Preparation method of fluorine-containing polysubstituted pyrrolidine derivative

A technology of fluorine-containing iodoalkane and pyrrolidine, which is applied in the field of preparation of fluorine-containing multi-substituted pyrrolidine derivatives, can solve the problems of many synthesis steps, high cost, and low yield, and achieve simple reaction operation and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

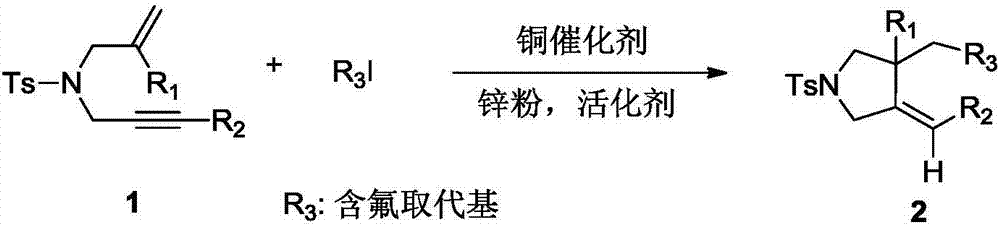

Method used

Image

Examples

Embodiment 1

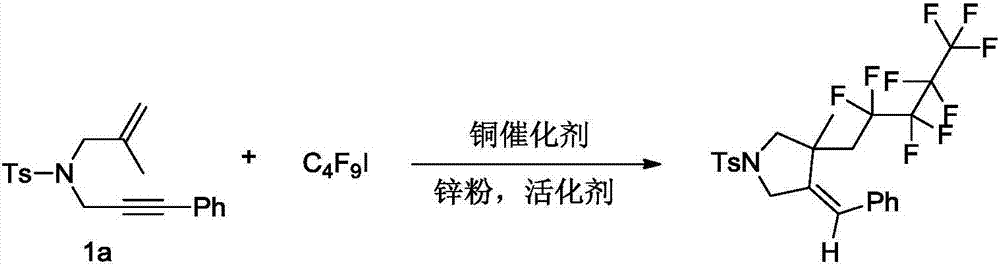

[0021] The preparation method of (E)-4-benzylidene-3-methyl-3-(2,2,3,3,4,4,5,5,5-nonafluoropentyl)-1-tosylpyrrolidine, its synthetic route is as follows:

[0022]

[0023] Embodiment one:

[0024] (E)-4-benzylidene-3-methyl-3-(2,2,3,3,4,4,5,5,5-nonafluoropentyl)-1-tosylpyrrolidine is prepared according to the following steps:

[0025] In an inert gas environment, add p-toluenesulfonamide enyne derivative 1a (1.0mmol, 339mg), perfluoroiodobutane (2.0mmol, 692mg), CuBr 2 (20%, 45mg), zinc powder (3.0mmol, 192mg), acetic acid (3.0mmol, 180mg), then add 10mL of dichloromethane, and react the reaction system in 40-50°C oil bath for 24 hours; The evaporator was rotated to remove the solvent, and the crude product was subjected to column chromatography to obtain 386 mg of fluorine-containing pyrrolidine compound, with a yield of 69%. The obtained compound has a melting point of 112-113.5°C, NMR 1 H NMR (400MHz, CDCl 3 ):7.74(d,J=8.0Hz,2H),7.38(d,J=8.0Hz,2H),7.25-7.27(m,3H),7.0...

Embodiment 2

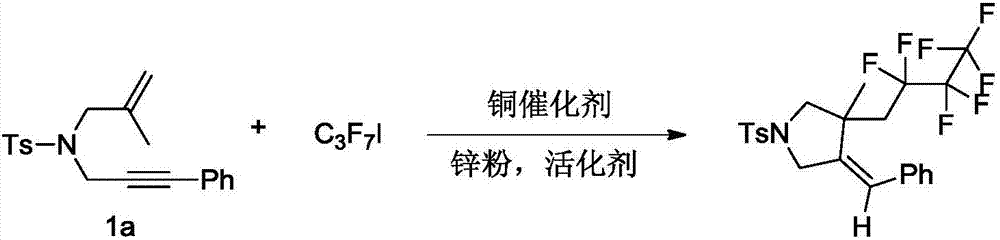

[0027] The preparation method of (E)-4-benzylidene-3-(2,2,3,3,4,4,4-heptafluorobutyl)-3-methyl-1-tosylpyrrolidine, its synthetic route is as follows:

[0028]

[0029] Embodiment two:

[0030] The preparation method of (E)-4-benzylidene-3-(2,2,3,3,4,4,4-heptafluorobutyl)-3-methyl-1-tosylpyrrolidine is carried out as follows:

[0031] In an inert gas environment, add p-toluenesulfonamide enyne derivative 1a (1.0mmol, 339mg), perfluoroiodopropane (2.0mmol, 592mg), CuBr 2 (20%, 45mg), zinc powder (3.0mmol, 192mg), acetic acid (3.0mmol, 180mg), then add 10mL of dichloromethane, and react the reaction system in 40-50°C oil bath for 24 hours; The evaporator was rotated to remove the solvent, and the crude product was subjected to column chromatography to obtain 356 mg of fluorine-containing pyrrolidine compound, with a yield of 70%. The obtained compound has a melting point of 94-95°C, NMR 1 H NMR (400MHz, CDCl 3 ):7.74(d,J=8.0Hz,2H),2.37(d,J=8.0Hz,2H),7.26-7.28(m,3H),7.08(d,...

Embodiment 3

[0033] (E)-3-methyl-3-(2,2,3,3,4,4,5,5,5-nonafluoropentyl)-4-(thiophen-2-ylmethylene)-1-tos ylpyrrolidine preparation method, Its synthetic route is as follows:

[0034]

[0035] Embodiment three:

[0036] (E)-3-methyl-3-(2,2,3,3,4,4,5,5,5-nonafluoropentyl)-4-(thiophen-2-ylmethylene)-1-tos ylpyrrolidine preparation method, Proceed as follows:

[0037] In an inert gas environment, add p-toluenesulfonamide enyne derivative 2a (1.0mmol, 345mg), perfluoroiodobutane (2.0mmol, 692mg), CuBr 2 (20%, 45mg), zinc powder (3.0mmol, 192mg), acetic acid (3.0mmol, 180mg), then add 10mL of dichloromethane, and react the reaction system in 40-50°C oil bath for 24 hours; The evaporator was rotated to remove the solvent, and the crude product was subjected to column chromatography to obtain 424 mg of fluorine-containing pyrrolidine compound with a yield of 75%. The resulting compound has a melting point of 100-102°C, and NMR 1 H NMR (400MHz, CDCl 3 ):7.73(d,J=8.0Hz,2H),7.38(d,J=8.0Hz,2H),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com