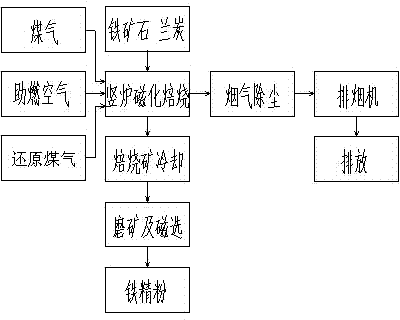

Refractory low-grade iron ore shaft furnace semi-coke added magnetizing roast process

A magnetized roasting and iron ore technology, which is applied in the field of metallurgy and mineral engineering, can solve the problems of lagging and leading, low calorific value, and low quality of output products, so as to reduce the amount of reducing gas, increase the concentration of reducing medium, and improve metal recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below figure 1 , at 100m 3 Taking a small shaft furnace and using gas heating as an example, a further detailed description is given of a shaft furnace for refractory low-grade iron ore with garland charcoal magnetization roasting.

[0028] 1. Selection of materials

[0029] Refractory low-grade iron ore: the ore type is specularite (composed of hematite, limonite and siderite), the particle size is 15-50mm, and the iron grade is 31-35%;

[0030] Semi-coke: fixed carbon content is 72-76%, ash content is 11-15%, volatile content is 10-14%, particle size is 15-30mm;

[0031] Coal gas for heating and reduction: high-coke mixed gas.

[0032] 2. Preheating of iron ore

[0033] Mix iron ore with a particle size of 15-50mm and semi-coke with a particle size of 15-30mm in a mass ratio of 100:2-5, mix evenly and add from the top of the shaft furnace, and the iron ore depends on its own gravity from top to bottom Flowing downward, heat exchange is performed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com