Preparation method of electromagnetic shielding material based on carbon material, polypyrrole and alpha-iron sesquioxide

An electromagnetic shielding material and a technology of ferric oxide, which is applied in the field of preparation of electromagnetic shielding materials, can solve problems such as the performance disadvantage of electromagnetic shielding materials, and achieve the effects of good electromagnetic shielding performance, simple preparation method and reduction of secondary radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

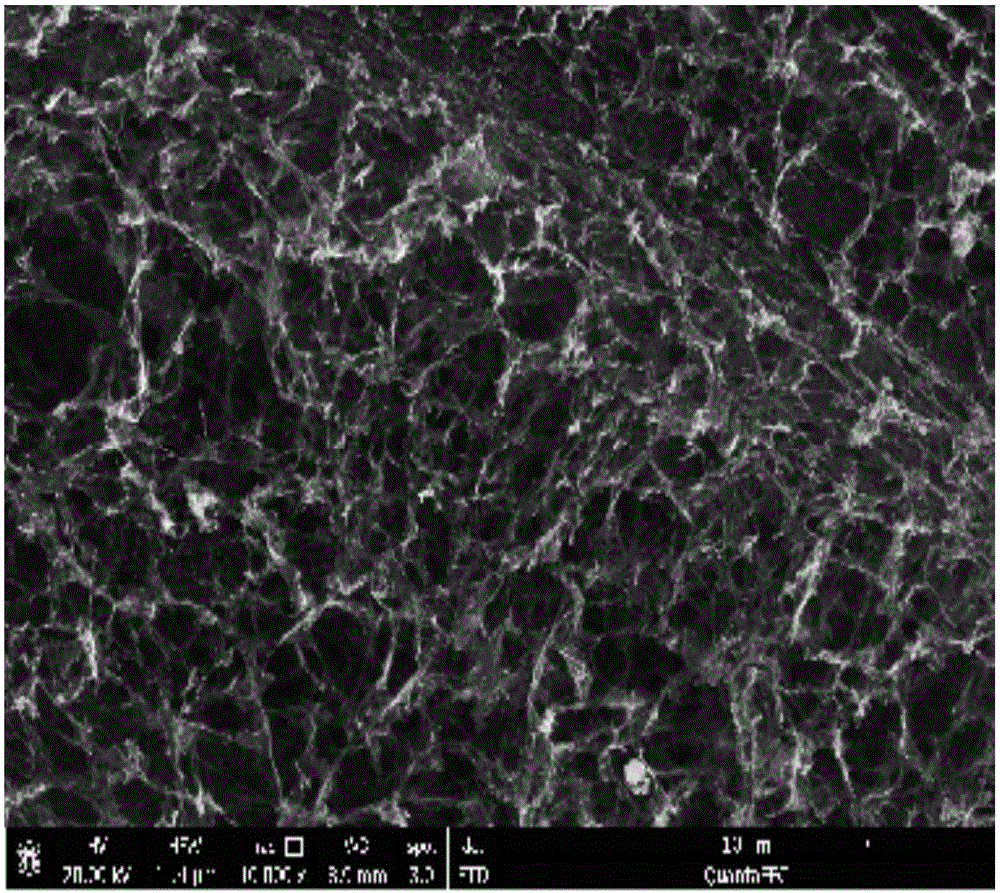

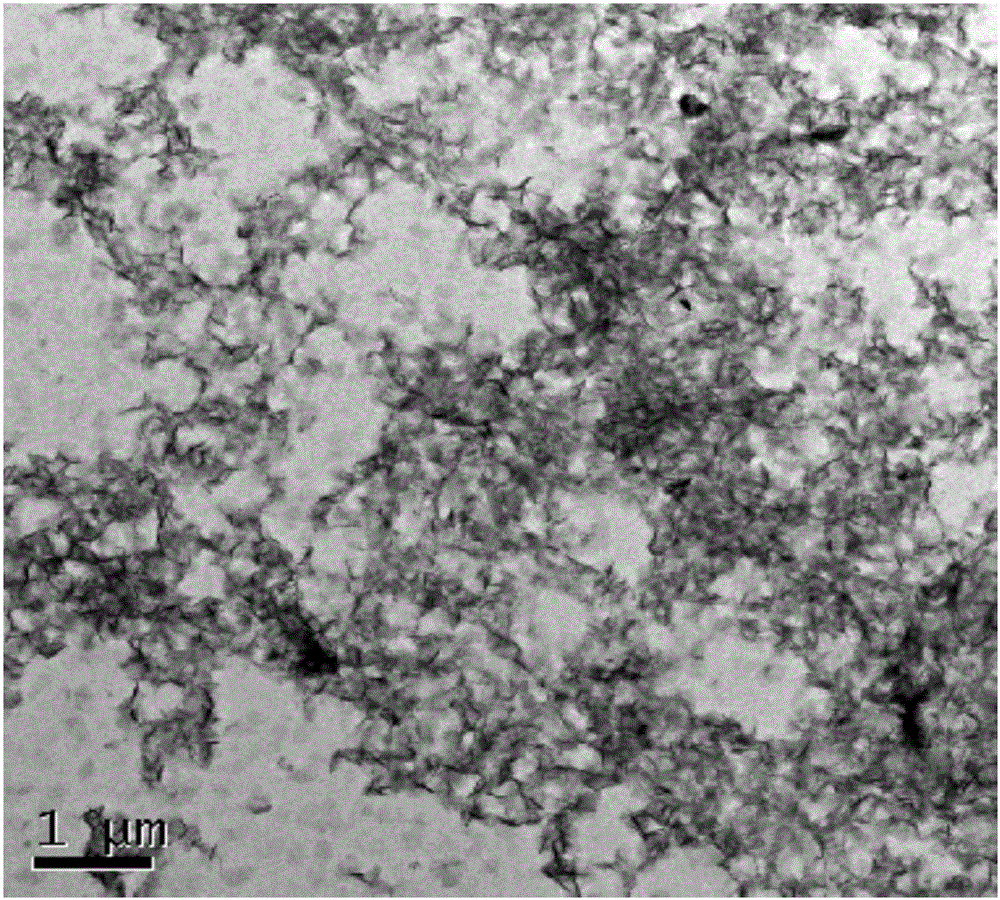

[0026] Embodiment 1: The preparation method of an electromagnetic shielding material based on three components of carbon material, polypyrrole and α-ferric oxide described in this embodiment is specifically carried out according to the following steps:

[0027] 1. Immersing the carbon material in concentrated nitric acid with a mass percentage of 65% for 0.1h to 100h to obtain the acid-treated carbon material;

[0028] The carbon material is carbon aerogel, carbon nanotube, graphene or carbon fiber;

[0029] The carbon airgel is prepared according to the following steps: the container containing the cellulose airgel is placed in a high-temperature pyrolysis device, and an inert gas is passed into the high-temperature pyrolysis device for 5 minutes to 20 minutes. Under protection, at a heating rate of 0.1°C / min to 20°C / min, the temperature of the high-temperature pyrolysis device is first raised to 200°C to 800°C, and kept at a temperature of 200°C to 800°C for 1h to 10h , and...

specific Embodiment approach 2

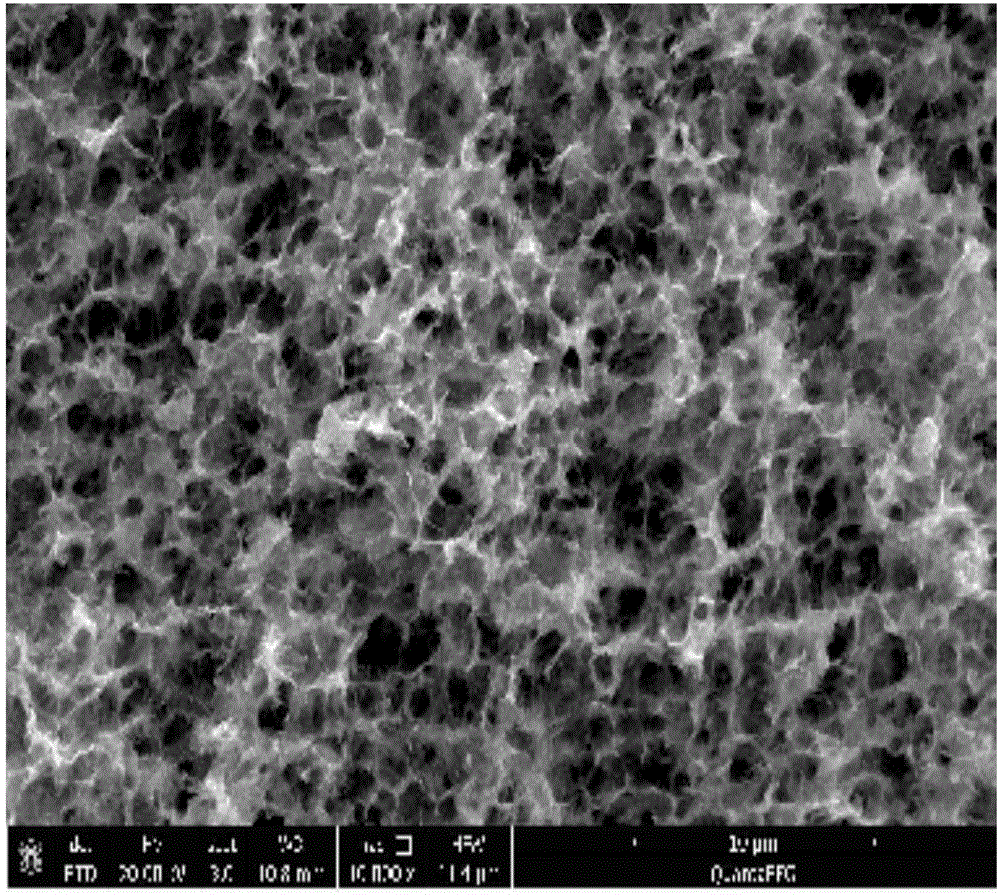

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carbon airgel described in step 1 is prepared according to the following steps: the cellulose airgel container is placed in a high-temperature pyrolysis device , into the high-temperature pyrolysis device into the inert gas for 10 minutes, under the protection of the inert gas, with a temperature increase rate of 5 ℃ / min, the temperature of the high-temperature pyrolysis device is first raised to 500 ℃, and the temperature is 500 ℃ heat preservation for 1 hour, then raise the temperature of the high-temperature pyrolysis device from 500 to 1000 degrees Celsius at a heating rate of 5 degrees Celsius / min, and keep the temperature at 1000 degrees Celsius for 2 hours, and then lower the temperature at a rate of 5 degrees Celsius / min, the temperature of the high-temperature pyrolysis device is lowered from 1000°C to 500°C, and after cooling down, the carbon airgel is obtained by natural cooli...

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the carbon material is immersed in concentrated nitric acid with a mass percentage of 65% for 24 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com