Preparation method of polymer microspheres with granularity gradient characteristics as well as prepared polymer microspheres and application of polymer microspheres

A particle size gradient and polymer technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of reduced, disappear, and destroyed stabilizing effects, and achieve stable and long-lasting effects with good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

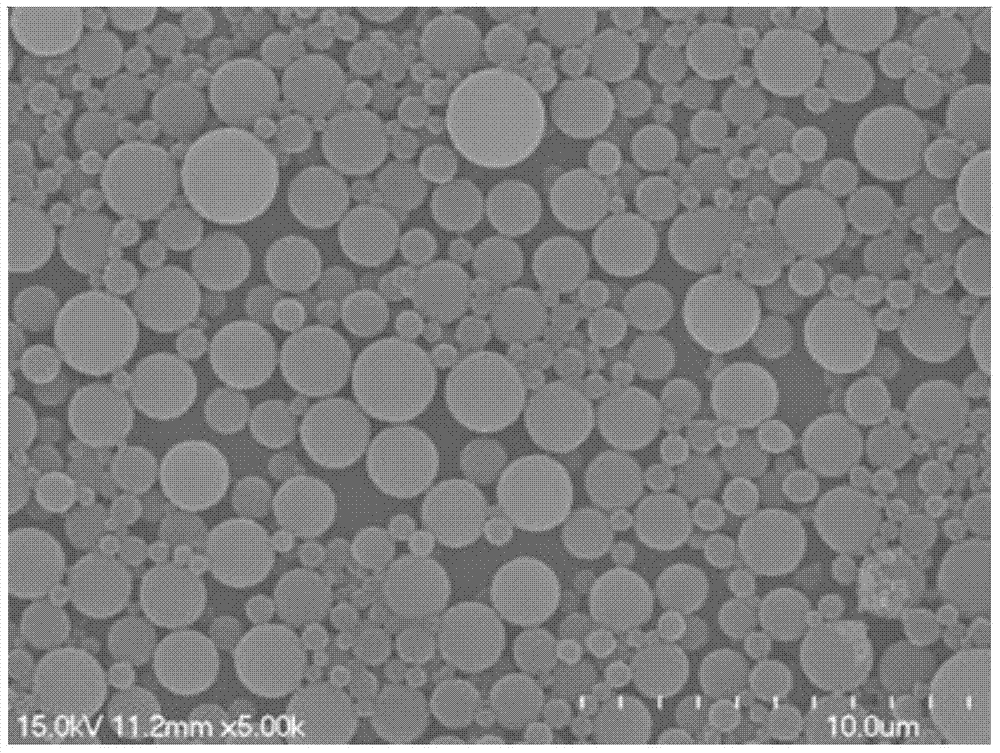

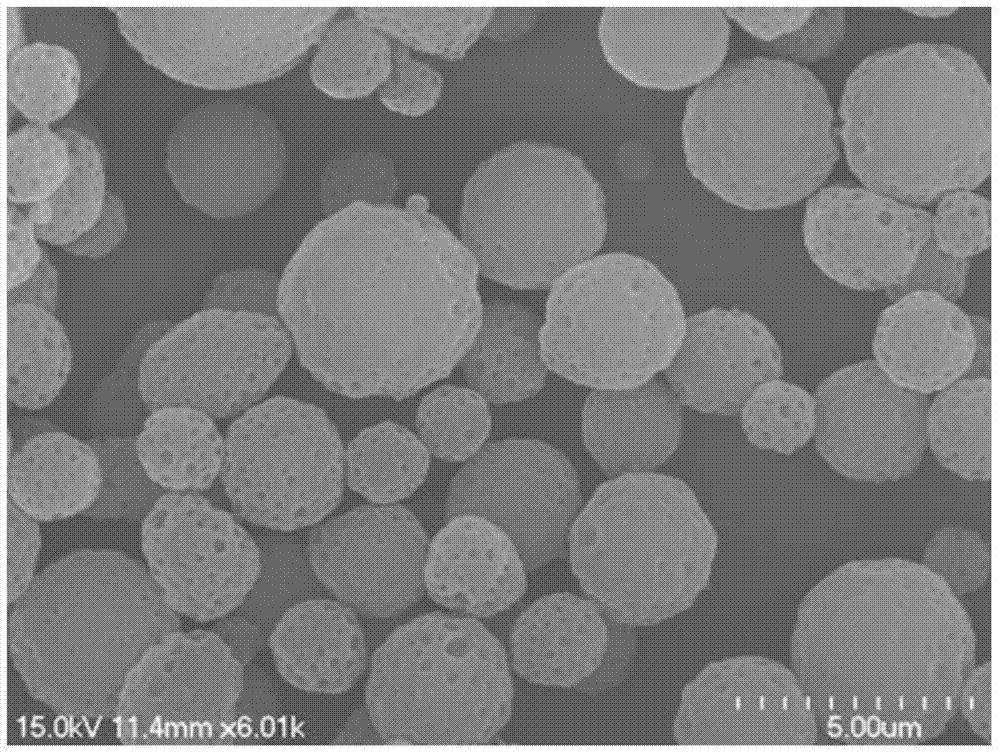

[0028] The preparation method of the polymer microsphere with particle size gradient characteristic of the present invention is generally prepared by reacting a monomer and a polymerizable dispersion stabilizer as raw materials in a dispersion medium.

[0029] The amount of monomer used is 20-30% of the total amount of the system, and if necessary, functional monomers are added, and the amount of monomer used is 2-25% of the dispersion stabilizer, and the dispersion medium is mixed evenly at room temperature. Afterwards, under the action of an initiator, the temperature is maintained at 70-90° C. for 3-5 hours to obtain polymer microspheres, that is, the polymer microspheres with particle size gradient characteristics. When the conversion rate reaches over 95%, the reaction is completed, and the obtained product is subjected to centrifugal washing to obtain polymer microspheres.

[0030] The dispersion stabilizer used in the present invention is a polymerizable epoxy resin dis...

Embodiment 1

[0048] Aromatic bisphenol A type epoxy resin E44 and acrylic acid in a molar ratio of 1:1.1 are fully reacted at 90°C for 2 to 2.5 hours to obtain a single epoxy modified epoxy resin with a double bond at one end, and then Add the calculated amount of polyethylene glycol 6000, and fully react for 1.0 h at 85°C to obtain a polymerizable bisphenol A type epoxy resin dispersion stabilizer.

Embodiment 2

[0050] After the aliphatic epoxy resin ethylene glycol diglycidyl ether and acrylic acid have a molar ratio of 1:1.1 at 90°C, react fully for 1.5 to 2 hours to obtain a single-epoxy group-modified epoxy resin with one end capped, and then Add the calculated amount of polyethylene glycol 2000 and fully react for 1.0 h at 80°C to obtain a polymerizable aliphatic epoxy resin dispersion stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com