Method for preparing hedenbergite glass ceramics by using lead slag

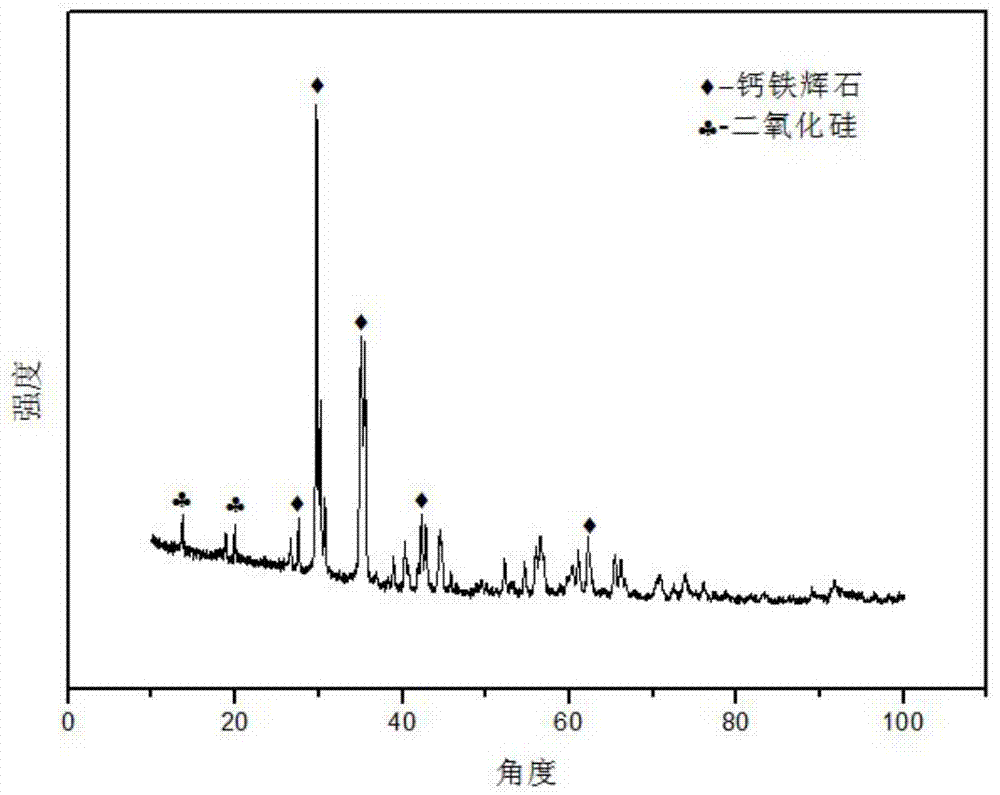

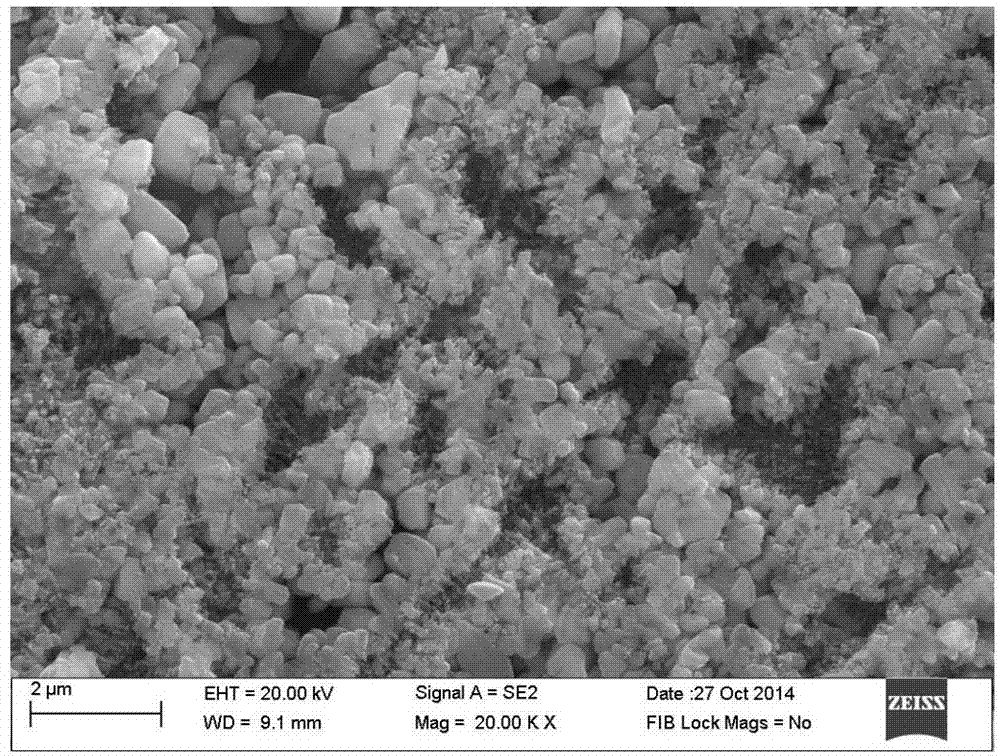

A technology of glass-ceramic and calcium iron pyroxene, which is applied in the fields of preparing glass-ceramic products from solid waste, environmental protection and resource reuse, can solve the problems of secondary pollution, lead slag cannot be added to cement kiln, etc., and achieve Good environmental and social benefits, excellent performance, uniform composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

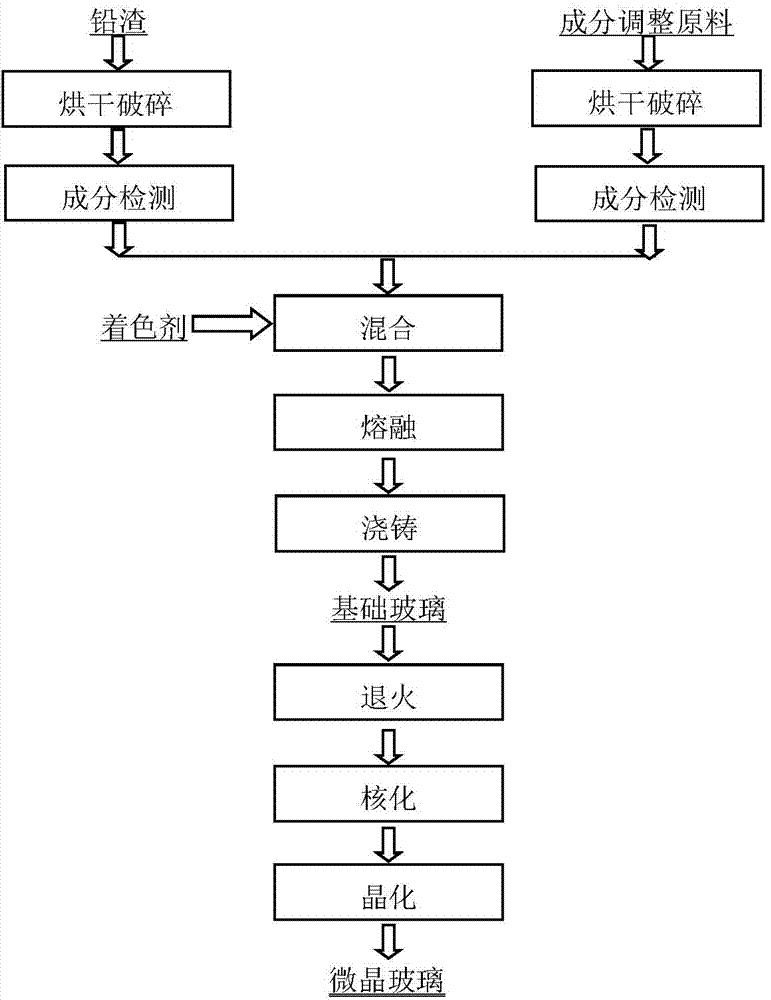

Method used

Image

Examples

Embodiment 1

[0024] The high-iron lead slag and fly ash are dried and crushed to -100 mesh respectively; the ingredients are tested separately, and the amount of high-iron lead slag, fly ash and pyrolusite is calculated according to the stoichiometric ratio in the table below, and mixed; The final material is heated to 1450°C in the melting furnace at a rate of 7°C / min for melting to a molten state, and is kept for 2 hours to obtain a uniform glass liquid, which is cast into a mold at 580°C to obtain a basic glass; the basic glass is kept at 600°C Annealed for 30 minutes; the annealed base glass was held at 700°C for 50 minutes for nucleation; the base glass after nucleation was held for 2 hours at 900°C for crystallization to obtain glass-ceramics.

[0025] In this embodiment, the glass-ceramic main element content is as follows:

[0026] the element

Fe 2 o 3

SiO 2

CaO

Al 2 o 3

Na 2 o

MgO

ZnO

RO

content

26

40

12

5...

Embodiment 2

[0031] The lead-zinc rotary kiln slag and waste glass are dried and crushed to -100 mesh respectively; the ingredients of the materials are tested respectively, and the amount of lead-zinc rotary kiln slag, waste glass and chromium oxide is calculated according to the stoichiometric ratio in the table below, and mixed ;The mixed material is heated to 1500°C at a rate of 10°C / min in the melting furnace to be smelted to a molten state, kept warm for 2 hours to obtain a uniform glass liquid, and cast into a mold at 600°C to obtain a basic glass; the basic glass is heated at 600°C Annealing was carried out at lower temperature for 30 minutes; the annealed base glass was incubated at 700°C for 60 minutes for nucleation; the nucleated base glass was crystallized at 900°C for 2 hours to obtain glass-ceramics.

[0032] In this embodiment, the glass-ceramic main element content is as follows:

[0033] the element

Fe 2 o 3

SiO 2

CaO

Al 2 o 3

Na 2 ...

Embodiment 3

[0038]The lead fume slag, high iron lead slag and waste glass are dried and crushed to -100 mesh respectively; the components of the materials are tested respectively, and the lead fume slag, high iron lead slag, waste glass and nickel oxide are calculated according to the stoichiometric ratio in the following table The mixed material is heated to 1550°C at a rate of 10°C / min in the melting furnace to be melted to a molten state, kept for 2.5 hours to obtain a uniform molten glass, and cast into a mold at 550°C to obtain a base Glass; the basic glass is annealed at 600°C for 40 minutes; the annealed basic glass is held at 750°C for 60 minutes for nucleation; the nucleated basic glass is crystallized at 900°C for 2 hours to obtain glass ceramics.

[0039] In this embodiment, the glass-ceramic main element content is as follows:

[0040] the element

Fe 2 o 3

SiO 2

CaO

Al 2 o 3

Na 2 o

MgO

ZnO

RO

content

22

44

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com