Low/high-heat-resistant ABS resin and preparation method thereof

An ABS resin, heat-resistant technology, applied in the field of preparation of modified ABS resin, can solve the problems of not meeting the application requirements of heat-resistant ABS resin, unsatisfactory thermal deformation temperature, and reduced impact strength, and achieves outstanding heat-resistant effect and fluidity. The effect of better sexuality and maintenance of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

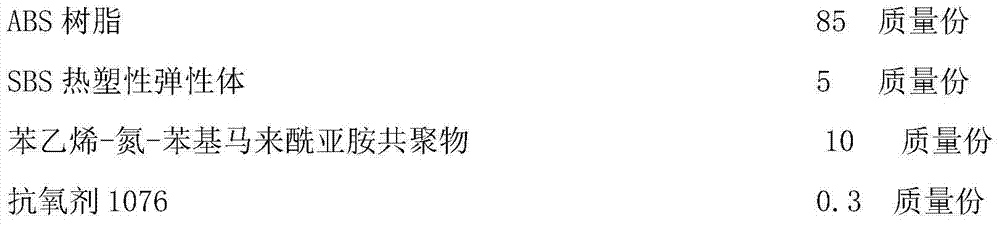

Embodiment 1

[0023] (1) Process formula

[0024]

[0025] (2) Processing technology

[0026] Mix 85 parts by mass of ABS resin, 5 parts by mass of SBS thermoplastic elastomer, 10 parts by mass of styrene-nitrogen-phenylmaleimide copolymer, and 0.3 parts by mass of antioxidant in a high-speed mixer at 80-90°C 5 minutes, and then extrude and granulate on the twin-screw extruder. The temperature of the extruder is: 220°C for the first interval, 225°C for the second and third intervals, 230°C for the fourth, fifth, sixth, seventh, and eighth intervals, and 225°C for the ninth interval. ℃, extruded and made into strips, according to GB / T9341-2000 to test bending properties, GB / T1843-1996 to test impact properties, GB1040-92 to test tensile properties, GB / T3682-2000 to test melt flow rate, GB / T1633-2000 test heat distortion temperature.

[0027] According to this process, high heat-resistant ABS resin is obtained. Its performance is shown in Table 3.

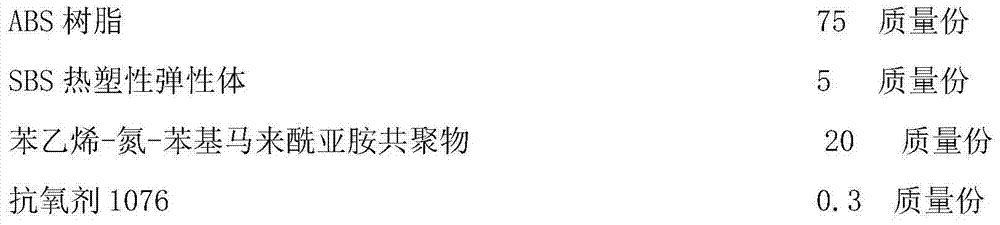

Embodiment 2

[0029] Process recipe

[0030]

[0031] The above formula is molded according to the processing technology of Example 1 to obtain high heat-resistant ABS resin. Its performance is shown in Table 1, 2, 3.

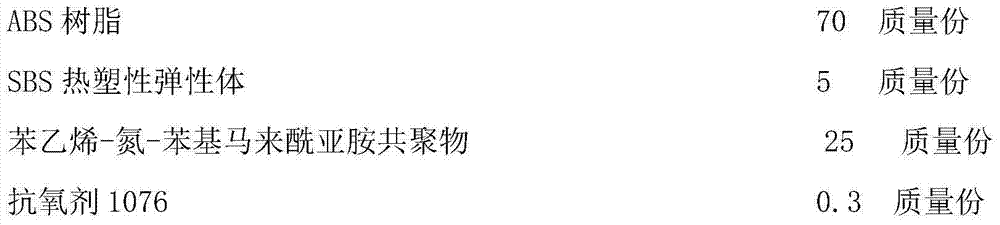

Embodiment 3

[0033] Process recipe

[0034]

[0035] The above formula is molded according to the processing technology of Example 1 to obtain high heat-resistant ABS resin. Its performance is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com