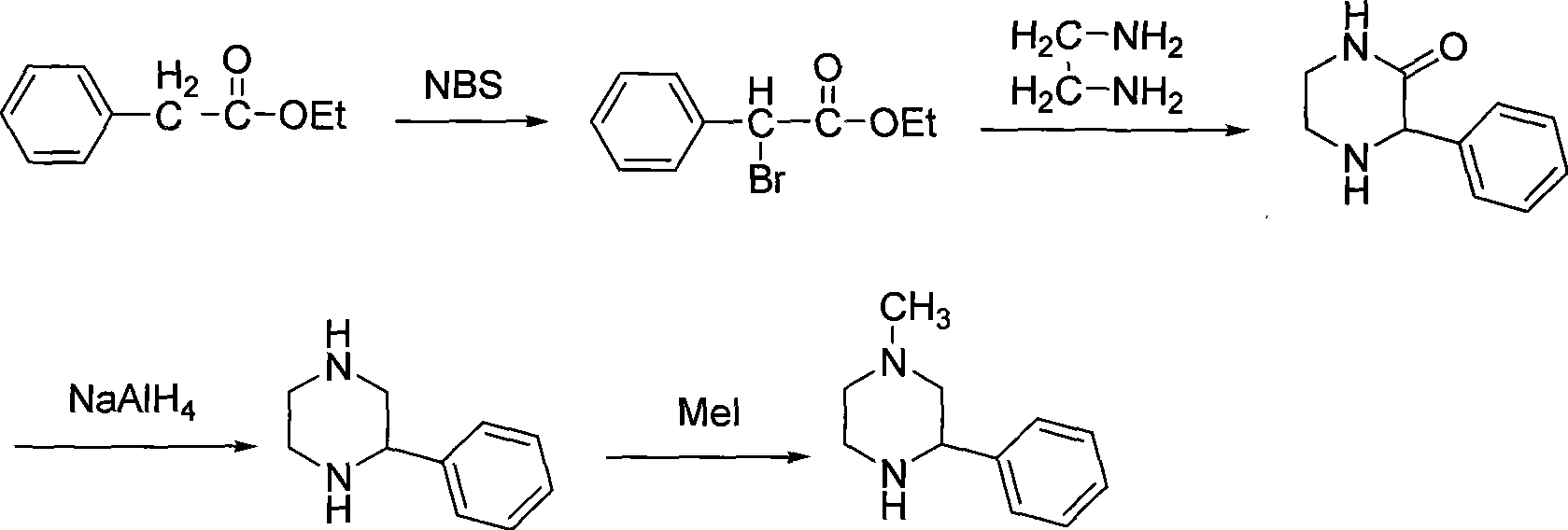

Preparation of medicament intermediate 1-methyl-3-phenyl piperazine

The invention relates to a method for preparing a medicine intermediate, namely 1-methyl-3-phenyl-piperazine. Epoxy phenylethane and N-methyl ethanolamine react for ring opening in a methylbenzene solution and further react with thionyl chloride to obtain N-(2- chloroethyl)-N-methyl-2-chloro-2-phenylethylamine hydrochloride, the hydrochloride reacts with toluene sulfonamide and sodium hydroxide in a DMF solution to obtain 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine, the 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine reacts with concentrated hydrochloric acid to remove sulfonyl, and a product is obtained through neutralization extraction and recrystallization. Compared with the prior art, the method for preparing the 1-methyl-3-phenyl-piperazine has the advantages of low cost of selected raw materials, cost conservation, few synthesis steps, convenient and safe operation, simple post-treatment, high reaction yield, high product purity, good quality, and suitability for industrialized application.

Owner:上海津力药业股份有限公司

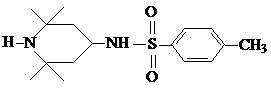

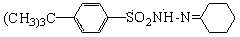

Method for preparing light stabilizer 4-p-toluenesulfonamide-2,2,6,6-tetramentylniperidine

The invention discloses a method for preparing a light stabilizer 4-p-toluenesulfonamide-2,2,6,6-tetramentylniperidine. P-toluenesulfonyl chloride and 4-amino-2,2,6,6-tetramentylniperidine which are taken as raw materials are reacted in the presence of a catalyst and a solvent to form the 4-p-toluenesulfonamide-2,2,6,6-tetramentylniperidine. The 4-p-toluenesulfonamide-2,2,6,6-tetramentylniperidine is prepared from the p-toluenesulfonyl chloride and the 4-amino-2,2,6,6-tetramentylniperidine, the separation and purification processes are simple, the reaction time is short, the yield of the product is over 90 percent, the product purity is high, energy consumption is low, environmental pollution is light, the cost is low, and the method is an ideal process for industrial production.

Owner:南通惠康国际企业有限公司

Automotive trim flame-resistant material and preparing method thereof

InactiveCN105037966AImprove flame retardant performanceQuickly turn offPolyethylene terephthalate glycolPolyvinyl alcohol

The invention discloses an automotive trim flame-resistant material and a preparing method thereof. The material comprises, by weight, 50-80 parts of polypropylene resin, 20-60 parts of anilmomethyl triethoxy silane, 10-40 parts of glass fiber reinforced polyethylene terephthalate, 20-30 parts of N-ethyl-p-toluenesulfonamide, 40-50 parts of barium sulfate, 40-50 parts of polyvinyl alcohol, 10-30 parts of dimethyl terephthalate, 20-60 parts of paraformaldehyde, 40-50 parts of arsenic trioxide, 2-8 parts of potassium oxide, 10-20 parts of dicyanodiamine, and 20-40 parts of adipic acid dihydrazide. According to the preparing method, the polypropylene resin, the anilmomethyl triethoxy silane, the glass fiber reinforced polyethylene terephthalate, the N-ethyl-p-toluenesulfonamide, the barium sulfate, the polyvinyl alcohol, the paraformaldehyde, the arsenic trioxide, the potassium oxide, the dicyanodiamine and the adipic acid dihydrazide are evenly mixed through a high-speed mixing machine for plasticizing fusion, dimethyl terephthalate injection is conducted at the same time, and the constituents are extruded after being mixed. The flame resistance of the automotive trim flame-resistant material is high.

Owner:浙江联益智能科技有限公司

Fluorinated thin film coating and preparation method thereof

The invention provides fluorinated thin film coating. The fluorinated thin film coating is prepared from the following raw materials in parts by weight: 0.1 to 0.3 part of 1H,1H,2H,2H-perfluorodecyltriethoxysilane, 0.7 to 1 part of zinc acetylacetonate, 1 to 2 parts of calcium fluoride, 4 to 5 parts of ammonium bicarbonate, 1 to 1.5 parts of vanadyl sulfate hydrate, 6 to 7 parts of sodium tungstate dihydrate, 20 to 30 parts of a silane coupling agent KH570, 5 to 7 parts of methyltriethoxysilane, 60 to 70 parts of 2 percent to 3 percent ammonia water solution, 0.3 to 0.4 part of aminopropyltriethoxysilane, 0.1 to 0.2 part of butyl oleate, 0.3 to 1 part of sodium butylnaphthylsulfonate, 1 to 3 parts of polyethylene glycol 1000 and 0.1 to 0.2 part of p-toluenesulfonamide. The silane coupling agent KH570 is used for carrying out modification treatment, and molecules of the silane coupling agent KH570 are grafted on tungsten-doped vanadium dioxide powder particles, so that the hydrophobicity of modified particles is effectively improved, and the surface strength of a coating film is further improved.

Owner:TONGLING FOUNDER PLASTICS TECH

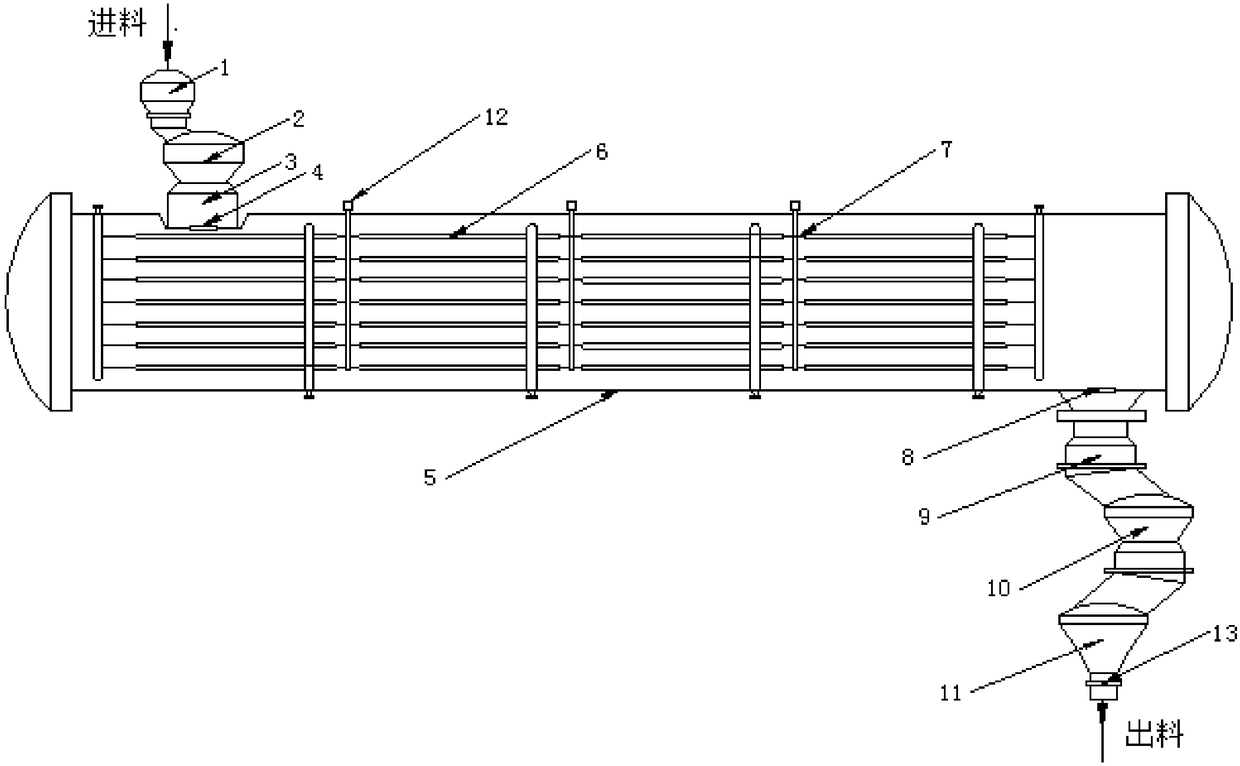

Para toluene sulfonate continuous drying method

PendingCN108489238AEvenly distributedEasy to evaporateDrying solid materials without heatDrying machines with progressive movementsAlcoholBoiling point

The invention discloses a para toluene sulfonate continuous drying method which adopts a crawler type continuous drying method. A baffling type channel formed by an upper heating slab and a lower heating slab which are on a crawler and middle solid square steel allows materials to be distributed uniformly, the surface is heated uniformly, a fluid medium flows without a dead angle, and water, alcohol and low boiling impurities are evaporated more easily; with the combination of vacuumizing, a feeding bin and a discharge bin are designed like a space capsule, so that the impurities such as waterand alcohol are removed more easily; and the para toluene sulfonate continuous drying method has the advantages of high drying rate, high evaporation intensity, short time and stable product quality.

Owner:浙江嘉化新材料有限公司 +1

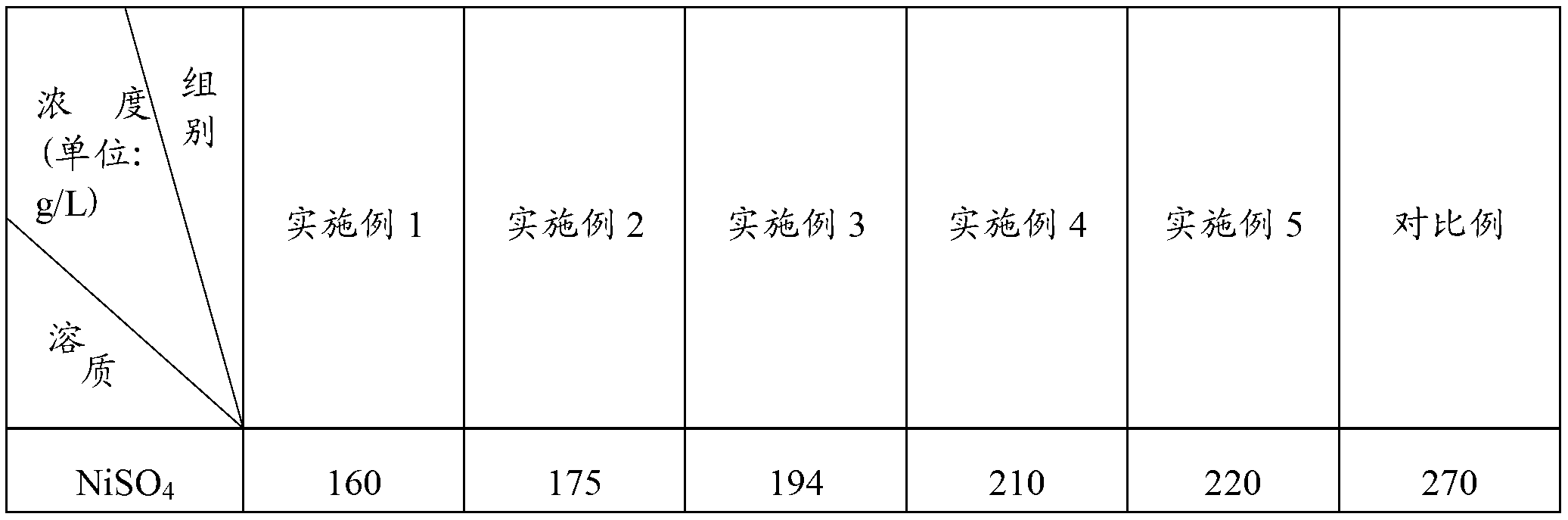

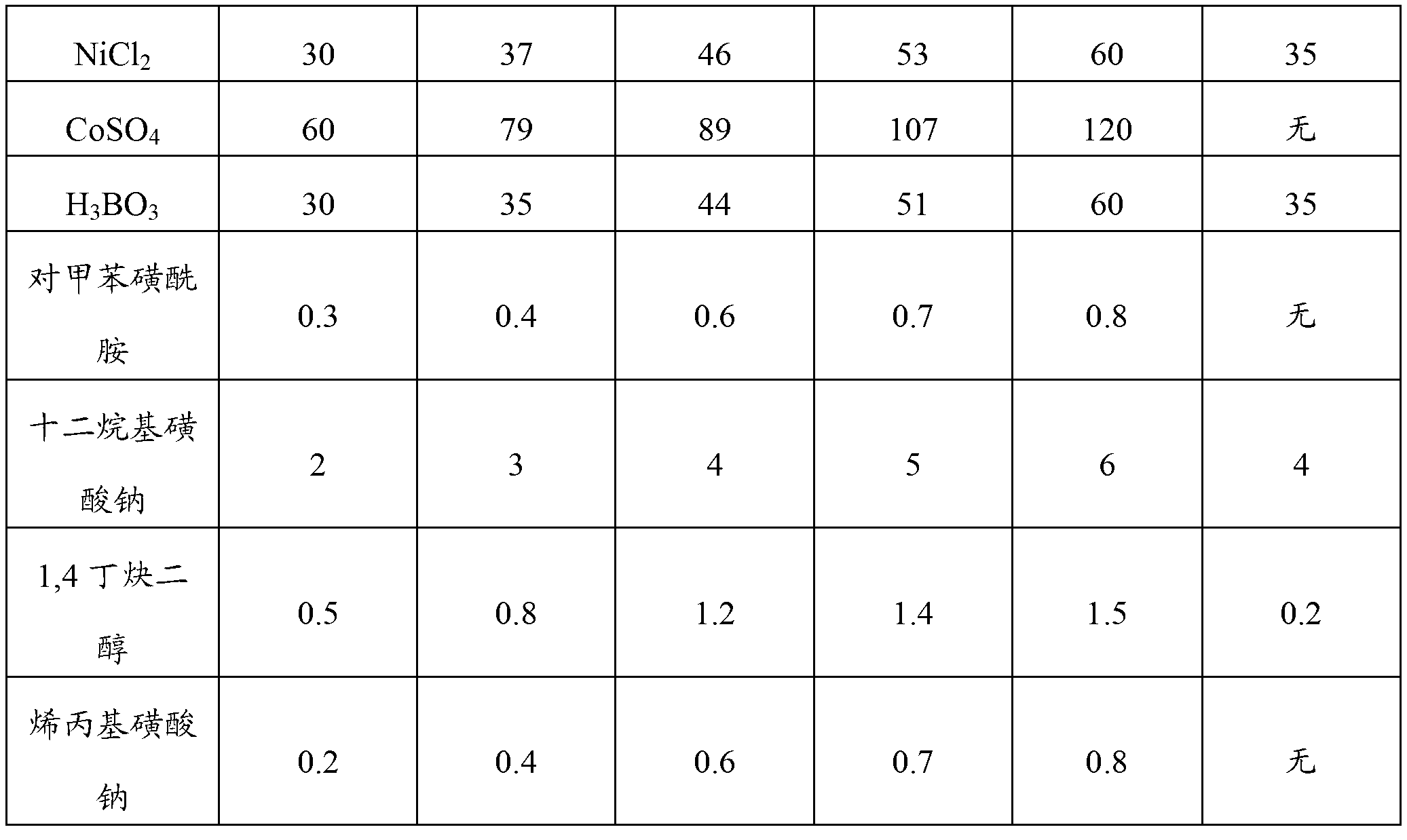

Electroplating solution and application thereof

The invention relates to an electroplating solution. The solute comprises 160-220 g / L nickel sulfate, 30-60 g / L nickel chloride, 60-120 g / L cobaltous sulfate, 30-60 g / L boric acid, 0.3-0.8 g / L para toluene sulfonamide, 0.5-1.5 g / L 1,4-butynediol and 0.2-0.8 g / L sodium alkyl sulfonate. The solvent is water. The diamond saw band prepared by the electroplating solution has the advantages of uniform coating, high coating hardness, great force for holding diamond, great effective cutting surface, and obviously higher cutting efficiency and cutting power. Under the conditions of the same holding force, the coating thickness of the prepared diamond saw band is obviously lowered, thereby lowering the production cost of the diamond saw band, increasing the void ratio, being beneficial to discharge of cutting powder, and enhancing the cutting efficiency. Besides, the invention also relates to application of the electroplating solution.

Owner:JIANGSU XIEXIN SOFT CONTROL EQUIP TECH DEV

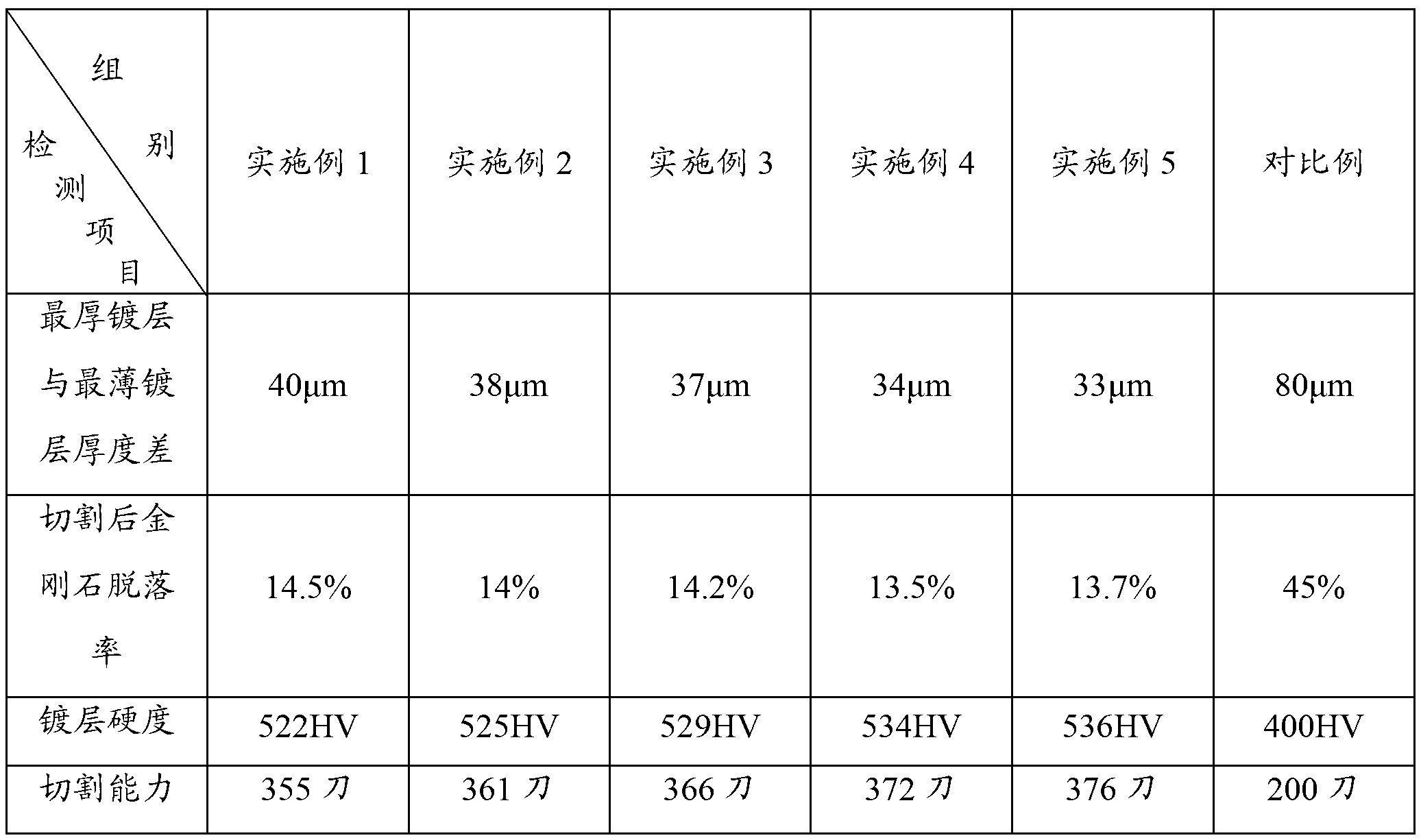

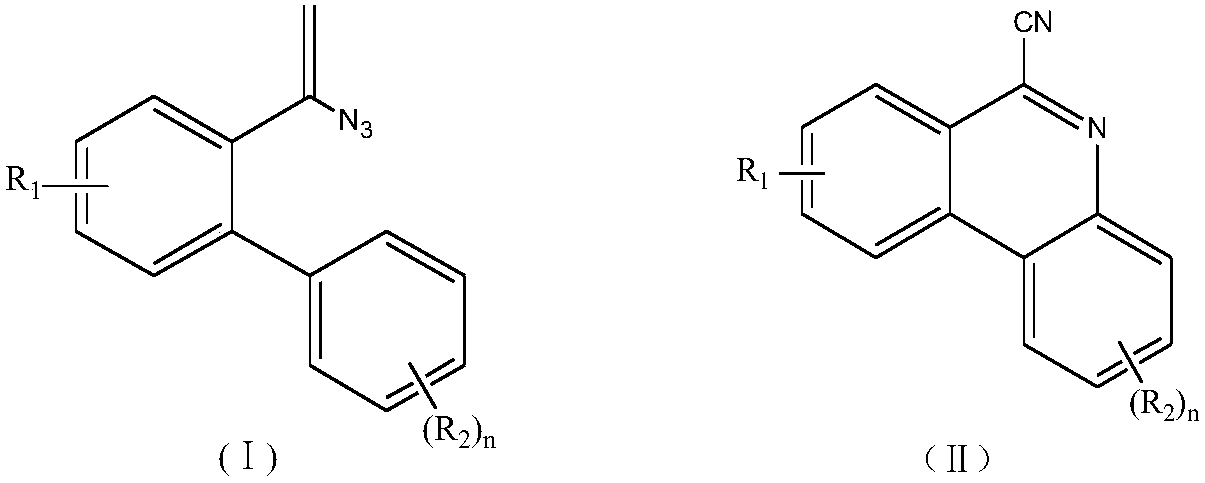

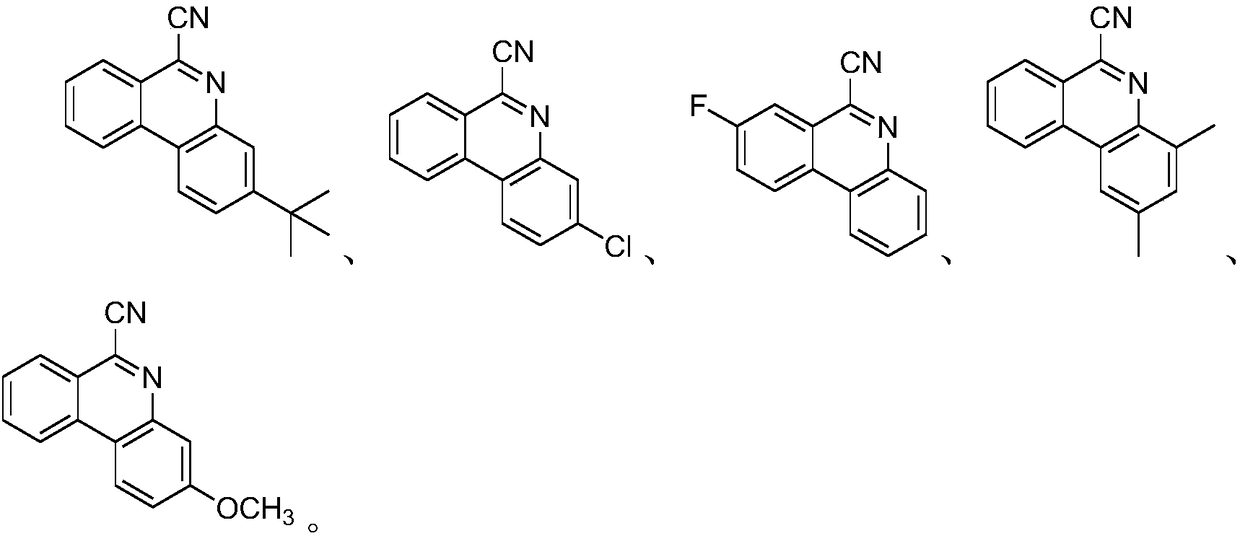

Method for synthesizing 6-cyanophenanthridine compounds

InactiveCN109422687AGood substrate adaptabilityAchieve aromatization/cyanationOrganic chemistrySynthesis methodsNitrogen source

The present invention provides a method of synthesizing 6-cyanophenanthridine compounds. The synthesis method comprises the steps of: taking a substituted azide terminal olefin compound represented bya formula (I) as an initial substance, using sodium ditosylamide as a nitrogen source, conducting a reaction at 60-120 DEG C for 3-6 hours under the action of a silver catalyst, an oxidizing agent and a solvent, and conducting separation purification on the reaction solution to obtain the 6-cyanophenanthridine compound represented by the formula (II). The synthesis method of the invention has thecharacteristics of low environmental hazard, mild reaction conditions, simple operation and the like.

Owner:ZHEJIANG UNIV OF TECH

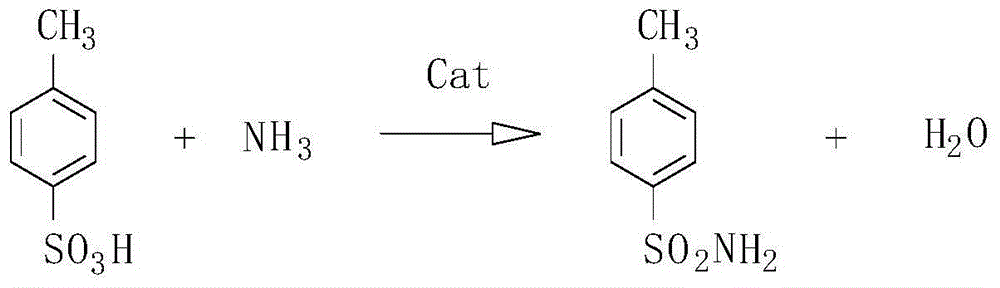

Method for preparing para toluene sulfonamide by directly amidating para-toluenesulfonic acid

ActiveCN104945288AHigh reactivityIncrease electropositivityOrganic compound preparationSulfonic acid amide preparationTosylic acidFiltration

A method for preparing para toluene sulfonamide by directly amidating para-toluenesulfonic acid comprises the following steps: (1) anhydrous para-toluenesulfonic acid is dissolved in dichloromethane, a catalyst, namely organic boronic acid, and a 5A molecular sieve are added in a mixed solution, and the mixed solution is uniformly stirred for a certain time under the condition that the temperature is controlled to be -10 to 0 DEG C; (2) an ammonia gas is introduced at the -10 to 0 DEG C for reaction; (3) after the reaction is finished, suction filtration is conducted on the reaction liquid to remove the molecular sieve, and then washing is respectively performed once with an acid solution, an alkali solution and a salt solution; (4) an organic phase is dried through anhydrous sodium sulfate, then a drying agent is removed, a dichloromethane solvent is subjected to distillation recovery, and crude para toluene sulfonamide is obtained; (5) weighing is performed after washing with distilled water and drying, and the product purity is analyzed through liquid chromatography. The complexation is generated between organic boric acid energy and oxygen on a sulfonic acid molecule, the reaction activity of the para-toluenesulfonic acid is improved, ammonia molecules are easily combined with sulfur to generate amide, the whole reaction energy consumption is low, no waste acid is discharged, and the yield of para toluene sulfonamide is about 40%.

Owner:浙江嘉福新材料科技有限公司

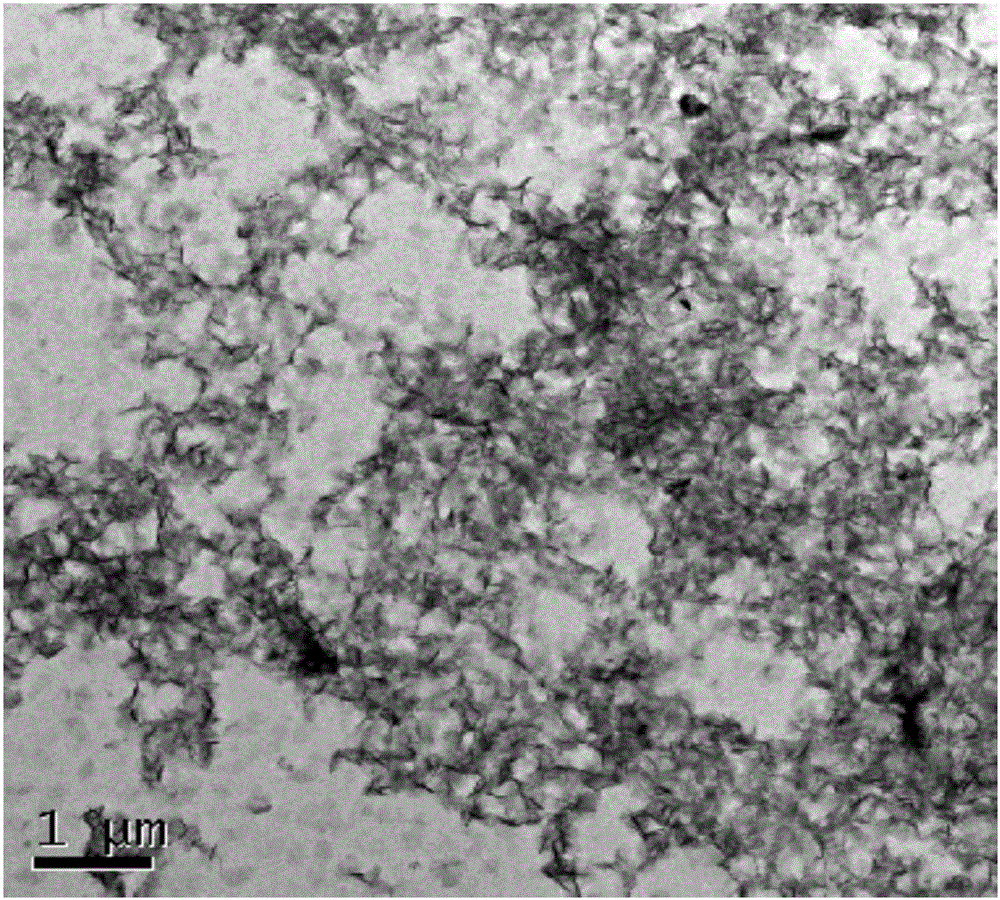

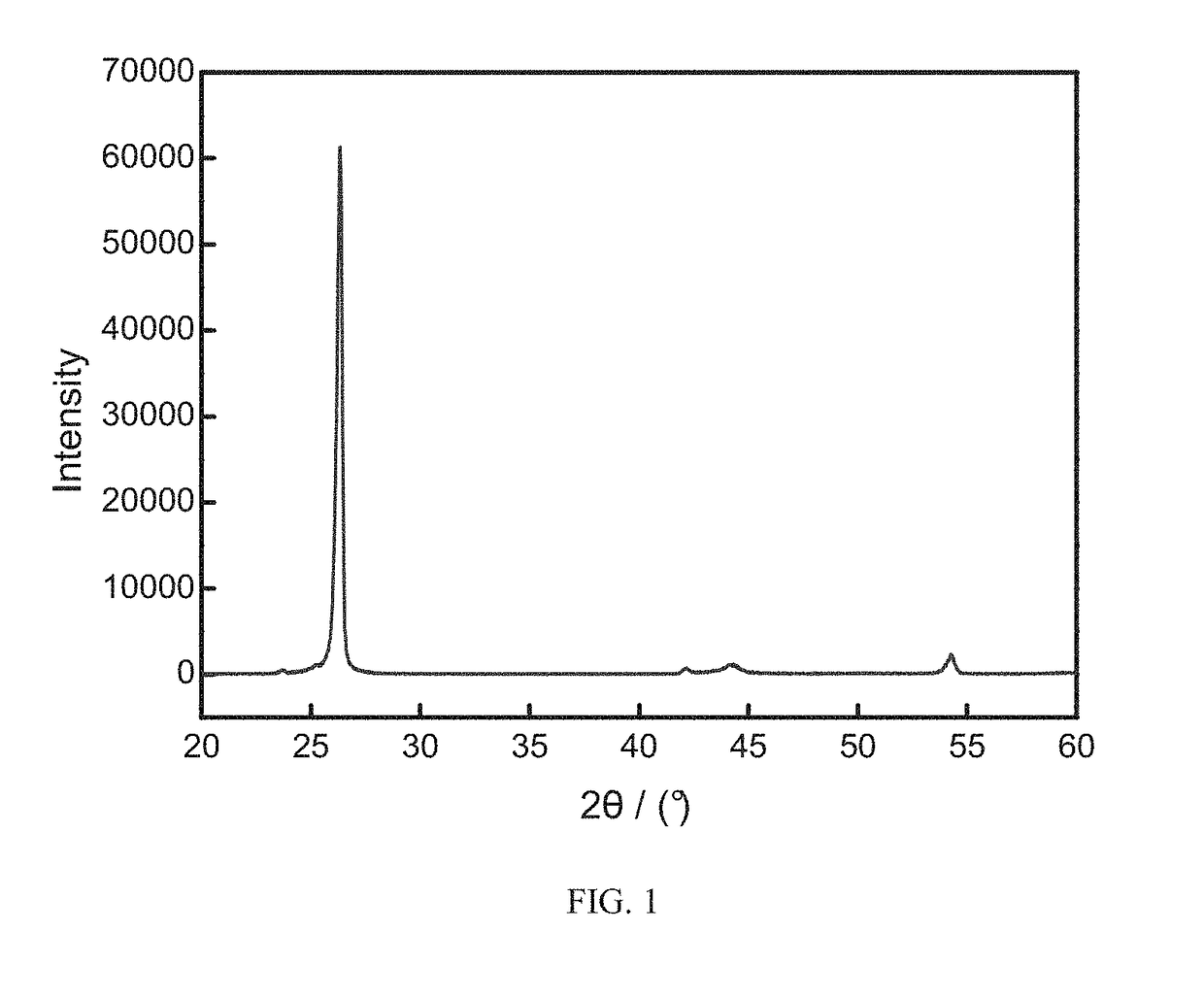

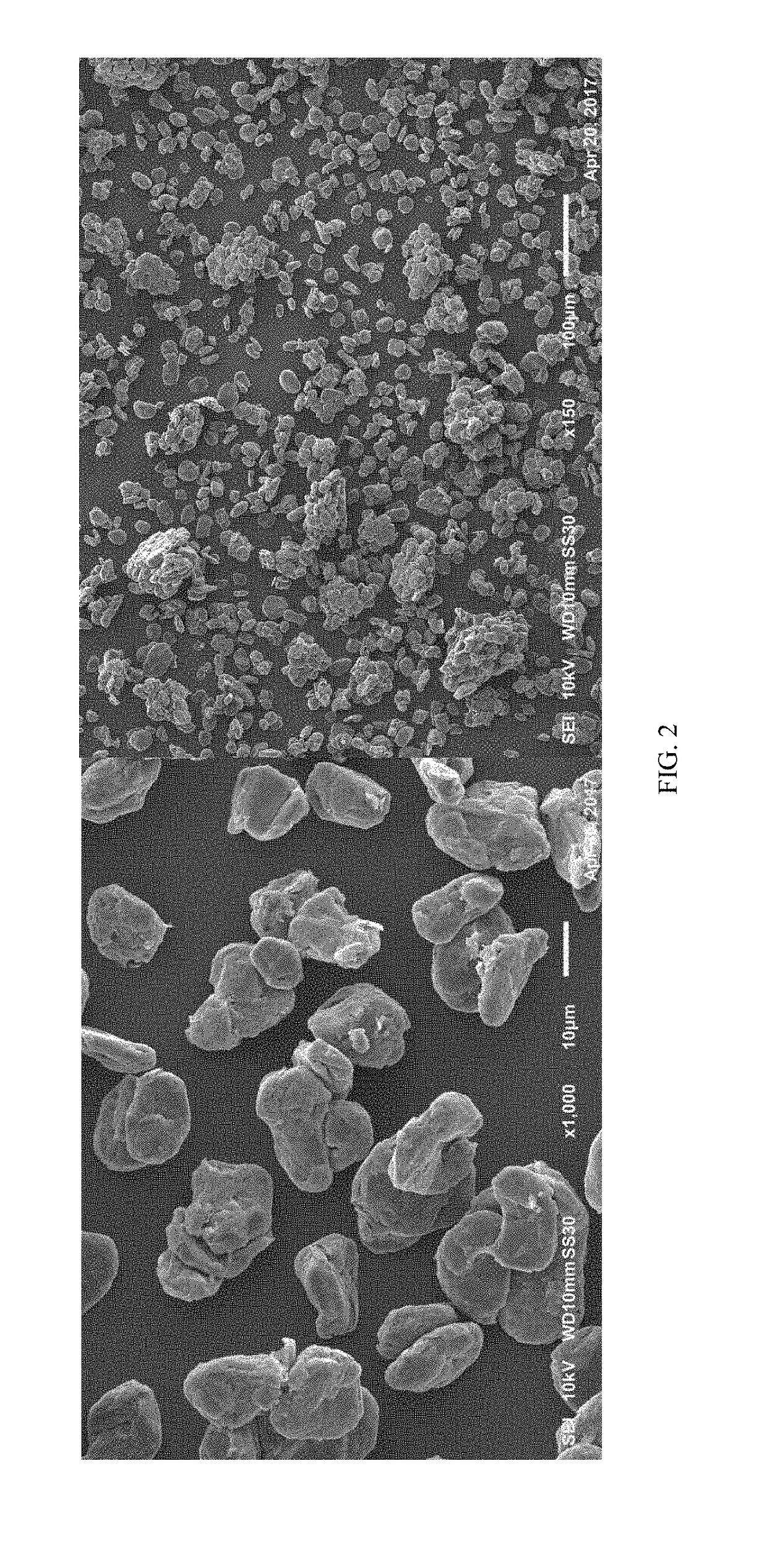

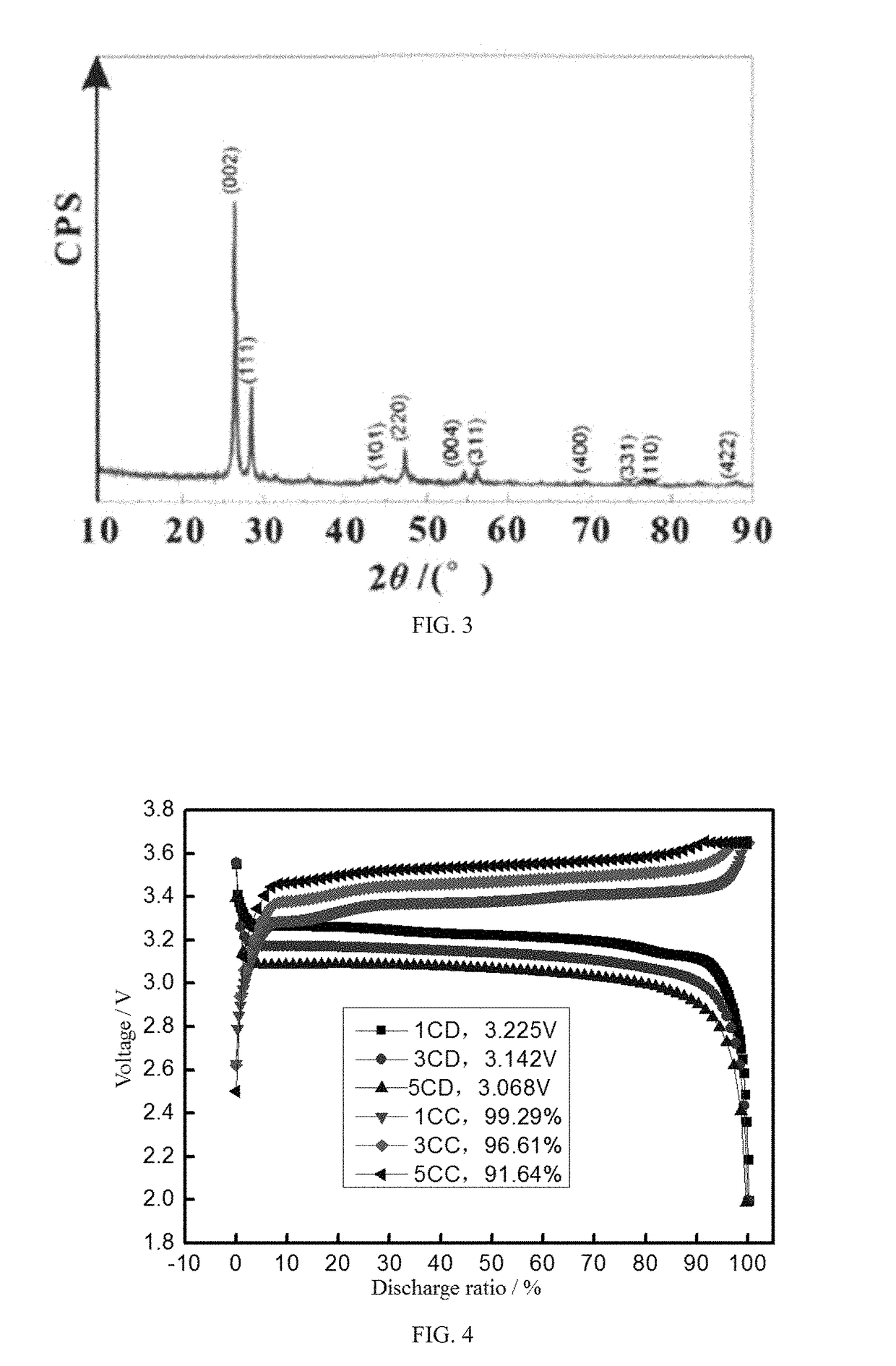

Preparation method of lithium ion battery composite negative electrode material

InactiveCN107706360AImprove conductivityIncreased ion mobilitySecondary cellsNegative electrodesDischarge efficiencyCarbonization

The invention provides a preparation method of a lithium ion battery composite negative electrode material. A nitrogen / sulfur-doped graphitized ordered mesoporous carbon material is prepared by takingpara toluene sulfonamide modified fatty acid as a carbon source, doping a nitrogen element and a sulfur element and performing high-temperature carbonization, annealing and strong alkali processing,the nitrogen / sulfur-doped graphitized ordered mesoporous carbon material is ordered and uniform in aperture, and lithium ion mobility and transmission in the material is facilitated; after nitrogen / sulfur doping, lone pair electrons on nitrogen atoms are used for improving the electron density and the electron conductivity of a battery material; by doping the sulfur element, the interface propertyof the carbon material is changed, and the compatibility and the wettability of the material and an electrolyte are improved; and after nanometer silicon powder is coated by the nitrogen / sulfur-dopedmesoporous graphite material, silicon is prevented from being in direct contact with the electrolyte, moreover, the huge volume expansion of the silicon during the charge-discharge process is effectively reduced, the structural stability of the material is maintained, an SEI membrane is prevented from being continuously generated, and the initial discharging efficiency is improved.

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

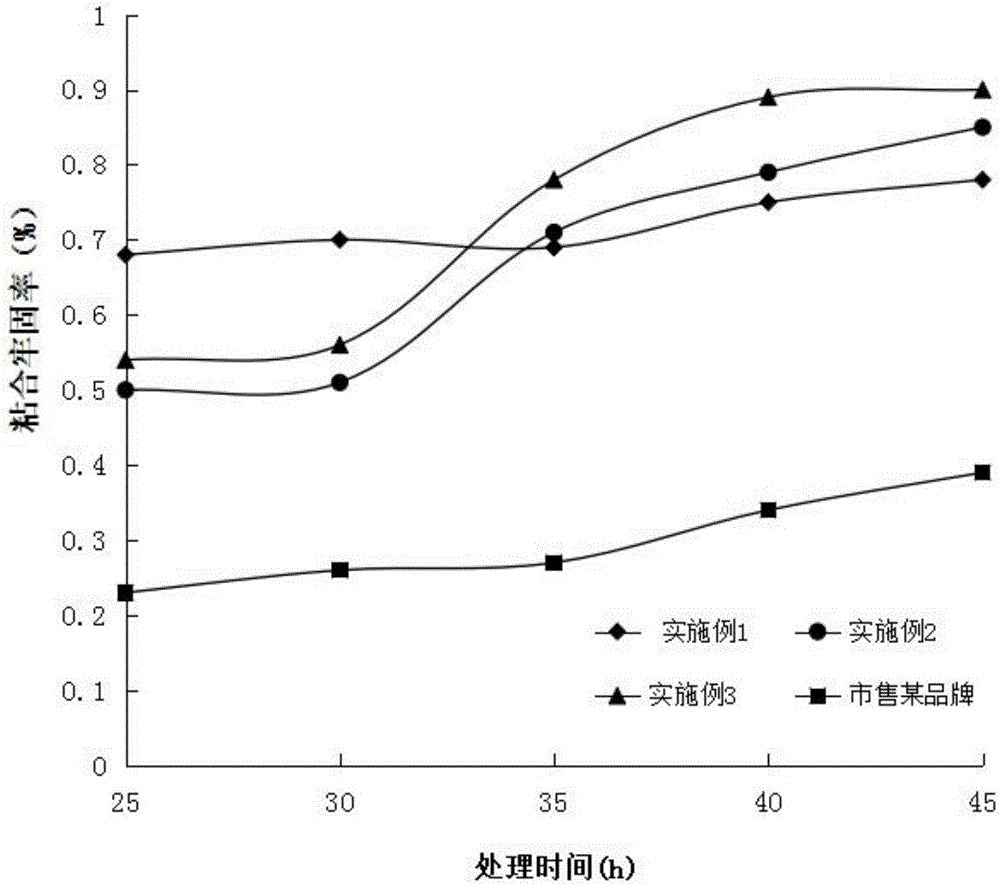

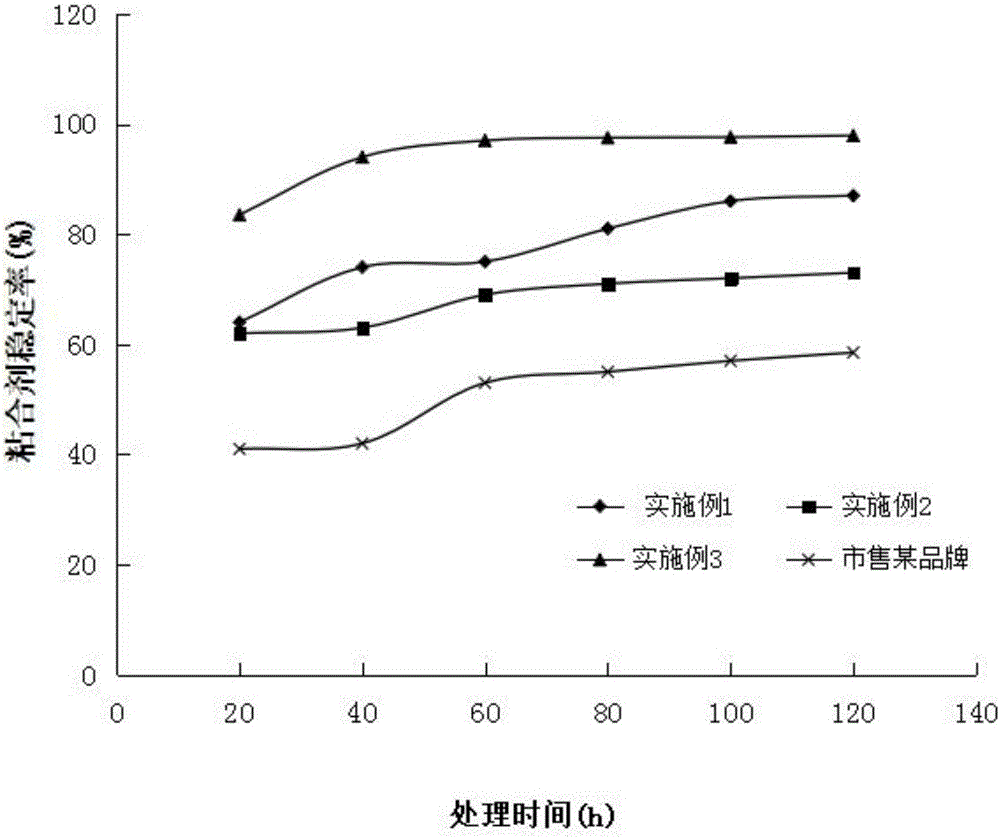

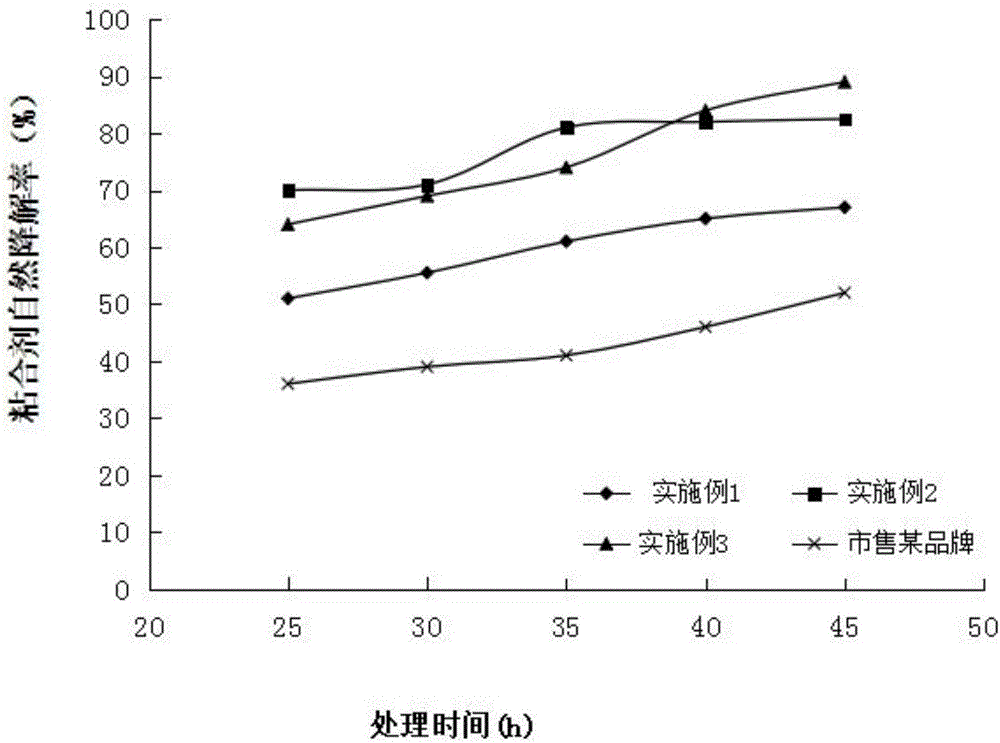

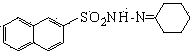

Preparation method and application of desulfurized fly ash energy-saving environmental-friendly building material adhesive

The invention discloses a preparation method and application of a desulfurized fly ash energy-saving environmental-friendly building material adhesive. The desulfurized fly ash energy-saving environmental-friendly building material adhesive consists of the following components in parts by weight: cation water, fatty alcohol polyethylene oxide ether sodium sulfate salt, succinic anhydride, N-cyclohexyl para toluene sulfonamide, N,N-dimethyl-p-nitrosoaniline, 1-amino-5-hydroxyl-4-[(1-methyl propyl] amino]-8-nitro-9,10-anthraquinone, 1-phenylamino-4-hydroxyanthraquinone, p-Methylthiobenzyl alcohol, gold nanoparticles, 4,4'-diamido-triphenylmethane, succinic anhydride, 4,4'-(3,3'-dichlorobiphenyl-4,4'-dinitrogen)di(4,5-dihydro-5-oxo-1-phenylpyrazole-3-formic acid) diethyl ester, benzotriazole-1-tri(trimethylamino)-trifluorophosphate, N-(2-benzimidazolyl) methyl carbamate and alpha-bromonaphthalene. The preparation method has the advantages that the adhesive is prevented from saponification, the surface tension of mixtures is reduced, and the mixtures can be relatively solidly adhered to one another; the adhesive has the advantages of stable chemical properties, wide application and high surface cleanliness ratios of molded structures.

Owner:XUZHOU UNIV OF TECH

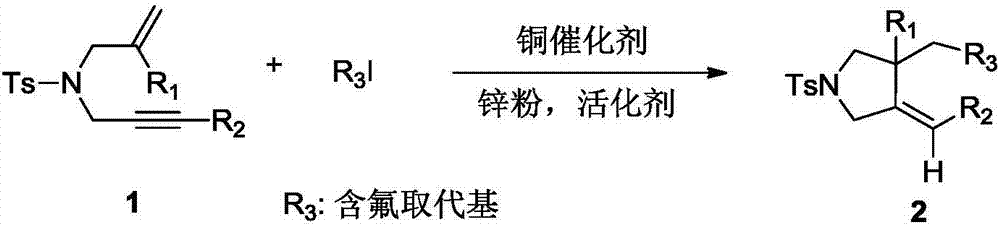

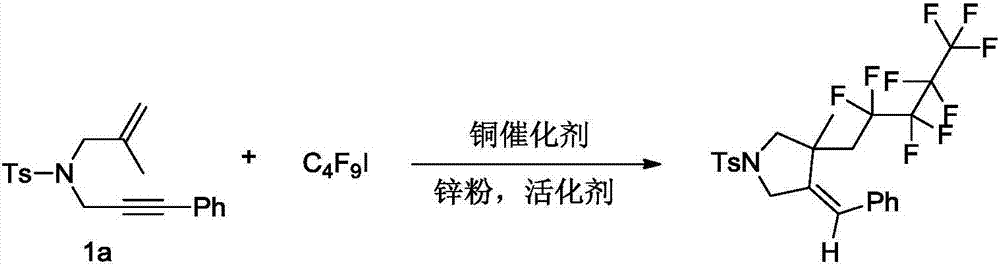

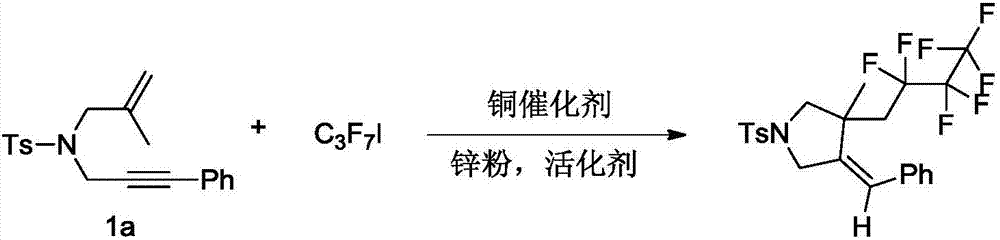

Preparation method of fluorine-containing polysubstituted pyrrolidine derivative

The invention discloses a preparation method of a fluorine-containing polysubstituted pyrrolidine derivative. The compound has the structure shown in the formula (I). The preparation method includes the following steps that in an inert gas environment, p-toluenesulfonamide-substitued 1,6-eneyne 1, fluorine-containing alkyl iodides, a copper catalyst, a reduction agent, an activating agent and a solvent are added in a reaction vessel, and reaction is conducted for 12-24 hours at 40-50 DEG C; after reaction is over, a rotary evaporator is used for evaporating the solvent through rotation, and acrude product is subjected to recrystallization or column chromatography to obtain the pyrrolidine derivative 2. The formula can be seen in the description.

Owner:JIANGNAN UNIV

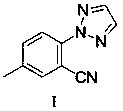

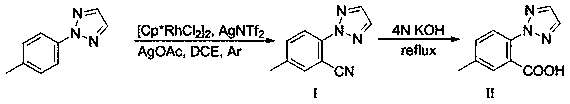

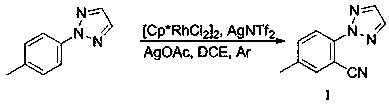

Method for synthesizing 5-methyl-2-(2H-1,2,3-triazole) benzoic acid

InactiveCN107674037AMild reaction conditionsImprove controllabilityOrganic chemistryBenzoic acidActivation method

The invention relates to synthesis of 5-methyl-2-(2H-1,2,3-triazole) benzoic acid and belongs to the field of organic chemistry. 2-(4-methyl phenyl)-2H-[1,2,3]-triazole serves as a raw material and undergoes tube sealing reaction at 150 DEG C for 48 h with N-cyano-N phenyl para toluene sulfonamide (NCTS) in an organic solvent in which a rhodium catalyst, a silver salt oxidizing agent and an acetate additive are added, and separation is performed, to obtain a compound I; the compound I undergoes heating reflux for 12 h in an alkaline solution, reaction liquid cools to room temperature and the pH is adjusted to 4-5, and a target compound II is obtained after extraction, drying and spin-drying. Compared with the prior art, a method for synthesis of 5-methyl-2-(2H-1,2,3-triazole) benzoic acidis simple to operate, the raw materials are economical, low in toxicity and high in yield; through one step in a C-H activation method, cyano groups are introduced at the second position of 2-(4-methyl phenyl)-2H-[1,2,3]-triazole benzene ring, and 5-methyl-2-(2H-1,2,3-triazole) benzoic acid is obtained by hydrolytic acidification. A reaction path is shortened, and the prepared product is high in purity, has no isomer and has a great application prospect.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane](https://images-eureka.patsnap.com/patent_img/08232ffb-774d-42f9-ae94-d68b0749a3a7/FDA0002150589320000011.png)

![Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane](https://images-eureka.patsnap.com/patent_img/08232ffb-774d-42f9-ae94-d68b0749a3a7/FDA0002150589320000012.png)

![Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane Asymmetric synthesis method for (S,S)-2,8-diazabicyclo[4,3,0]nonane](https://images-eureka.patsnap.com/patent_img/08232ffb-774d-42f9-ae94-d68b0749a3a7/FDA0002150589320000021.png)