Preparation method of lithium ion battery composite negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems affecting electrode conductivity and cycle performance, electrode structure damage, and low Coulombic efficiency, etc., to improve battery rate performance and high cycle performance, electronic conductivity and ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

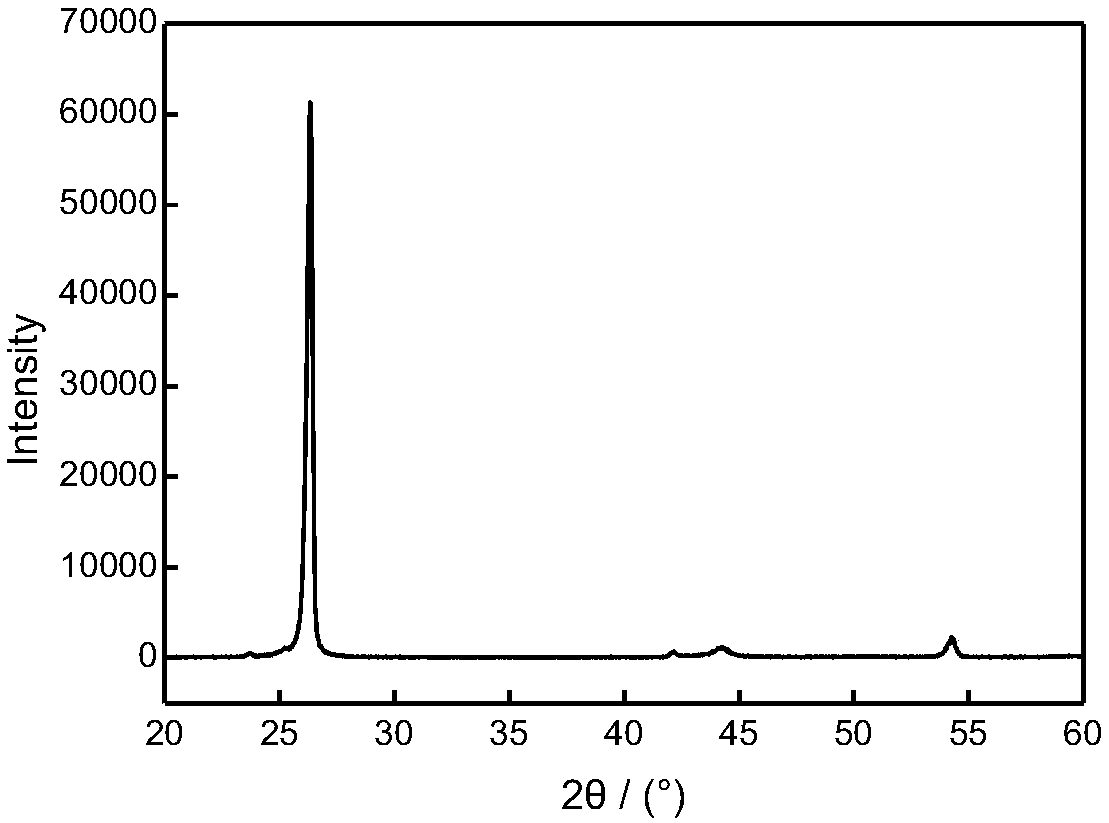

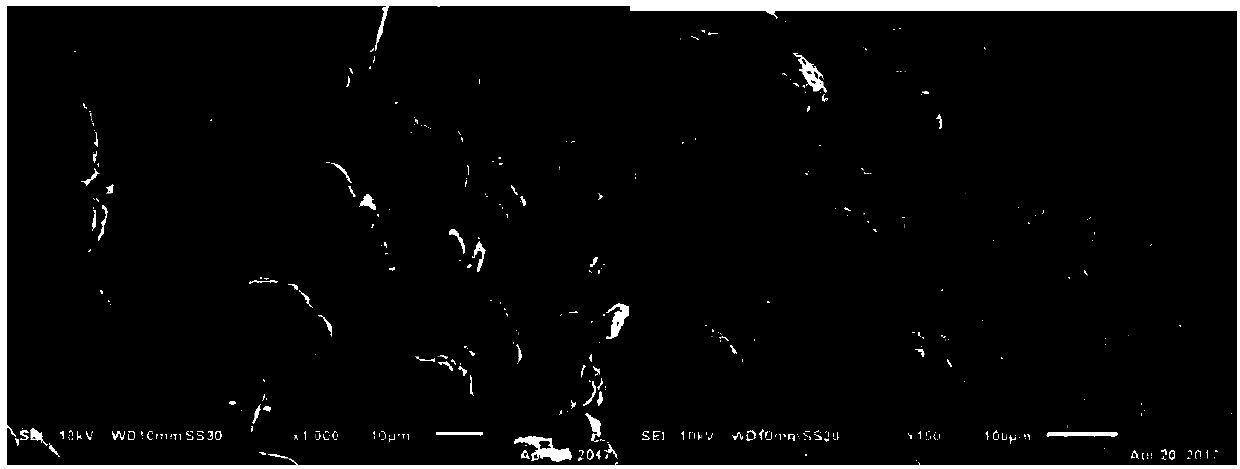

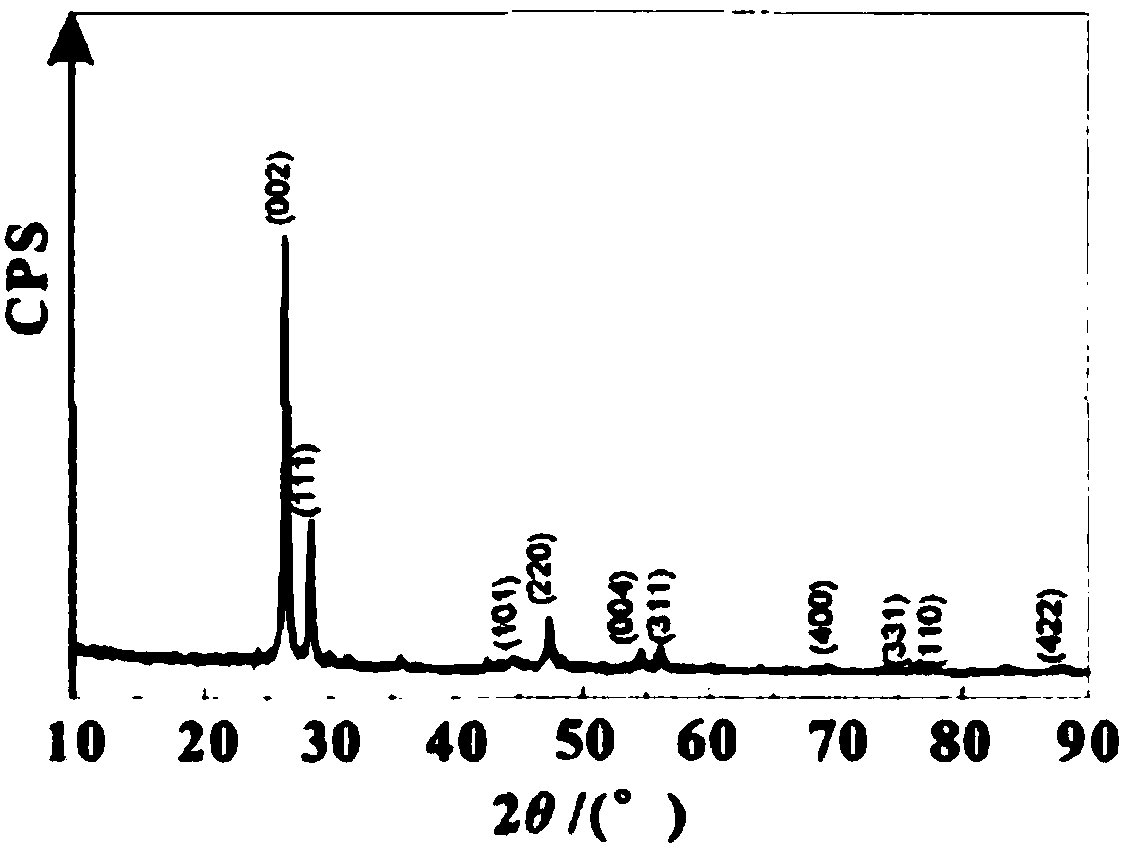

[0024] The invention provides a preparation method of a lithium-ion battery composite negative electrode material, comprising the following steps:

[0025] Step 1: Take a certain amount of fatty acid and dissolve it in absolute ethanol, take a certain amount of p-toluenesulfonamide and dissolve it in absolute ethanol, mix the two evenly, add a catalyst or condensing agent to react and then purify to obtain p-toluenesulfonate Amide-modified fatty acid solution;

[0026] Step 2: Add concentrated sulfuric acid dropwise to the p-toluenesulfonamide-modified fatty acid solution prepared in Step 1, and stir; then add template agent mesoporous silicon, stir for a period of time, and dry the mixture in an oven at 85-100°C After 1-2 hours to obtain solid powder, put the solid powder in a tube furnace, under the protection of nitrogen, calcinate at 200-300°C for 6-8 hours, then cool and take it out to prepare nitrogen / sulfur-doped mesoporous carbon material;

[0027] Step 3: The nitroge...

Embodiment 1

[0035] (1) Dissolve 8.0-9.0g oleic acid in absolute ethanol, dissolve 0.6-0.7g p-toluenesulfonamide in absolute ethanol, mix the two evenly in a round bottom flask, add catalyst or condensing agent to react After purification, the oleic acid solution modified by p-toluenesulfonamide is obtained;

[0036] (2) Add 0.5-0.8 g of concentrated sulfuric acid dropwise to the p-toluenesulfonamide-modified oleic acid solution prepared in (1), stir for 10-15 min, then add template agent mesoporous silicon, stir for a period of time, and place the mixed solution in Dry in an oven at 85-95°C for 1.0-1.5h to obtain solid powder, place the solid powder in a tube furnace, under the protection of nitrogen, calcinate at 200-260°C for 6.0-7.0h, cool and take it out to obtain nitrogen / sulfur Doped mesoporous carbon materials;

[0037] (3) The nitrogen / sulfur-doped mesoporous carbon material prepared in step 2 was heat-treated at 1000-1100°C for 4.0-4.5 hours under the protection of nitrogen gas,...

Embodiment 2

[0042] (1) Dissolve 8.0-9.5g palmitic acid in absolute ethanol, dissolve 0.6-0.8g p-toluenesulfonamide in absolute ethanol, mix the two evenly in a round bottom flask, add catalyst or condensing agent to react After purification, the palmitic acid solution modified by p-toluenesulfonamide is obtained;

[0043] (2) Add 0.5-0.7 g of concentrated sulfuric acid dropwise to the palmitic acid solution modified by p-toluenesulfonamide prepared in (1), stir for 10-15 min, then add template agent mesoporous silicon, stir for a period of time, and place the mixed solution in Dry in an oven at 85-95°C for 1.0-1.5h to obtain a solid powder, put the solid powder in a tube furnace, under the protection of nitrogen, calcinate at a high temperature of 200-300°C for 6-7 hours, then cool and take it out to obtain a nitrogen / sulfur doped Miscellaneous mesoporous carbon materials;

[0044] (3) The nitrogen / sulfur-doped mesoporous carbon material prepared in step 2 is heat-treated at 1000-1200°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com