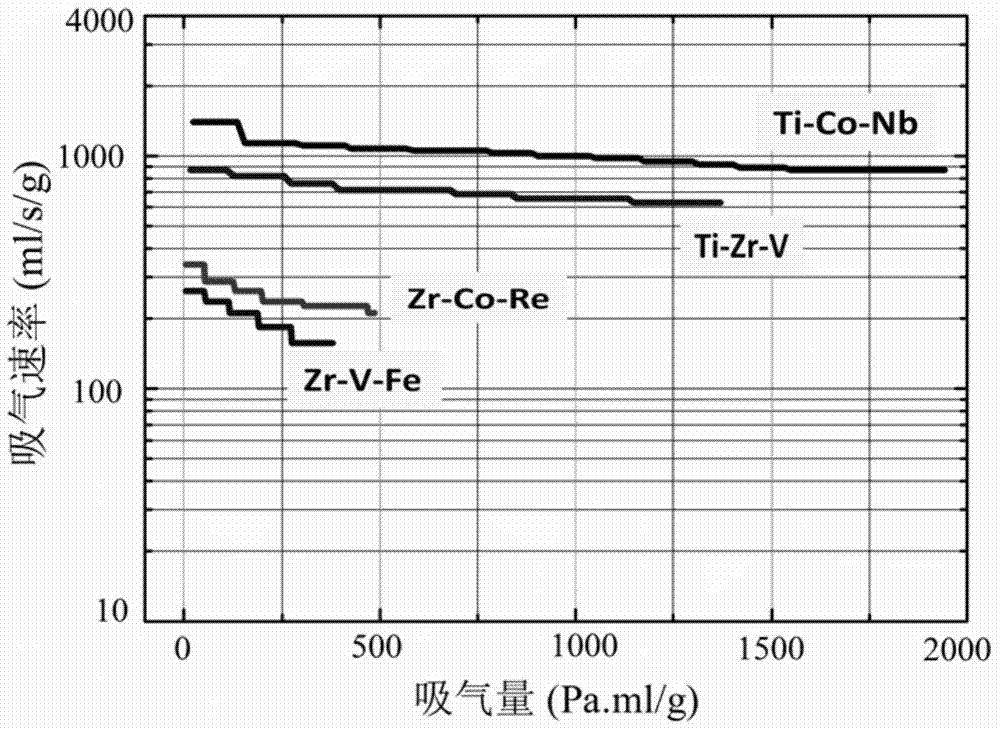

Non-evapotranspire type low-temperature activated titanium-based getter alloy and preparation method thereof

A getter and non-evaporable technology, which is applied in the field of non-evaporable low-temperature activated titanium-based getter alloy and its preparation, to achieve the effects of improved getter performance, strong binding force, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Metal element materials were weighed according to the following mass percentages: titanium: 76%, cobalt: 18.5%, niobium: 5.5%, and unavoidable impurities accounted for 0.2% of the total.

[0022] Getter alloy manufacturing process: put the above-mentioned titanium and cobalt metal elements into the graphite crucible of the intermediate frequency vacuum melting furnace, when the vacuum degree is 1×10 -1 Pa, start heating and melting, and the melting temperature is 1750°C. When the material is completely melted into a liquid state, it is poured into the cooling mold, and taken out from the furnace body after being completely cooled, it is a titanium-cobalt getter alloy ingot. Then it is broken into granules smaller than 20mm square, put into the ball mill, under the state of protective gas, the ball is milled into powder, and filtered with a sieve to ensure that the diameter of the powder is 30 microns, and then mixed with niobium powder with a particle size of 35 microns...

Embodiment 2

[0025] Metal element materials are weighed according to the following mass percentages: titanium: 78%, cobalt: 18%, niobium: 4%, and unavoidable impurities account for 0.3% of the total;

[0026] Getter alloy manufacturing process: put the above-mentioned titanium and cobalt metal elements into the graphite crucible of the intermediate frequency vacuum melting furnace, when the vacuum degree is 1×10 -1 Pa, start heating and melting, the melting temperature is 1850°C. When the material is completely melted into a liquid state, it is poured into the cooling mold, and taken out from the furnace body after being completely cooled, it is a titanium-cobalt getter alloy ingot. Then crush it into granules smaller than 15mm square, put it into a ball mill, and in the state of protective gas, ball mill it into powder, filter it with a sieve to ensure that the diameter of the powder is 35 microns, and then mix it with niobium powder with a particle size of 30 microns according to the pro...

Embodiment 3

[0029] Metal element materials are weighed according to the following mass percentages: titanium: 77%, cobalt: 17.5%, niobium: 5.5%, and unavoidable impurities account for 0.1% of the total;

[0030] Getter alloy manufacturing process: put the above-mentioned titanium and cobalt metal elements into the graphite crucible of the intermediate frequency vacuum melting furnace, when the vacuum degree is 5×10 -2 Pa, start heating and melting, and the melting temperature is 1800°C. When the material is completely melted into a liquid state, it is poured into the cooling mold, and taken out from the furnace body after being completely cooled, it is a titanium-cobalt getter alloy ingot. Then crush it into granules smaller than 18mm square, put it into a ball mill, and in the state of protective gas, ball mill it into powder, filter it with a sieve to ensure that the diameter of the powder is 40 microns, and then mix it with niobium powder with a particle size of 45 microns according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com