Preparation method for hollow titanium dioxide/polyacrylate composite film with insulation performance

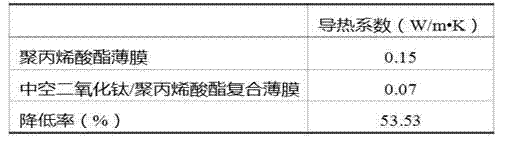

A polyacrylate, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high hydrolysis activity and complex process, and achieve the effect of improving thermal insulation performance and thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the hollow titanium dioxide / polyacrylate composite film with thermal insulation performance that the present invention relates to comprises the following steps:

[0023] (1) Disperse 0.3-0.5g of polystyrene microspheres in 30-35g of absolute ethanol, and ultrasonically treat it for 5-10 minutes to form a mixed solution A;

[0024] (2) Add 0.2-0.37g of butyl titanate to 15g of absolute ethanol and stir evenly to form a mixed solution B;

[0025] (3) Add the mixed solution B and 2.5-5.0 g of ammonia water with a concentration of 28wt% dropwise into the mixed solution A at the same time, the dropping time is controlled at 30-60 minutes, and then stirred in a water bath at room temperature for 1-1.5 hours;

[0026] (4) Warm up the water bath to 50°C and stir mechanically for 2-4 hours to obtain a white suspension;

[0027] (5) Centrifuge the white suspension obtained in step (4), wash the product with absolute ethanol for 3 to 5 times, and then pu...

Embodiment 1

[0031] (1) Disperse 0.3g of polystyrene microspheres in 35g of absolute ethanol, and ultrasonicate for 5 minutes to form a mixed solution A;

[0032] (2) Add 0.37g of butyl titanate to 15g of absolute ethanol and stir evenly to form a mixed solution B;

[0033] (3) Add the mixed solution B and 2.5g of ammonia water with a concentration of 28wt% dropwise to the mixed solution A at the same time, the dropping time is controlled at 60min, and then stirred in a water bath at room temperature for 1h;

[0034] (4) Warm up the water bath to 50°C and stir mechanically for 4 hours to obtain a white suspension;

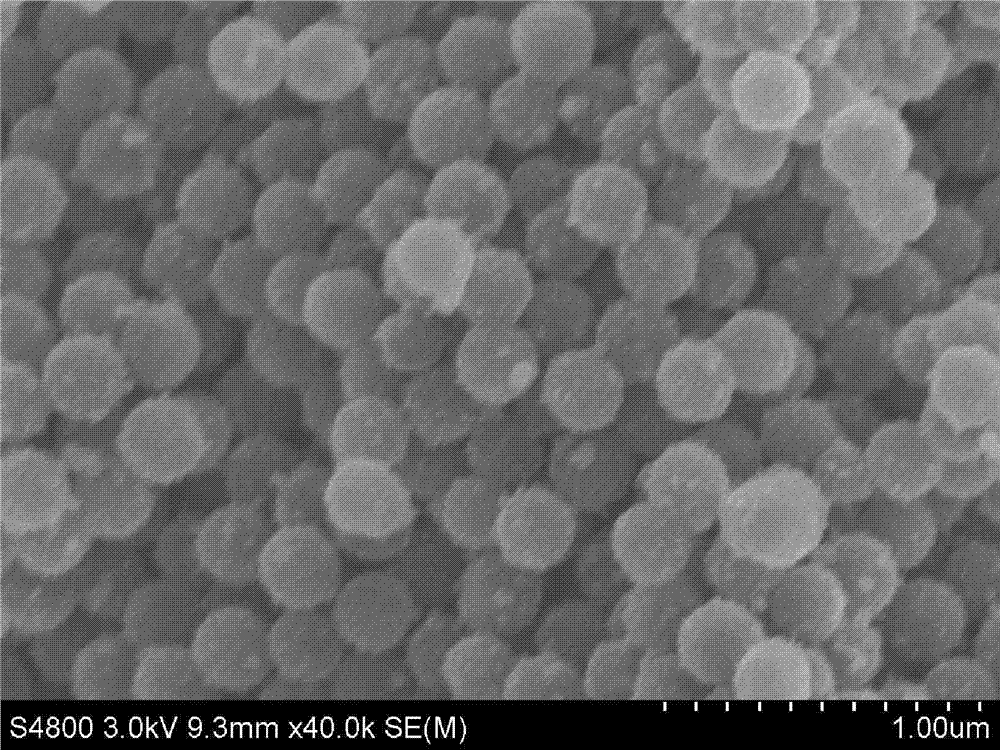

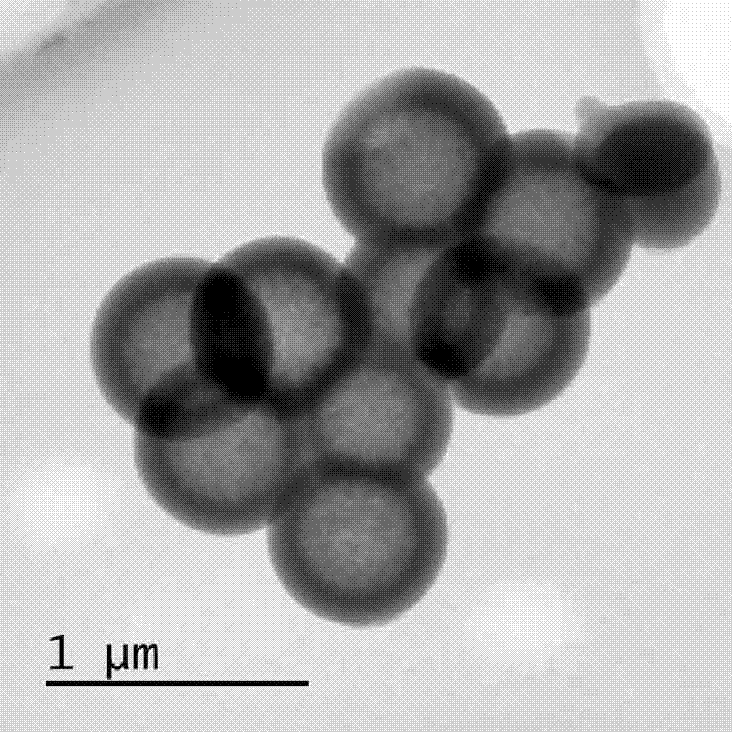

[0035] (5) Centrifuge the white suspension obtained in step (4), wash the product 3 times with absolute ethanol, and then put the washed product in an oven at 60°C for 15 hours to obtain hollow titanium dioxide particles;

[0036] (6) Ultrasonic disperse 0.2 g of hollow titanium dioxide particles obtained in step (5) in 18 g of distilled water, mix and stir it with 30 g of pol...

Embodiment 2

[0039] (1) Disperse 0.4g of polystyrene microspheres in 32g of absolute ethanol, and ultrasonicate for 7min to form a mixture A;

[0040] (2) Add 0.3g of butyl titanate to 15g of absolute ethanol and stir evenly to form a mixed solution B;

[0041] (3) Add the mixed solution B and 3.7g of ammonia water with a concentration of 28wt% to the mixed solution A dropwise at the same time, the dropping time is controlled at 45min, and then stirred in a water bath at room temperature for 1.2h;

[0042] (4) Warm up the water bath to 50°C and stir mechanically for 3 hours to obtain a white suspension;

[0043] (5) Centrifuge the white suspension obtained in step (4), wash the product 4 times with absolute ethanol, and then dry the washed product in a 60°C oven for 13 hours to obtain hollow titanium dioxide particles;

[0044] (6) Ultrasonic disperse 0.4g of hollow titanium dioxide particles obtained in step (5) in 16g of distilled water, mix and stir it with 25g of polyacrylate emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com