Wood surface protection nano coating and manufacturing technology thereof

A nano-coating, wood surface technology, used in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of wood surface fullness, color saturation, texture, permeability and surface hardness. Poor, unclean and other problems, to achieve the effect of easy cleaning of permeability, easy cleaning of surface hardness, and improvement of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of technique for preparing wood surface protective nano-coating, this technique comprises the steps:

[0020] 1) Add 25.5Kg of n-butanol into the reaction kettle, then add 25Kg of nano-silica while stirring, and stir for 30 minutes.

[0021] 2) Add 5.5Kg of butyl acetate and 3.5Kg of ethyl orthosilicate into the reaction kettle, and stir for 1 hour.

[0022] 3) Add 1.5Kg of sodium carboxymethylcellulose and 3.5Kg of silane coupling agent (KH570) into the reaction kettle, and stir for 1 hour.

[0023] 4) Add 15.5Kg of isocyanate and 15.5Kg of polyethylene glycol ether into the reaction kettle, and stir for 1 hour to obtain a nano-coating for wood surface protection.

[0024] 5) Sealing and filling nano-coatings for wood surface protection must be completed within 1 hour.

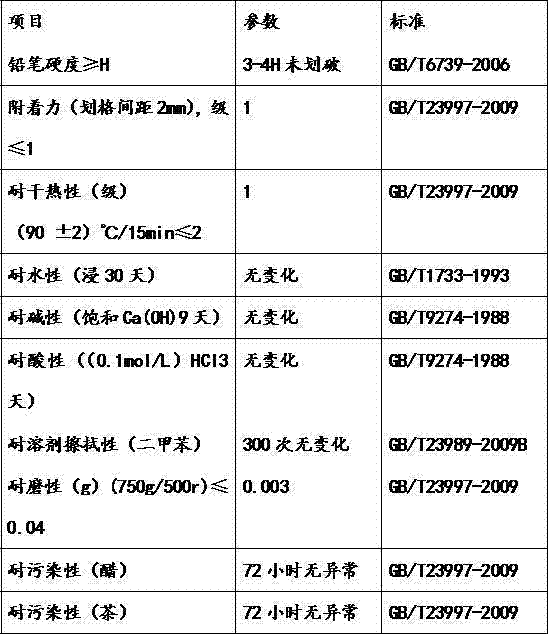

[0025] The prepared wood surface protective nano-coating is used on the surface of wood, and the experimental test index:

[0026]

Embodiment 2

[0028] A kind of technique for preparing wood surface protective nano-coating, this technique comprises the steps:

[0029] 1) Add 26.0Kg of n-butanol into the reaction kettle, then add 26Kg of nano silicon dioxide while stirring, and stir for 30 minutes.

[0030] 2) Add 6.0Kg of butyl acetate and 4.0Kg of ethyl orthosilicate into the reaction kettle, and stir for 1 hour.

[0031] 3) Add 2.0Kg of sodium carboxymethylcellulose and 4.0Kg of silane coupling agent (KH570) into the reaction kettle, and stir for 1 hour.

[0032] 4) Add 16.0Kg of isocyanate and 16.0Kg of polyethylene glycol ether into the reaction kettle, and stir for 1 hour to obtain a nano-coating for wood surface protection.

[0033] 5) Sealing and filling nano-coatings for wood surface protection must be completed within 1 hour.

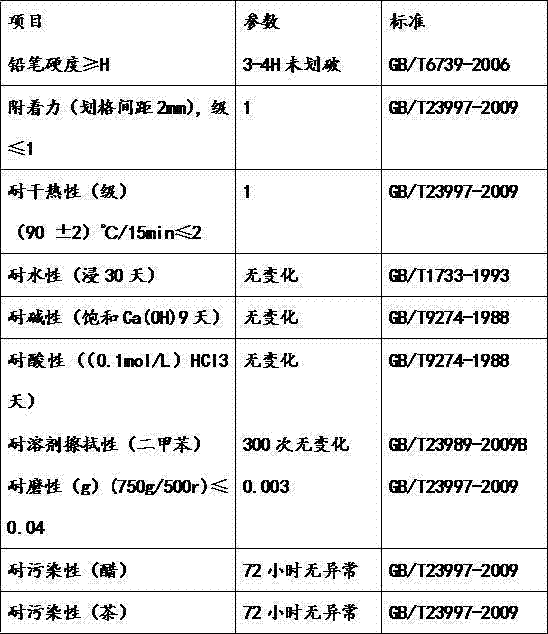

[0034] The prepared wood surface protective nano-coating is used on the surface of wood, and the experimental test index:

[0035]

Embodiment 3

[0037] A kind of technique for preparing wood surface protective nano-coating, this technique comprises the steps:

[0038] 1) Add 26.5Kg of n-butanol into the reaction kettle, then add 27Kg of nano silicon dioxide while stirring, and stir for 30 minutes.

[0039] 2) Add 6.5Kg of butyl acetate and 4.5Kg of ethyl orthosilicate into the reaction kettle, and stir for 1 hour.

[0040] 3) Add 2.5Kg of sodium carboxymethylcellulose and 4.5Kg of silane coupling agent (KH570) into the reaction kettle, and stir for 1 hour.

[0041] 4) Add 16.5Kg of isocyanate and 16.5Kg of polyethylene glycol ether into the reaction kettle, and stir for 1 hour to obtain a nano-coating for wood surface protection.

[0042] 5) Sealing and filling nano-coatings for wood surface protection must be completed within 1 hour.

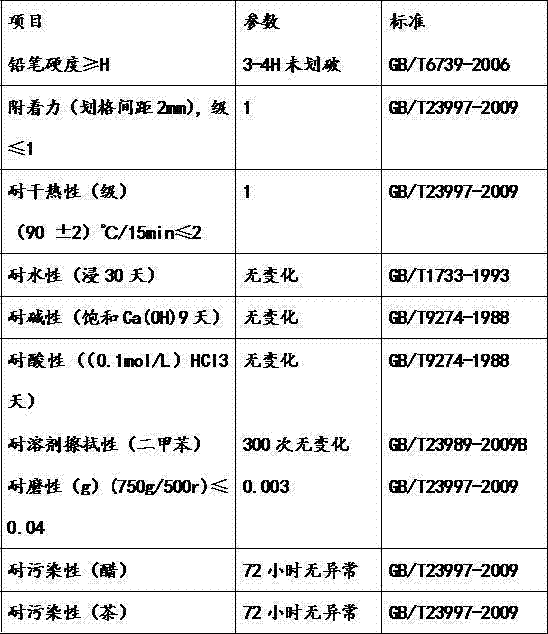

[0043] The prepared wood surface protective nano-coating is used on the surface of wood, and the experimental test index:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com