A kind of asphalt mixture for cement concrete pavement thin layer covering and its preparation and construction method

A technology of asphalt mixture and cement concrete, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of high requirements on raw materials, and achieve the effect of excellent performance, improving the quality of the road surface and improving the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Components:

[0032] Aggregate: basalt, the largest nominal particle size is 6.7mm, purchased from Jiangsu Xingyuan Mining Co., Ltd.;

[0033] Filler: copper tailings powder, which can be selected from local or surrounding mines;

[0034] Among them, the weight ratio of aggregates and fillers is 96%: 4%. For the convenience of description, aggregates and fillers are collectively referred to as "mineral materials" here, and the gradation of mineral materials is shown in Table 1.

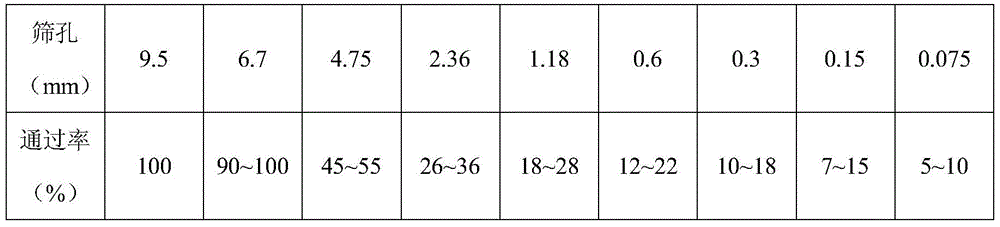

[0035] Table 1 Mineral material grading

[0036]

[0037] Asphalt: SBS polymer modified asphalt, the asphalt ratio is 5.8%, wherein the asphalt ratio is the ratio of asphalt to mineral aggregate weight, the asphalt was purchased from Jiangsu Baoli Asphalt Co., Ltd.

[0038] Fiber stabilizer: polyester fiber, the dosage is 0.2% of the mineral weight, purchased from Changzhou Zhuwei Building Materials Co., Ltd.

[0039] Additives: Composite synergist and warm mixing agent are mixed, and...

Embodiment 2

[0057] (1) Components:

[0058] Aggregate: limestone, the largest nominal particle size is 6.7mm, purchased from Jiangsu Xingyuan Mining Co., Ltd.;

[0059] Filler: copper tailings powder, which can be selected from local or surrounding mines;

[0060] Wherein, the weight ratio of aggregate and filler is 95%: 5%;

[0061] Mineral material grading see Table 3

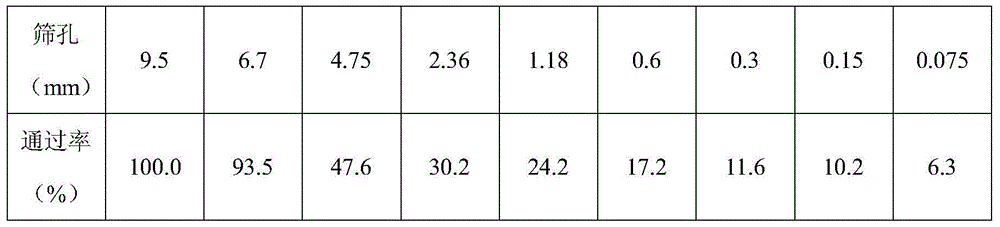

[0062] Table 3 Mineral material grading

[0063]

[0064] Asphalt: Heavy traffic 70#A grade asphalt, with an asphalt ratio of 6.1%, was purchased from Jiangsu Zhongyou Xingneng Asphalt Co., Ltd.

[0065] Fiber stabilizer: lignin fiber, the dosage is 0.3% of the mineral weight, purchased from Changzhou Zhuwei Building Materials Co., Ltd.

[0066] Additive: It is composed of compound synergist and warm mixing agent. The former is 0.6% of the mass of the mineral material, and the latter is 0.4% of the mass of the mineral material. The compound synergist is purchased from Shanghai Honeywell Co., Ltd., temperature Mix...

Embodiment 3

[0076] (1) Components:

[0077] Aggregate: diabase, the largest nominal particle size is 6.7mm, purchased from Jiangsu Xingyuan Mining Co., Ltd.;

[0078] Filler: copper tailings powder, which can be selected from local or surrounding mines;

[0079] Wherein, the weight ratio of aggregate and filler is 96%: 4%;

[0080] Mineral material grading see Table 5

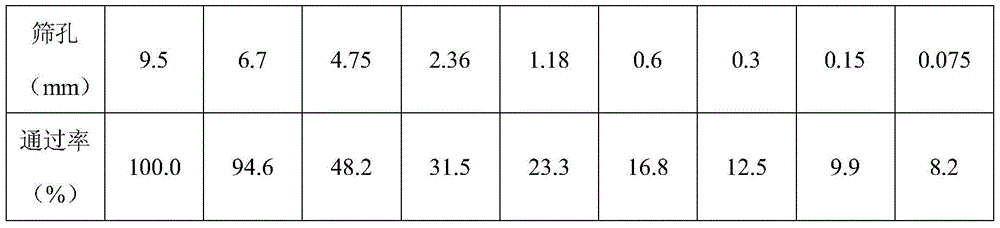

[0081] Table 5 Mineral material grading

[0082]

[0083] Asphalt: SBS polymer modified asphalt asphalt, the asphalt ratio is 5.6%, purchased from Jiangsu Baoli Asphalt Co., Ltd.

[0084] Fiber stabilizer: polyester fiber, the dosage is 0.15% of the mineral weight, purchased from Changzhou Zhuwei Building Materials Co., Ltd.

[0085] Additive: compound synergist, the dosage is 0.5% of the mass of mineral material, and the compound synergist is purchased from Shanghai Honeywell Co., Ltd. Warm mix agent is not used here because the temperature is relatively high, and the asphalt mixture can be better paved and compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com