Nitrile rubber of peroxide fast curing system and preparation method thereof

A technology of nitrile rubber and peroxide, which is applied in the field of rubber, can solve the problems of slow vulcanization rate of nitrile rubber, difficulty in demoulding, and low copper corrosion resistance, and achieve the goals of reducing vulcanization time, improving performance, and increasing vulcanization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

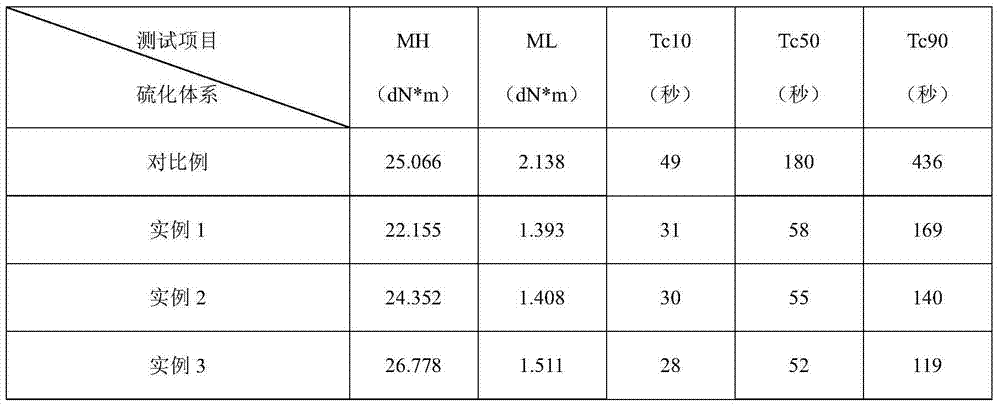

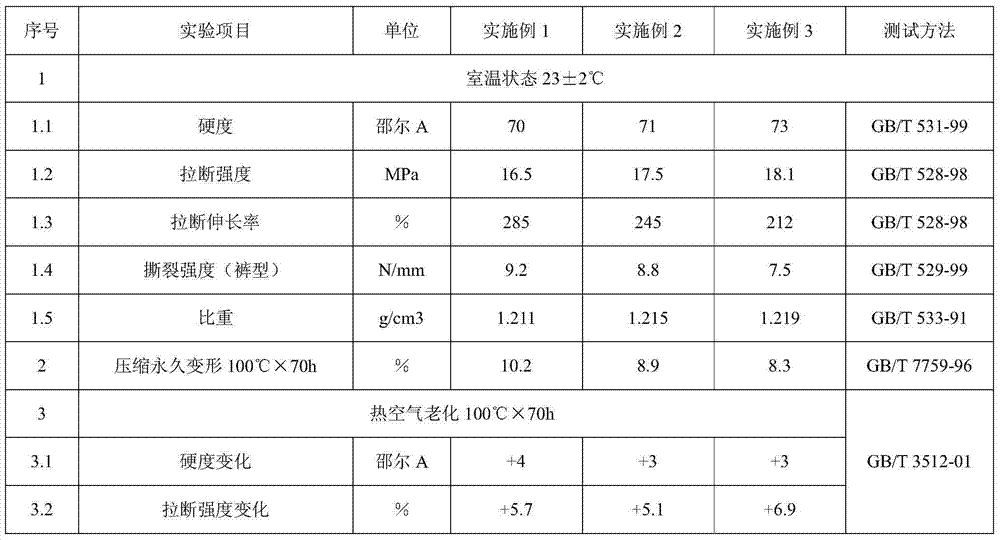

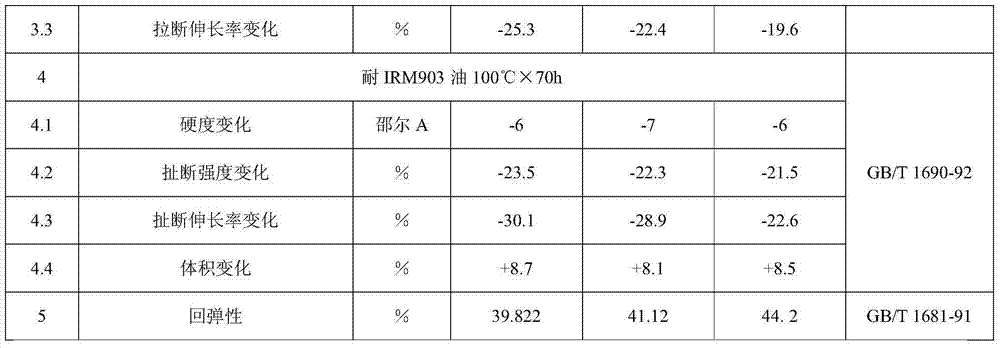

Examples

Embodiment 1

[0020] 100 parts by mass of JSR230S nitrile rubber raw rubber, 2 parts by mass of antioxidant KY-405, 65 parts by mass of carbon black, 8 parts by mass of DOS plasticizer, 5 parts by mass of zinc stearate, 5 parts by mass of DC40P-SP2L, 1.5 parts by mass The mass parts of TAIC were put into the open mixer and fully mixed for 3 minutes. When the temperature in the internal mixing room reached 110°C, the rubber material was discharged, and the masterbatch was obtained by rapid blast cooling. Then, the masterbatch is passed through a screw extruder and a required die to obtain a preformed sample of a predetermined size. Finally, put the preformed sample into the mold of a flat vulcanizer, pressurize it to 15MPa, and vulcanize at a vulcanization temperature of 175°C for 170s to obtain nitrile rubber.

Embodiment 2

[0022] 100 parts by mass of JSR230S nitrile rubber raw rubber, 2 parts by mass of antioxidant MBZ, 65 parts by mass of carbon black, 8 parts by mass of TOTM plasticizer, 5 parts by mass of zinc stearate, 7 parts by mass of Luperox233XL, and 2 parts by mass of TAIC Put it into the open mill for full mixing for 4.5min. When the temperature in the mixing room reaches 110°C, the rubber material is discharged, cooled by rapid air blast, and the masterbatch is obtained. Then, the masterbatch is passed through a screw extruder and a required die to obtain a preformed sample of a predetermined size. Finally, put the preformed sample into the mold of a flat vulcanizer, pressurize it to 25MPa, and vulcanize it at a vulcanization temperature of 185°C for 120s to obtain nitrile rubber.

Embodiment 3

[0024] 100 parts by mass of JSR230S nitrile rubber raw rubber, 2 parts by mass of antioxidant MBZ, 65 parts by mass of carbon black, 8 parts by mass of TOTM plasticizer, 5 parts by mass of zinc stearate, 8 parts by mass of Luperox233XL, and 2.4 parts by mass of TAIC Put it into the open mill for full mixing for 4.5min. When the temperature in the mixing room reaches 110°C, the rubber material is discharged, cooled by rapid air blast, and the masterbatch is obtained. Then, the masterbatch is passed through a screw extruder and a required die to obtain a preformed sample of a predetermined size. Finally, put the preformed sample into the mold of a flat vulcanizer, pressurize it to 20MPa, and vulcanize it at a vulcanization temperature of 180°C for 145s to obtain nitrile rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com