High-activity compound modified additive of methanol gasoline for automobile and preparation process thereof

A methanol gasoline, compound modification technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve problems such as wear and tear miscibility, abnormal emission of methanol combustion, and corrosion of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

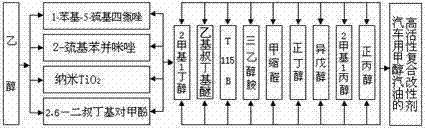

Method used

Image

Examples

Embodiment 1

[0035] Will 12% ethanol as solvent; 2-methyl-1-butanol 0.1% as antiknock agent; Sulfurized calcium alkylphenate 0.5% as regulator; Triethanolamine 1.5% is used as an engine carbon deposit preventer and anticorrosion agent; Methylal 2.5% as a combustion aid; 59% n-butanol as an active mutual solvent; 0.1% of 3-methyl-1-butanol is used as a synthesis solvent; 2-methyl-1-propanol 10% as a synthetic solvent; 10% n-propanol as a synthetic solvent; Ethyl tert-butyl ether 0.1% as antiknock agent, put 1-phenyl-5-mercapto-tetrazolium content 2% as anti-corrosion agent, 2-Mercaptobenzimidazole content 1% as anti-corrosion agent and Nano-TiO? content of 0.6% as a sealing agent, 2.6-di-tert-butyl-p-cresol content of 0.6% is used as an antioxidant, and it is a highly active composite modified additive for methanol gasoline for automobiles after compounding.

Embodiment 2

[0037] Will 12% ethanol as solvent; 2-methyl-1-butanol 0.1% as antiknock agent; Sulfurized calcium alkylphenate 0.5% as regulator; Triethanolamine 1.5% is used as an engine carbon deposit preventer and anticorrosion agent; Methylal 2.5% as a combustion aid; 59.6% n-butanol as an active mutual solvent; 0.1% of 3-methyl-1-butanol is used as a synthesis solvent; 2-methyl-1-propanol 10% as a synthetic solvent; 10% n-propanol as a synthetic solvent; Ethyl tert-butyl ether 0.1% as antiknock agent, put 1-phenyl-5-mercapto-tetrazolium content 2% as anti-corrosion agent, 2-Mercaptobenzimidazole content 1% as anti-corrosion agent and Nano-TiO? content of 0.6% is used as a sealing agent, and it is compounded into a highly active compound modified additive for methanol gasoline for automobiles.

Embodiment 3

[0039] Will 12% ethanol as solvent; 2-methyl-1-butanol 0.1% as antiknock agent; Sulfurized calcium alkylphenate 0.5% as regulator; Triethanolamine 1.5% is used as an engine carbon deposit preventer and anticorrosion agent; Methylal 2.5% as a combustion aid; 60.2% n-butanol as an active mutual solvent; 0.1% of 3-methyl-1-butanol is used as a synthesis solvent; 2-methyl-1-propanol 10% as a synthetic solvent; 10% n-propanol as a synthetic solvent; Ethyl tert-butyl ether 0.1% as antiknock agent, put 1-phenyl-5-mercapto-tetrazolium content 2% as anti-corrosion agent and 2-Mercaptobenzimidazole content 1% is used as an anti-corrosion agent, and is a highly active compound modified additive for methanol gasoline for automobiles after compounding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com