High refractive (META)acrylate and the method for preparing the same

A technology of methacrylic acid and acrylate, applied in the field of high-refractive-index acrylate derivatives and their preparation, can solve the problems of processing, decrease in price competition rate, influence on display color, etc., and achieve excellent formability and adhesion, flow Good properties, moldability, and excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] And, the present invention provides a kind of preparation method of high refractive index (meth)acrylate derivative, comprises the following steps:

[0047] 1) fluorene derivatives, PFA (paraformaldehyde) and acid of the following chemical formula a are dropped into the first reactor, and they are reacted to prepare compounds of the chemical formula b; 2) KOH aqueous solution and the following The methacrylic acid of chemical formula c is then dropped into TBAB (Tetra-n-butylammonium bromide) to prepare KOH / methacrylic acid aqueous solution; 3) the reaction product of the step 1) is put into 2) In the second reactor of step, make it carry out esterification reaction, prepare the (meth)acrylate derivative of following chemical formula 1:

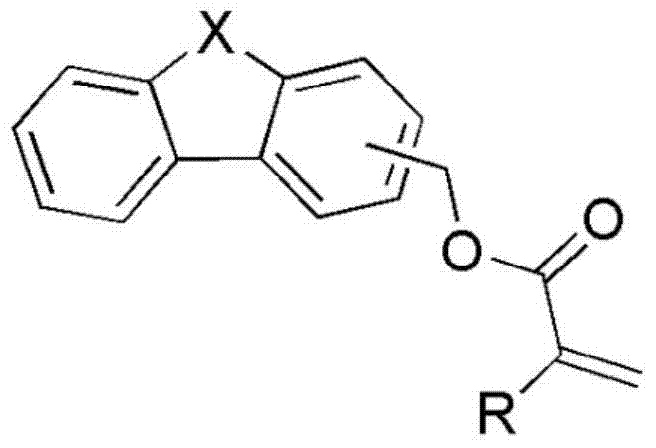

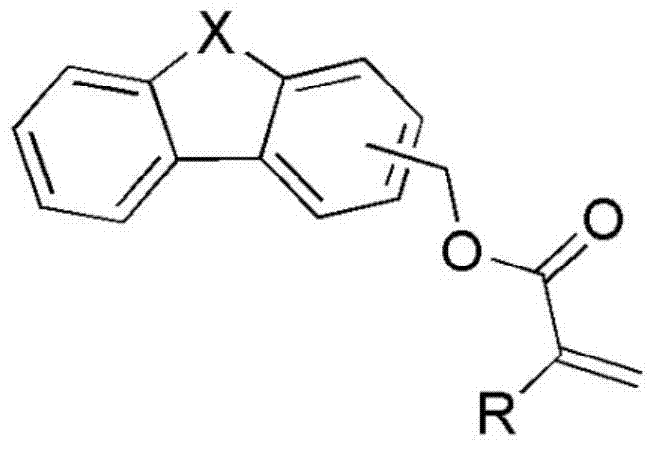

[0048] [chemical formula 1]

[0049]

[0050] [chemical formula a]

[0051]

[0052] [chemical formula b]

[0053]

[0054] [chemical formula c]

[0055]

[0056] Wherein X is O or S, R is cyano or methyl.

[0057] The...

Embodiment 1

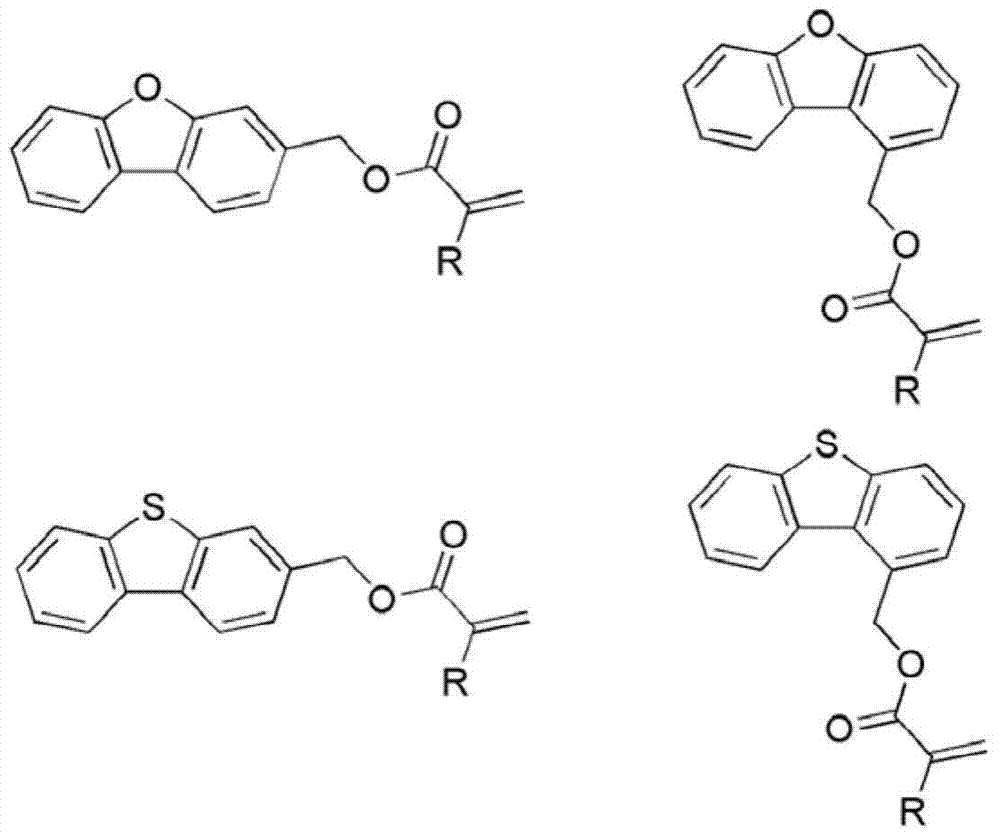

[0068] Synthesis of Dibenzo[b,d]furanylmethyl acrylate

[0069]

[0070] Add dibenzofuran (100.0g, 0.595mol), PFA (paraformaldehyde) (44.6g, 1.486mol), distilled water (50g) and acetic acid (100.0g) into a 1L reactor, stir and heat up to 80°C . The internal temperature of the reactor was maintained at 80° C., HCl gas (54.2 g, 1.486 mol) was added, and reacted for 5 hours. After completion of the reaction, toluene (300.0 g) was thrown in, and chloromethyl-containing dibenzofuran was separated as an intermediate product by layer separation. Stir the intermediate product layer, and cool the internal temperature of the reactor to 25° C., wash with water three times and separate the layers with distilled water (200.0 g) each time, and utilize activated carbon to decolorize the intermediate product layer in order to improve the color of the final target compound. After decolorization, MgSO 4 Water was removed and filtered, and a polymerization inhibitor MEHQ (4-Methoxy Phenol)...

Embodiment 2

[0076] Synthesis of Dibenzo[b,d]thiophenylmethyl acrylate

[0077]

[0078] Add dibenzothiophene (100.0 g, 0.543 mol), PFA (paraformaldehyde) (40.7 g, 1.357 mol), distilled water (50 g) and acetic acid (100.0 g) into a 1 L reactor, stir, and heat up to 90 ° C . The internal temperature of the reactor was maintained to 90° C., HCl gas (49.5 g, 1.356 mol) was added and reacted for 5 hours. After the reaction was completed, toluene (300.0 g) was dropped in, and dibenzothiophene containing chloromethyl was separated as an intermediate product through layer separation. The intermediate product layer was stirred, and the internal temperature of the reactor was cooled to 25° C., each time with distilled water (200.0 g), through 3 times of water washing and layer separation, to improve the color of the final target compound, the intermediate product layer was decolorized by activated carbon. After decolorization, MgSO 4 Water was removed and filtered, and a polymerization inhibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com