Method and equipment for sodium removal of high sodium coal

A high-sodium coal, sodium removal technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of coking heating surface, corrosion, contamination, etc., achieve high water recovery rate, expand sales scope, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

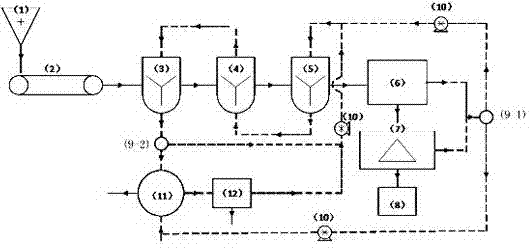

[0039] A high-sodium coal desodium equipment, including a crusher 1, a belt conveyor 2, a coal washer, a vibrating dewatering screen 6, a centrifugal dehydrator 7, a coal bunker 8, a sodium ion measuring instrument, a pressure pump 10, and a concentration pool 11 , the reverse osmosis water purification device 12, the crusher 1 is connected with the belt conveyor 2;

[0040] There are 3 stages of coal washer, and each stage of coal washer is equipped with two inlets and two outlets, which are respectively used for input and output of coal samples and aqueous solution;

[0041] The solid inlet of the first-stage coal washer 3 is connected with the belt conveyor 2, and the solid outlet of the first-stage coal washer 3 is connected with the solid inlet of the second-stage coal washer 4;

[0042] The solid outlet of the second-stage coal washer 4 is connected to the solid inlet of the third-stage coal washer 5, the solid outlet of the third-stage coal washer 5 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com