3D printed tapered electrode structure of solar cell

A technology of solar cells and graded electrodes, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems affecting the collection effect of carriers, achieve enhanced carrier collection capabilities, improve conversion efficiency, and grid line shape Fine and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

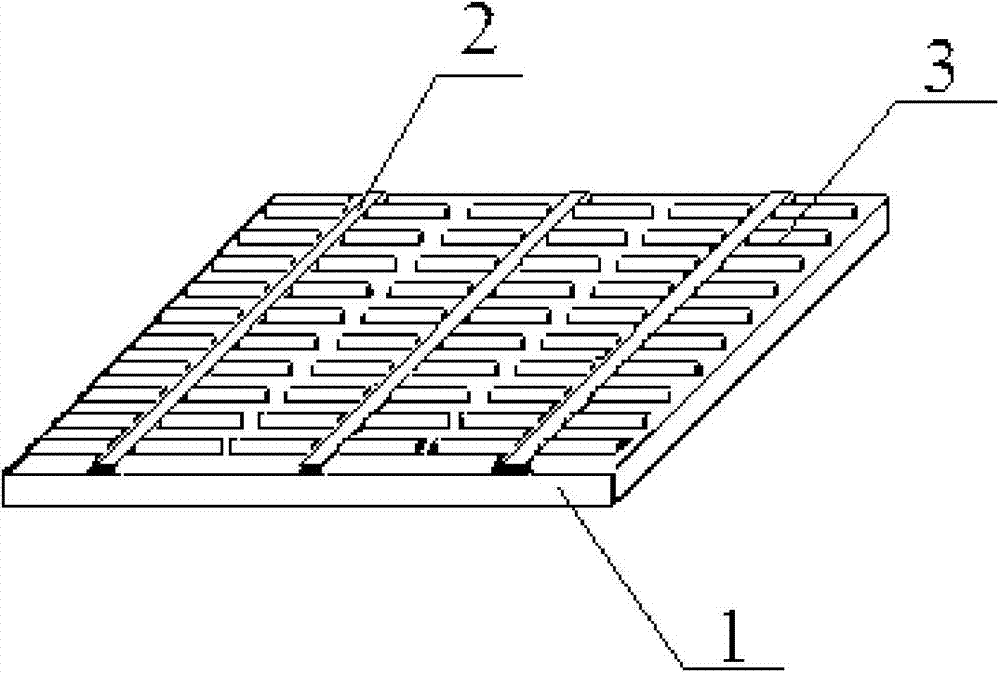

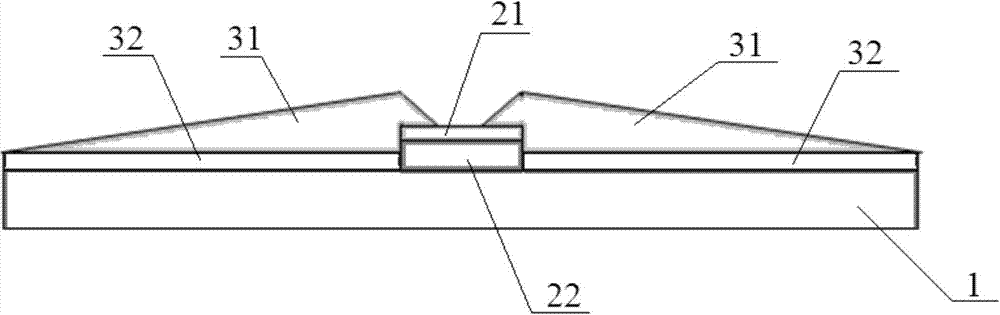

[0026] A 3D printed solar cell tapered electrode structure, such as figure 1 , figure 2 As shown, including the substrate 1, the main grid line 2 and the sub grid line 3, the main grid line 2 and the sub grid line 3 are formed by 3D printing, and the main grid line 2 and the sub grid line 3 are vertically intersected on the substrate 1 , and the sub-grid 3 is a segmented structure, the busbar 2 includes a busbar conductive layer 21 and a busbar seed layer 22, the busbar seed layer 22 is laid on the substrate 1, and the busbar conductive layer 21 is laid On the main grid line seed layer 22, the sub grid line 3 includes a sub grid line conductive layer 31 and a sub grid line seed layer 32, the sub grid line seed layer 32 is laid on the substrate 1, and the sub grid line conductive layer 31 is laid on the sub grid line On the grid line seed layer 32 , the auxiliary grid line conductive layer 31 is a tapered layered body.

[0027] The sub-grid conductive layer 31 is a tapered l...

Embodiment 2

[0034] A 3D printed solar cell tapered electrode structure, such as figure 1 , figure 2 As shown, including the substrate 1, the main grid line 2 and the sub grid line 3, the main grid line 2 and the sub grid line 3 are formed by 3D printing, and the main grid line 2 and the sub grid line 3 are vertically intersected on the substrate 1 , and the sub-grid 3 is a segmented structure, the busbar 2 is a complete structure, the busbar 2 includes a busbar conductive layer 21 and a busbar seed layer 22, and the busbar seed layer 22 is laid on the substrate 1 , the main grid line conductive layer 21 is laid on the main grid line seed layer 22, the sub grid line 3 includes the sub grid line conductive layer 31 and the sub grid line seed layer 32, the sub grid line seed layer 32 is laid on the substrate 1, the sub grid line The grid line conductive layer 31 is laid on the auxiliary grid line seed layer 32 , and the auxiliary grid line conductive layer 31 is a tapered layered body.

...

Embodiment 3

[0042] A 3D printed solar cell tapered electrode structure, such as figure 1 , figure 2 As shown, including the substrate 1, the main grid line 2 and the sub grid line 3, the main grid line 2 and the sub grid line 3 are formed by 3D printing, and the main grid line 2 and the sub grid line 3 are vertically intersected on the substrate 1 , and the sub-grid 3 is a segmented structure, the busbar 2 is a complete structure, the busbar 2 includes a busbar conductive layer 21 and a busbar seed layer 22, and the busbar seed layer 22 is laid on the substrate 1 , the main grid line conductive layer 21 is laid on the main grid line seed layer 22, the sub grid line 3 includes the sub grid line conductive layer 31 and the sub grid line seed layer 32, the sub grid line seed layer 32 is laid on the substrate 1, the sub grid line The grid line conductive layer 31 is laid on the auxiliary grid line seed layer 32 , and the auxiliary grid line conductive layer 31 is a tapered layered body.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com