A kind of control method of camellia seed moisture

A control method and technology for camellia seeds, which are applied in the production of edible oil/fat, tallow oil/fat, and fat production, can solve the problems of increased acid value and peroxide value, increased benzopyrene content of tea seed oil, etc. The effect of low oxidation value, strong aroma and high food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

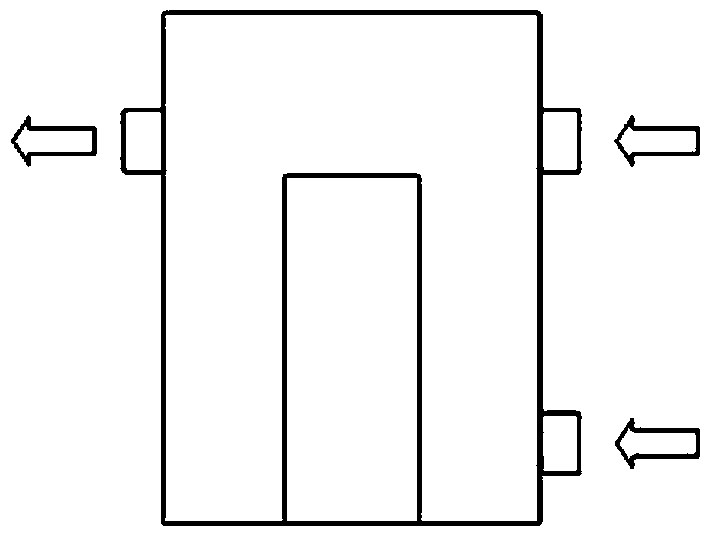

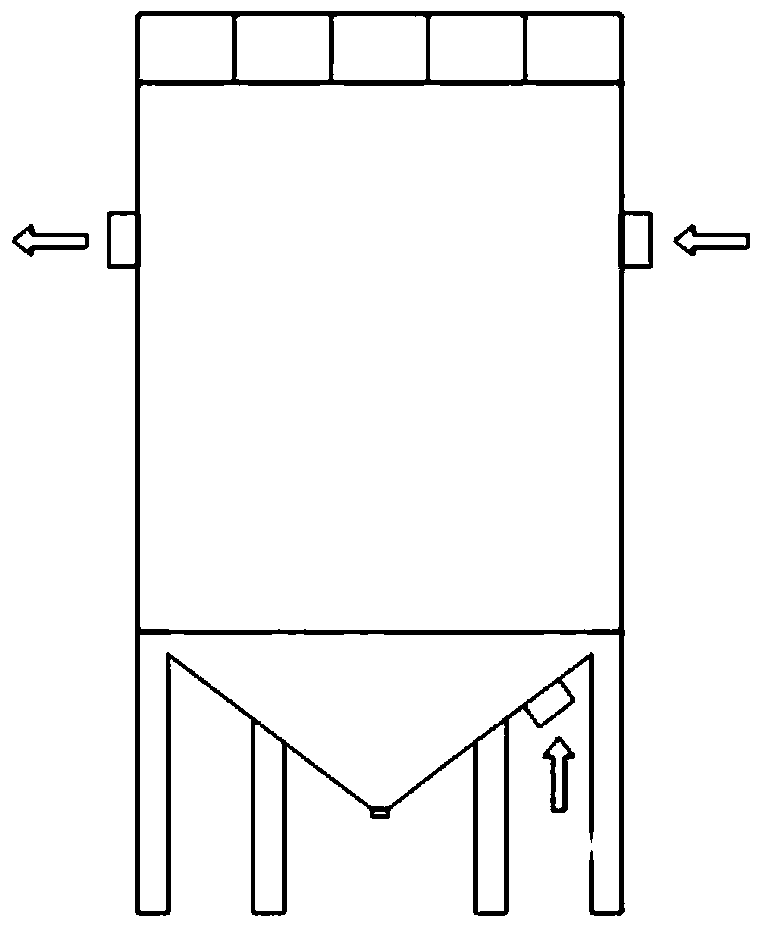

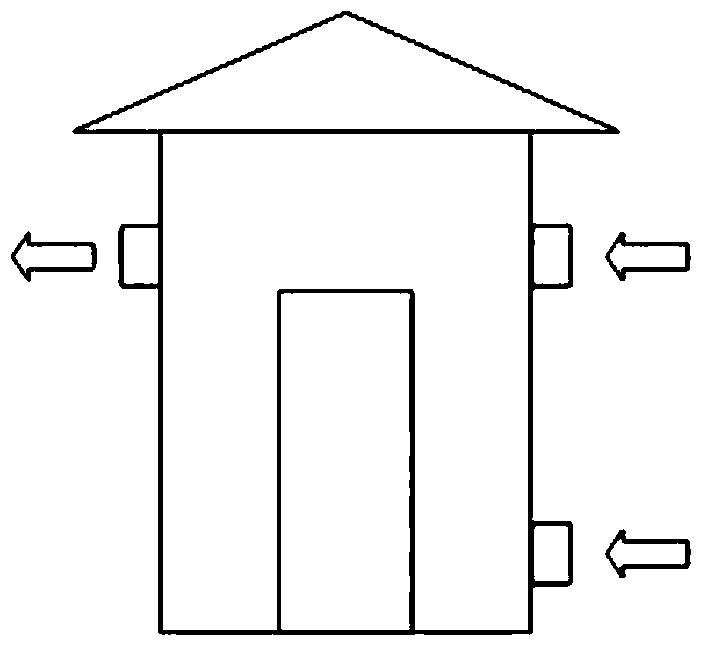

Image

Examples

Embodiment 1

[0021] (1) 500 kg of Camellia oleifera seeds were removed from the exocarp and impurity-removed and graded in a well-closed warehouse with improved airtightness, and the storage time was 24 hours;

[0022] (2) Supply hot air at a temperature of 42°C to the modified airtight warehouse during the storage process to ensure that the warehouse temperature is at 32°C during the storage process;

[0023] (3) Put the Camellia oleifera seeds stored out of the warehouse in a mixer with a heating device, a stirring device and a spray head, heat to 50° C. and keep stirring for 5 hours. During the heating process, the temperature at which 2% of the total mass of the tea seeds is sprayed is 50℃ hot water;

[0024] After balance, the moisture content of Camellia oleifera seeds was 9.5%, and the difference between the highest and lowest moisture content of 30 sampling points was 0.12%, and the difference before balance was 1.8%.

Embodiment 2

[0026] (1) store 500kg of Camellia oleifera seeds that remove the exocarp and remove impurities and classify with a modified well-sealed silo, and the storage time is 36h;

[0027] (2) Supply hot air at a temperature of 40°C to the modified airtight warehouse during the storage process to ensure that the warehouse temperature is at 31°C during the storage process;

[0028] (3) Put the Camellia oleifera seeds stored out of the warehouse in a mixer with a heating device, a stirring device and a spray head, heat to 45°C and keep stirring for 4 hours. During the heating process, the temperature of 1.5% of the total mass of the tea seeds is properly sprayed 45 ℃ hot water;

[0029] After balance, the moisture content of Camellia oleifera seeds was 8.2%, and the difference between the highest and lowest moisture content of 30 sampling points was 0.1%, and the difference before balance was 1.7%.

Embodiment 3

[0031] (1) store 500kg of Camellia oleifera seeds with removed exocarp and impurity-removed grades in a large container with improved airtightness, and the storage time is 48h;

[0032] (2) During the storage process, supply hot air with a temperature of 37°C to the modified airtight chamber to ensure that the warehouse temperature is at 30°C during the storage process;

[0033] (3) Put the camellia seeds stored out of the warehouse in a mixer with a heating device, a stirring device and a spray head, heat to 40°C and keep stirring for 3 hours. During the heating process, the temperature at which 1% of the total mass of the tea seeds is sprayed is 40°C hot water;

[0034] After balance, the moisture content of Camellia oleifera seeds was 7.2%, and the difference between the highest and lowest moisture content of 30 sampling points was 0.05%, and the difference before balance was 1.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com