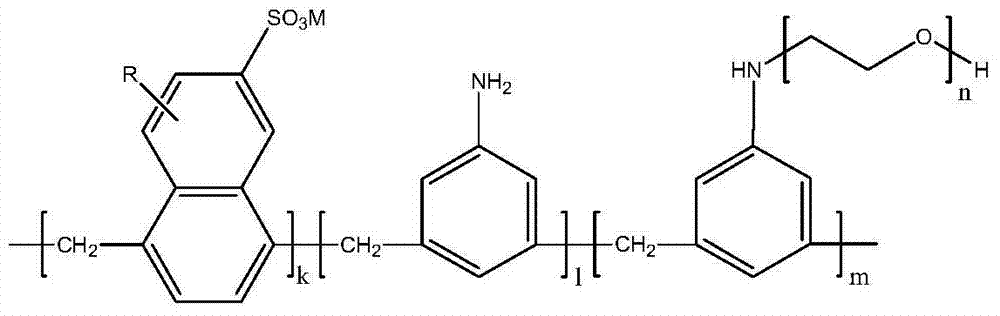

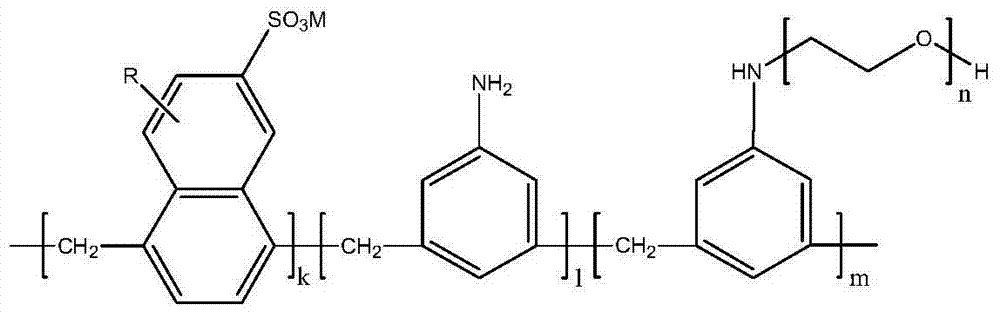

Naphthalene coal water slurry additive and preparation method thereof

A technology for additive preparation and coal water slurry, which is applied in the field of coal water slurry additives, can solve problems such as poor stability of coal slurry, and achieve the effects of long stable period, low price and increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

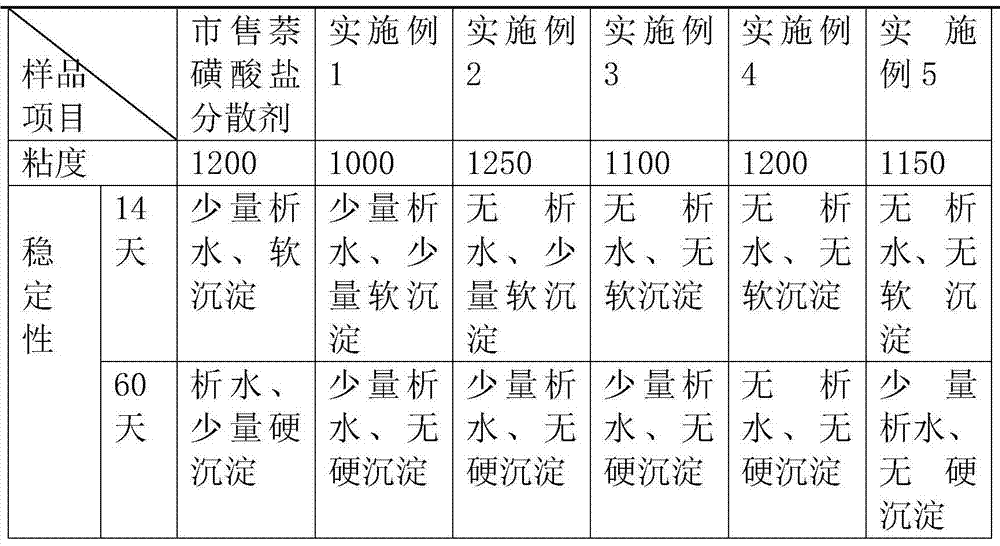

Embodiment 1

[0027] Put 100 grams of C9 / C10 naphthalene-rich fraction in a 500 ml four-neck flask, raise the temperature to 155°C, add 80 grams of 98% concentrated sulfuric acid dropwise, stir at 160-165°C for 3 hours, cool down to 110°C, add 40 mL of water, stirred at constant temperature for 1 hour to obtain naphthalenesulfonic acid solution. At the same time, 10 grams of polyethylene glycol (molecular weight 1000), 1.9 grams of p-toluenesulfonyl chloride and 15 milliliters of heavy aromatics were put into another flask, 0.8 grams of pyridine was added dropwise, stirred at room temperature for 6 hours, then 5 grams of aniline was added, and the mixture was heated at 110 ° C. Stir for 4 hours. Add this reaction solution to the above-mentioned naphthalenesulfonic acid solution, adjust the acidity to 30% with 98% concentrated sulfuric acid, add 50 grams of 38% formaldehyde solution dropwise at 90°C, then raise the temperature to 110°C, stir at constant temperature for 3 hours, and cool down...

Embodiment 2

[0029] Put 100 grams of C9 / C10 naphthalene-rich fraction in a 500 ml four-necked flask, raise the temperature to 155°C, add 90 grams of 98% concentrated sulfuric acid dropwise, stir at 160-165°C for 2 hours, cool down to 110°C, add 40 mL of water, stirred at constant temperature for 1 hour to obtain naphthalenesulfonic acid solution. At the same time, 20 grams of polyethylene glycol (molecular weight 1000), 3.8 grams of p-toluenesulfonyl chloride and 30 milliliters of heavy aromatics were put into another flask, and 1.6 grams of pyridine was added dropwise, stirred at room temperature for 2 hours, then 5 grams of aniline was added, and the °C for 4 hours. Add this reaction solution into the above-mentioned naphthalenesulfonic acid solution, adjust the acidity to 30% with 98% concentrated sulfuric acid, add 70 grams of 38% formaldehyde solution dropwise at 90°C, then raise the temperature to 110°C, stir at constant temperature for 2 hours, and cool down to room temperature , a...

Embodiment 3

[0031] Put 100 grams of C9 / C10 naphthalene-rich fraction in a 500 ml four-neck flask, raise the temperature to 155°C, add 100 grams of 98% concentrated sulfuric acid dropwise, stir at 160-165°C for 4 hours, cool down to 110°C, add 40 mL of water, stirred at constant temperature for 1 hour to obtain naphthalenesulfonic acid solution. At the same time, 10 grams of polyethylene glycol (molecular weight 1000), 1.9 grams of p-toluenesulfonyl chloride and 15 milliliters of heavy aromatics were put into another flask, 0.8 grams of pyridine was added dropwise, stirred at room temperature for 4 hours, and then 10 grams of aniline was added. The reaction was carried out for 4 hours. Add this reaction solution to the above-mentioned naphthalenesulfonic acid solution, adjust the acidity to 30% with 98% concentrated sulfuric acid, add 60 grams of 38% formaldehyde solution dropwise at 90°C, then raise the temperature to 110°C, stir at constant temperature for 3 hours, and cool down to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com