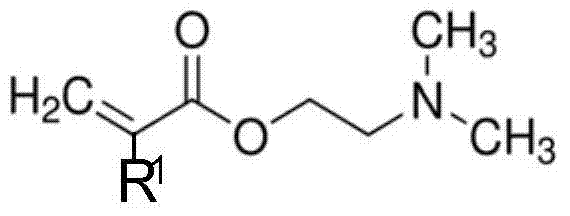

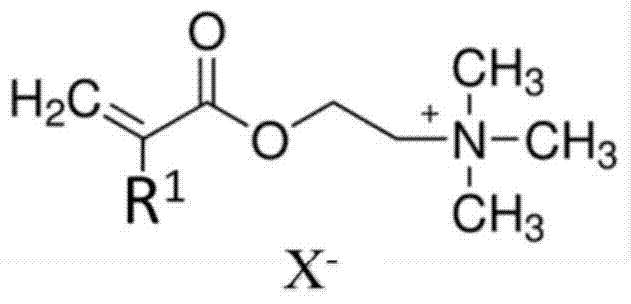

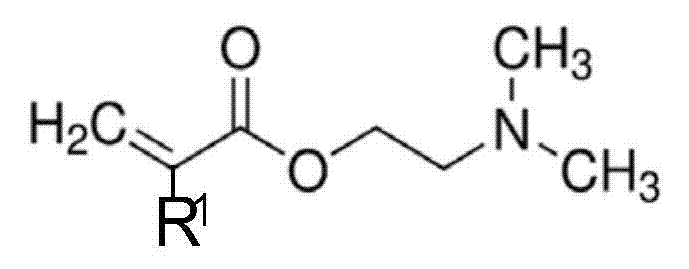

Preparation method of quaternary ammonium cationic monomer aqueous solution

A cationic monomer, aqueous solution technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve the problems of high price, reduce the hydrolysis of raw materials, stable production conditions, etc., and achieve maintenance and operation safety. Convenience, increased reaction rate and effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The tower reactor is an ordinary rectification tower with an electric heating belt attached to the tower body, the specification is 30×2.5mm, and the height is 1.5m. It is equipped with Φ2×2mm stainless steel θ ring packing, and the packing height is 1.3m. Heated by an electric heating belt to raise the temperature of the tower section to 45°C, and dimethylaminoethyl acrylate and water with a p-hydroxyanisole content of 0.06% were added to the static The mixer enters the reaction tower from the top feed port of the tower reactor after being fully mixed, and the methyl chloride gas enters the reaction tower from the bottom of the tower reactor at a feed rate of 2.3g / min. The product formed after the reaction mass was reacted in the reaction tower for 5 minutes was collected in a glass round bottom flask.

[0037]Analyze the content of dimethylaminoethyl acrylate in the crude product to calculate the conversion rate of raw materials, the conversion rate of dimethylaminoet...

Embodiment 2

[0039] The tower reactor is an ordinary rectification tower with an electric heating belt attached to the tower body, the specification is 30×2.5mm, and the height is 1.5m. It is equipped with Φ2×2mm stainless steel θ ring packing, and the packing height is 1.3m. Heated by an electric heating belt to raise the temperature of the tower section to 35°C, dimethylaminoethyl acrylate and water with a hydroquinone content of 0.15% were added to the static mixing at the feed rate of 9g / min and 3.2g / min respectively After being fully mixed, it enters the reaction tower from the top feed port of the tower reactor, and the methyl chloride gas enters the reaction tower from the bottom of the tower reactor at a feed rate of 3.5g / min. The product formed after the reaction mass was reacted in the reaction tower for 4 minutes was collected in a glass round bottom flask.

[0040] Analyze the content of dimethylaminoethyl acrylate in the crude product to calculate the conversion rate of raw ma...

Embodiment 3

[0042] The tower reactor is an ordinary rectification tower with an electric heating belt attached to the tower body, the specification is 30×2.5mm, and the height is 1.5m. It is equipped with Φ2×2mm stainless steel θ ring packing, and the packing height is 1.3m. Heated by an electric heating belt to raise the temperature of the tower section to 55°C, and dimethylaminoethyl methacrylate with a hydroquinone content of 0.1% and water were added at the same time at a feed rate of 6g / min and 2.0g / min respectively The static mixer enters the reaction tower from the top feed port of the tower reactor after being fully mixed, and the methyl chloride gas enters the reaction tower from the bottom of the tower reactor at a feed rate of 2.1 g / min. The product formed after the reaction mass was reacted in the reaction tower for 8 minutes was collected in a glass round bottom flask.

[0043] Analyze the content of dimethylaminoethyl methacrylate in the crude product in the flask to calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com