A thermal shrinkage forming method of a variable cross-section rectangular tube C-beam

A technology of rectangular tubes and variable cross-sections, which is applied in the field of processing and forming variable cross-section beams, can solve the problem of welding butt joint gaps, weld thickness, molten pool depth is difficult to grasp, molten pool metallurgical reactions cannot be controlled by workers, and ultrasonic flaw detection inspections take a lot of time and other issues, to achieve the effect of easy quality assurance, stable size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

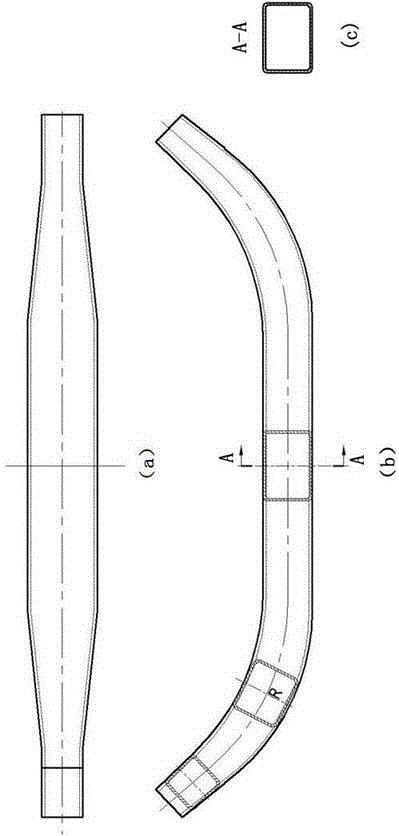

[0050] In order to clearly illustrate the technical features of this solution, the following describes the solution through specific implementations and in conjunction with the accompanying drawings.

[0051] A heat-shrink forming method for a C-beam of a variable section rectangular tube, which includes the following steps:

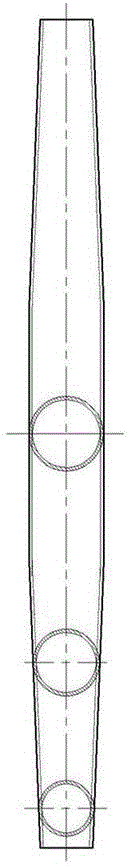

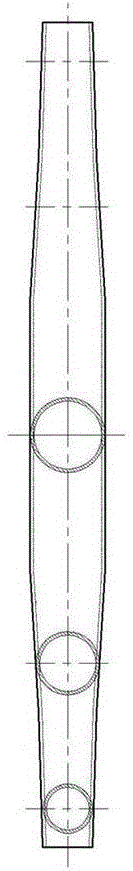

[0052] (1) Equal reduction in diameter: The two ends of the seamless round pipe are heated to 900-980℃ in an intermediate frequency furnace. Preferably, the seamless round pipe is a seamless steel pipe with a thickness of 6-7mm, which is used on the extrusion equipment The necking mold performs equal diameter reduction, and the two ends of the round tube are made into a conical tube, and the small end of the conical tube is outside, and the conical tubes at both ends have an equal cone angle, and the cone angle of the conical tube after equal reduction in diameter It is 1.5゜-4゜, preferably the cone angle of the conical tube after the same reduction is 2.2゜, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com