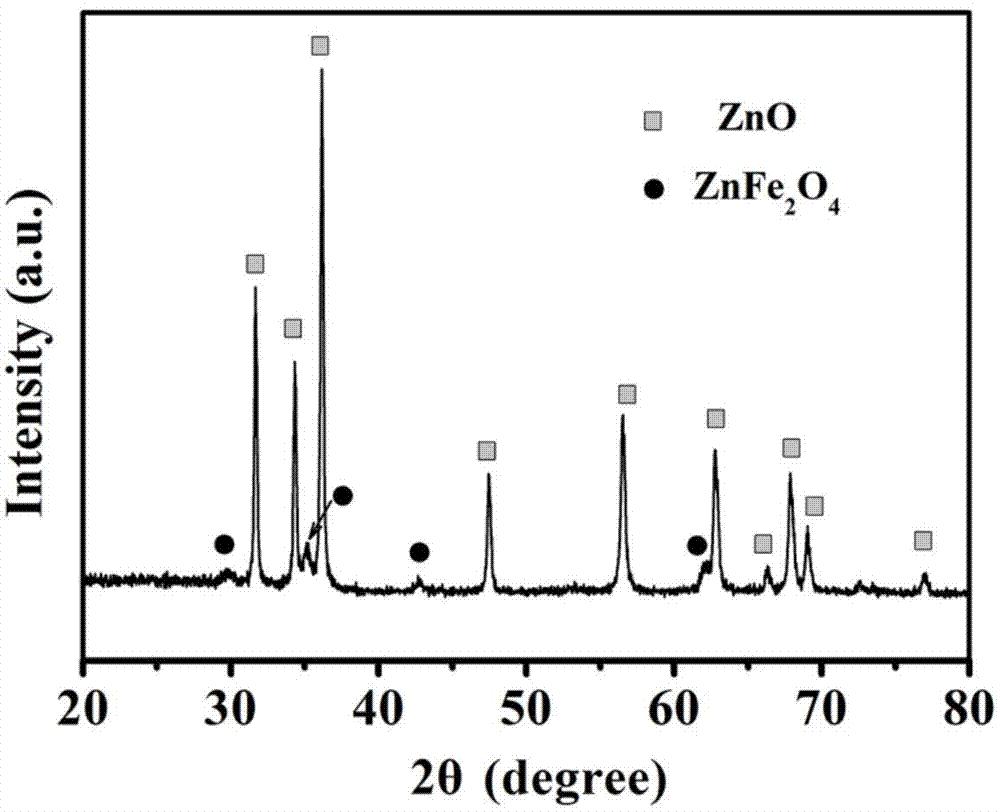

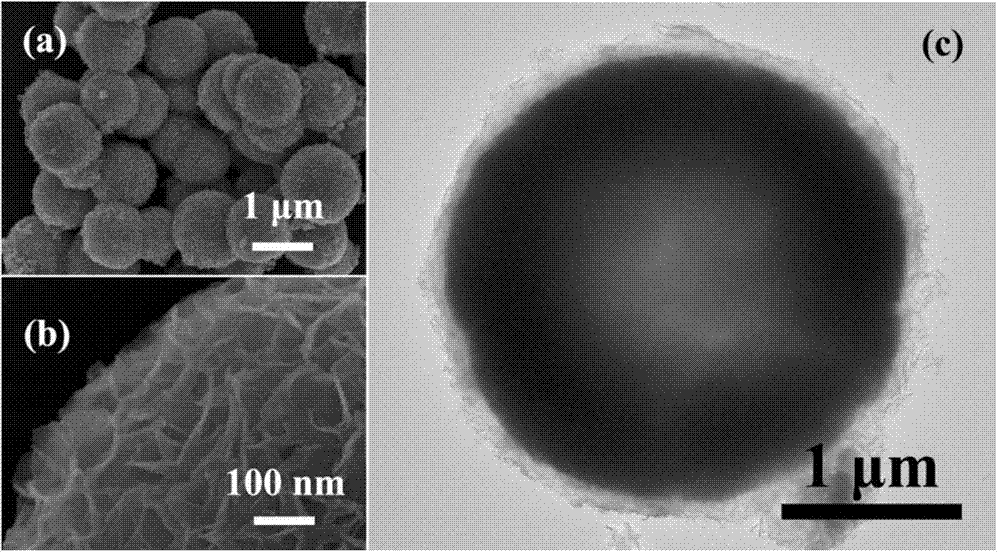

ZnO/ZnFe2O4 composite sensitive material, preparation method thereof and application of ZnO/ZnFe2O4 composite sensitive material in acetone gas sensor

A gas sensor, composite sensitive technology, applied in the application of acetone gas sensor, ZnO/ZnFe2O4 composite sensitive material field, can solve the problems of lengthy reaction process, harsh experimental conditions, cumbersome operating procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

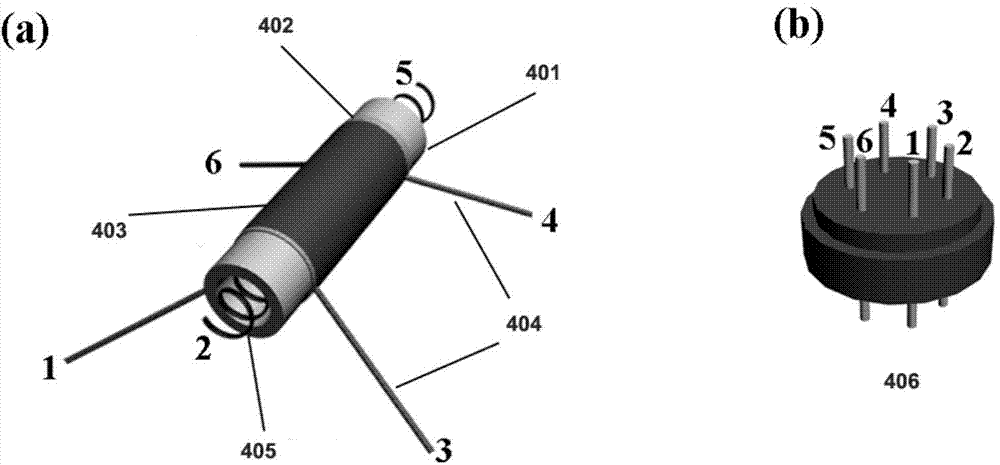

[0043] With ZnO / ZnFe 2 o 4 The heterogeneous structure is a sensitive material to make an acetone gas sensor, and the specific method is as follows:

[0044] ①Add 1.1g Zn(CH 3 COO) 2 2H 2 O and 0.0588g Na 3 C 6 h 5 o 7 2H 2 O was sequentially added to 200mL deionized water, kept stirring to make it fully dissolved, then measured 6mL ammonia water (30wt%) and added to the above solution, and kept stirring for 5min;

[0045] ② Transfer the obtained clear solution to a three-necked flask, and use microwave to heat the reaction solution to 90°C, set the heating time to 40min, and set the heating power to 300W;

[0046] ③ After the reaction, the microwave heating system automatically stops heating. After the reaction system is naturally cooled to room temperature, the three-necked flask is taken out, and the obtained white precipitate is alternately centrifuged and washed 6 times with deionized water and ethanol to wash off the remaining residue in the reaction solution. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com