High-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy and preparation method thereof

An ultra-high-strength, heat-resistant alloy technology, applied in the field of high-density kinetic energy ultra-high-strength tungsten-nickel heat-resistant alloy and its preparation, can solve the problems of uneven deformation, low service temperature, and poor toughness, and achieve organizational consistency and The effect of good uniformity, high strength and impact toughness, and good dynamic strength

Active Publication Date: 2015-07-01

CENT IRON & STEEL RES INST

View PDF7 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

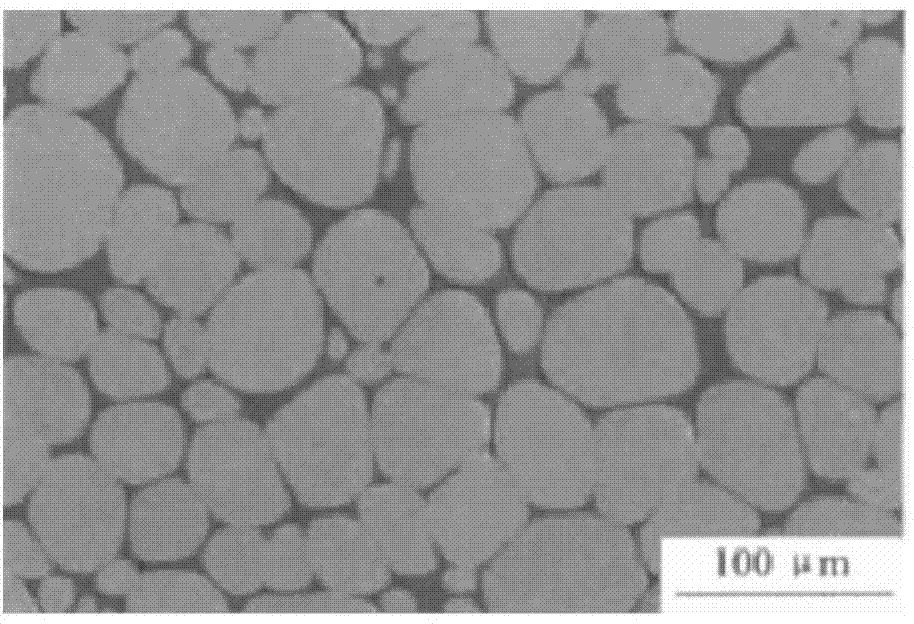

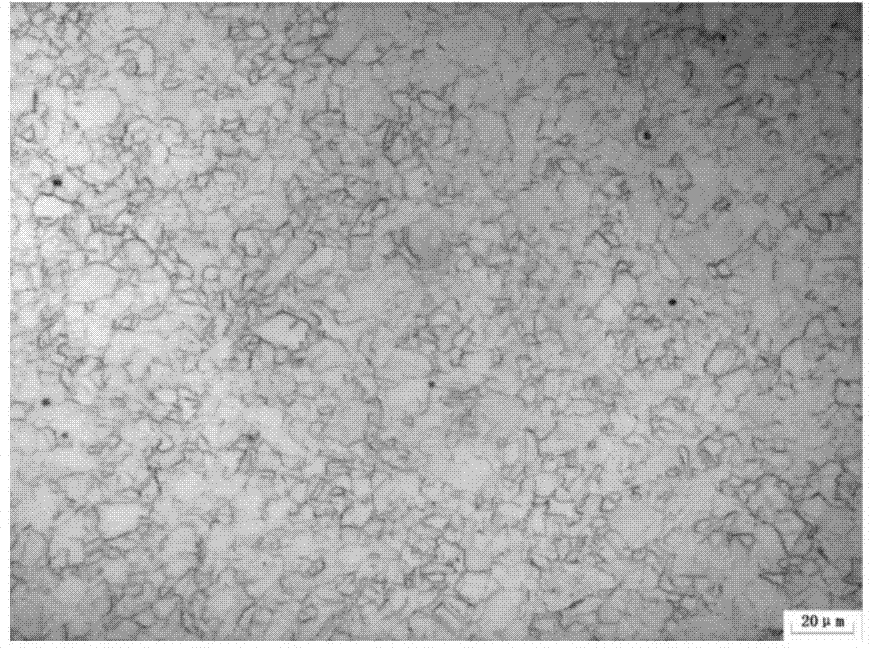

[0013] Although the current ultra-high-strength steel has good strength and toughness, it has low density, low service temperature, poor adiabatic shear resistance and high strain rate performance. Although traditional tungsten alloys such as W93 have high density, traditional metallurgical processes are not applicable. The tungsten alloy produced by the powder metallurgy process has low strength and poor toughness, the tensile strength of the normal sintered state reaches 800-1000MPa, and the elongation reaches 20-30%. two-phase structure

The organization lacks consistency and continuity, and the mechanical properties are not good under high strain rate loading conditions, which limits the prospect of a large number of popularization applications

For large-sized tungsten alloy parts, the requirements for deformation equipment are extremely high, and the deformation is also prone to unevenness, which affects the uniformity of the structure, which also determines that the mechanical properties of large-sized tungsten alloys are difficult to improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

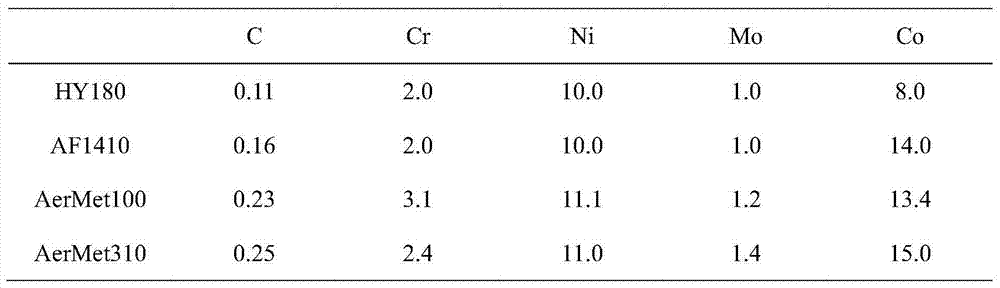

[0032] According to the chemical composition scope of economical high-toughness easy-spinning and easy-welding ultra-high-strength steel of the present invention, 25 kilograms of vacuum induction furnaces are used to prepare 20 kilograms of alloy ingots 15 furnaces, and their concrete chemical compositions are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-density high-toughness kinetic energy ultra-high-strength tungsten-nickel alloy, belongs to the field of heat-resisting alloys, and in particular relates to a high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy. The high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy comprises the following chemical compositions in percentage by weight: 50-80% of Ni, 20-40% of W, 0-3% of Ti, 0-3% of Al, 0-8% of Nb and the balance of other inevitable impurity elements and micro elements such as rare earth. A preparation method of the high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy adopts the following processes: vacuum induction and vacuum self-consuming remelting or electro-slag remelting. Compared with the prior art, the high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy disclosed by the invention has excellent comprehensive performance and excellent properties such as high density, high toughness, ultra-high strength and ultra-high dynamic strength, and ensures that the density can reach 9.0-13.0g / cm<3>, the impact toughness can reach more than 100J / cm<2>, the static tensile strength can reach more than 1350MPa, and the dynamic compressive strength can reach more than 1900MPa.

Description

technical field [0001] The invention belongs to the field of heat-resistant alloys, and in particular relates to a high-density, high-toughness, kinetic-energy, ultra-high-strength tungsten-nickel heat-resistant alloy DT730 and a preparation method. 9.0-13.0g / cm 3 , Impact toughness reaches 100J / cm 2 Above, the static tensile strength reaches 1350MPa or more, and the dynamic compressive strength reaches 1900MPa or more. Background technique [0002] Prior to this, high-density materials were mainly used in heat-resistant parts, protective parts, shielding parts, armor-piercing parts, etc. The commonly used tungsten alloy in the world is such a material. Due to the high melting point of tungsten, such materials are usually made of powder Metallurgical methods are sintered and formed. At present, the widely used tungsten alloys in the world are W90, W93, W95 and W97, etc. The density of such materials is very high, which can reach 15-18g / cm 3 , but the strength is low and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C19/03C22F1/10

Inventor 王春旭厉勇谭成文刘少尊于晓东王富耻黄顺喆韩顺刘宪民李建新庞学东

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com