Preparation method for thymol

A technology of thymol and cresol, which is applied in the field of preparation of thymol, can solve the problems of laborious, time-consuming catalyst loading and replacement, long reaction time, etc., and achieve good economic and social benefits, less side reactions, and high selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

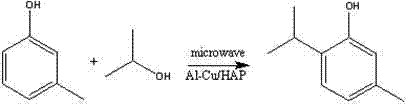

Image

Examples

Embodiment 1)

[0020] The preparation method of the thymol of the present embodiment is as follows:

[0021] Add 0.1 mol m-cresol and 0.1 mol isopropanol to a 50mL round-bottomed flask, stir well, then add 1g of Al-Cu / HAP catalyst to the mixture of m-cresol and isopropanol, stir again to obtain the reaction mass . The reaction materials were reacted for 5 min at a reaction temperature of 150° C. under microwave radiation with a power of 400 W to obtain 7.38 g of the target product thymol. The conversion rate of m-cresol is 50.36%, and the selectivity of the reaction is 97.57%.

[0022] The preparation method of the above-mentioned Al-Cu / HAP catalyst is as follows: 0.1 molAl(NO 3 ) 3· 9H 2 O, 0.01 mol CuSO 4· 5H 2 O was dissolved in 100mL of 0.05 mol / L dilute hydrochloric acid to obtain a mixed solution; 5 g of hydroxyapatite (HAP) as a carrier was added to the above mixed solution to obtain a solid-liquid mixture; 400mL of 1 mol / L NaOH solution was stirred evenly, and the above materi...

Embodiment 2)

[0024] The preparation method of the thymol of the present embodiment is as follows:

[0025] Add 0.1 mol m-cresol and 0.3 mol isopropanol to a 50mL round-bottomed flask, stir well, then add 1g of Al-Cu / HAP catalyst to the mixture of m-cresol and isopropanol, stir well again to obtain the reaction mass . The reaction materials were reacted for 5 min at a reaction temperature of 150° C. under microwave radiation with a power of 400 W to obtain 13.34 g of the target product thymol. The conversion rate of m-cresol is 91.48%, and the selectivity of the reaction is 97.12%.

[0026] The catalyst used in this example is the same as that in Example 1.

Embodiment 3)

[0028] All the other preparation methods of the thymol of the present embodiment are the same as in Example 1, except that the reaction material reacts for 10 min at a reaction temperature of 150° C. under microwave radiation of 400 W to obtain the target product Thymol Phenol 9.51g. The conversion rate of m-cresol is 65.34%, and the selectivity of the reaction is 96.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com