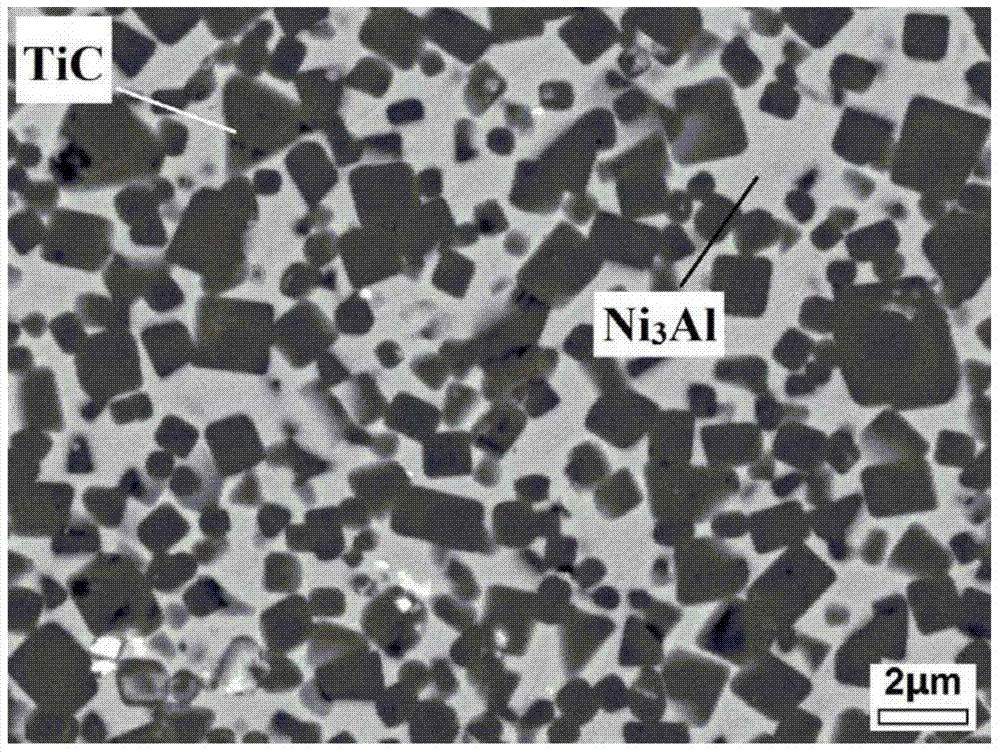

TiC-Ni3Al composite material and preparation method thereof

A composite material and composite powder technology, applied in the field of TiC-Ni3Al composite material and its preparation, can solve the problems of inability to obtain high-density and high-strength TiC-Ni composite material, and achieve the effects of low cost, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

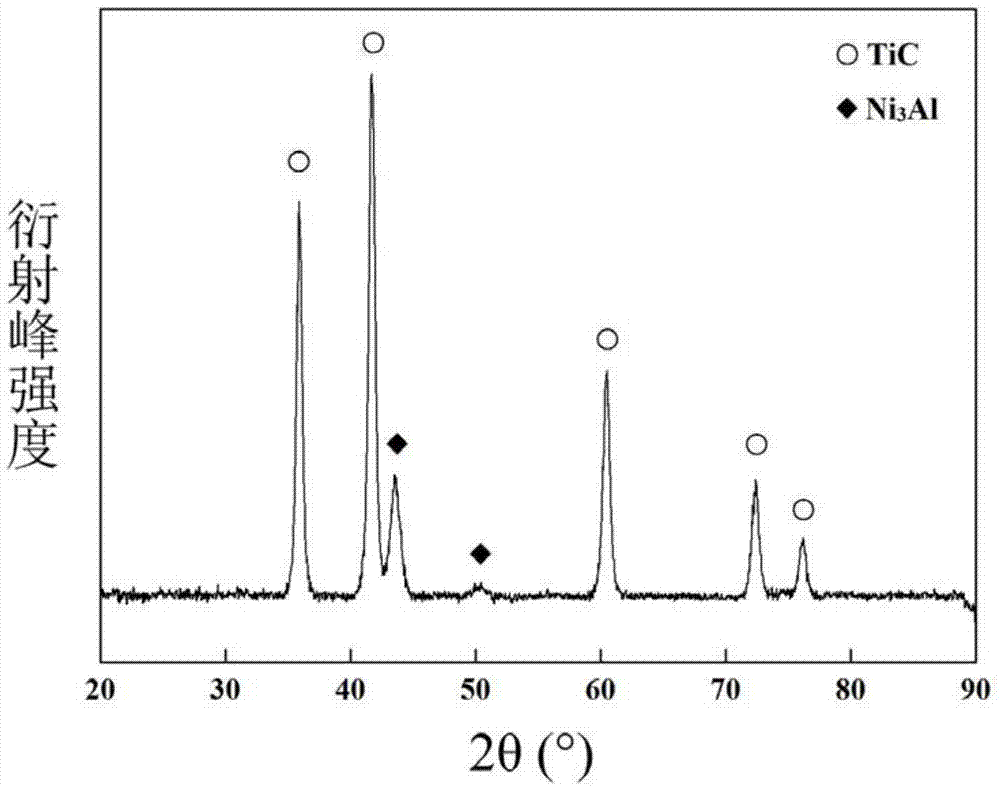

Embodiment 1

[0022] Embodiment 1, comprises the following steps successively:

[0023] (1) Put Ti powder, Ni powder, Al powder, graphite powder, B powder and grinding balls into the ball milling pot, fill with argon, and carry out high-energy ball milling on a planetary ball mill with a ball-to-material mass ratio of 20:1, The ball milling speed is 300rpm, and the ball milling time is 3h, to obtain TiC-Ni 3 The composite powder raw material of Al; Wherein the mass percent of each component is: Ti powder 63.94%, Ni powder 17.50%, aluminum powder 2.53%, graphite powder 15.98%, B powder 0.05%;

[0024] Among them, Ti powder has a particle size of 45 microns and a purity of 99.0%, Ni powder has a particle size of 2.5 microns and a purity of 99.5%, Al powder has a particle size of 2 microns and a purity of 99.5%, and graphite powder has a particle size of 5.5 microns and a purity of 99.5%. 99.5%, B powder has a particle size of 15 microns and a purity of 99.0%;

[0025] (2) The obtained TiC-N...

Embodiment 2

[0028] Embodiment 2, comprises the following steps successively:

[0029](1) Put Ti powder, Ni powder, Al powder, graphite powder, B powder, and balls into a ball mill tank, fill with argon, and perform high-energy ball milling on a planetary ball mill with a ball-to-material mass ratio of 25:1. The rotating speed is 350rpm, and the ball milling time is 4h to obtain TiC-Ni 3 The composite powder raw material of Al; Wherein the mass percent of each component is: Ti powder 55.94%, Ni powder 26.19%, aluminum powder 3.80%, graphite powder 13.99%, B powder 0.08%;

[0030] Among them, Ti powder has a particle size of 25 microns and a purity of 99.2%, Ni powder has a particle size of 2.2 microns and a purity of 99.6%, Al powder has a particle size of 1.8 microns and a purity of 99.6%, and graphite powder has a particle size of 5 microns and a purity of 99.6%. 99.6%, B powder has a particle size of 10 microns and a purity of 99.2%;

[0031] (2) The obtained TiC-Ni 3 Al composite ra...

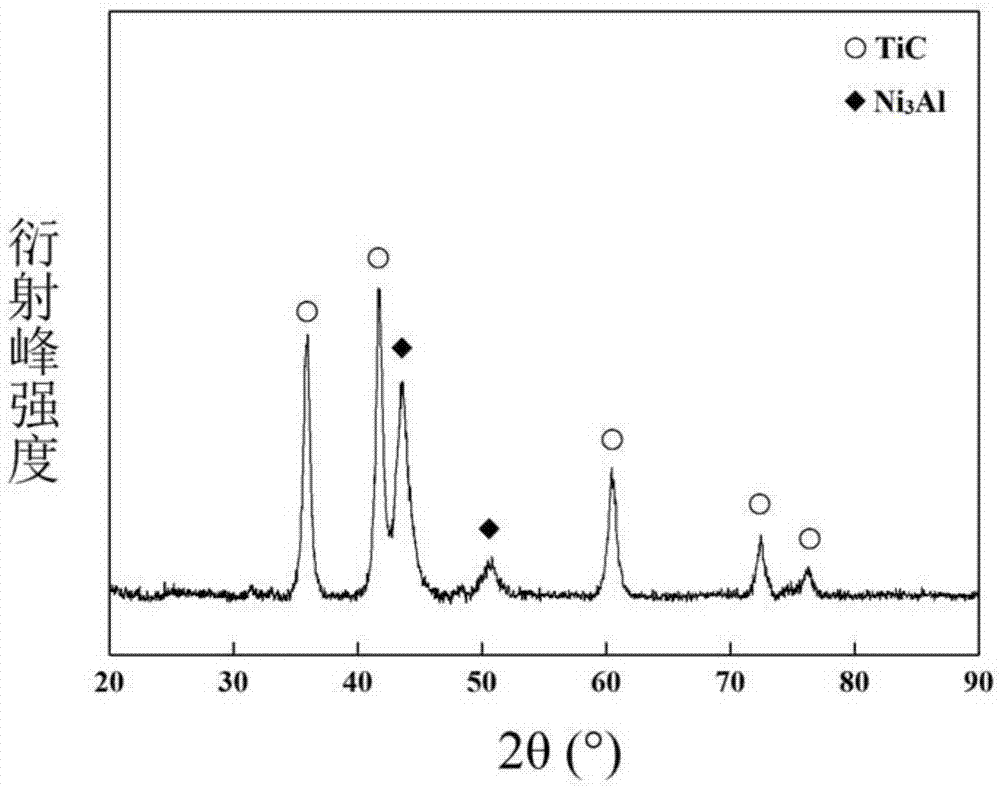

Embodiment 3

[0034] Embodiment 3, comprises the following steps successively:

[0035] (1) Put Ti powder, Ni powder, Al powder, graphite powder, B powder, and balls into a ball mill tank, fill with argon, and perform high-energy ball milling on a planetary ball mill with a mass ratio of ball to material of 30:1. The rotation speed is 350rpm, and the ball milling time is 5h to obtain TiC-Ni 3 The composite powder raw material of Al; Wherein the mass percent of each component is: Ti powder 47.95%, Ni powder 34.89%, aluminum powder 5.07%, graphite powder 11.99%, B powder 0.10%;

[0036] Among them, Ti powder has a particle size of 20 microns and a purity of 99.5%, Ni powder has a particle size of 2 microns and a purity of 99.7%, Al powder has a particle size of 1.5 microns and a purity of 99.7%, and graphite powder has a particle size of 4.5 microns and a purity of 99.7%. 99.7%, B powder has a particle size of 5 microns and a purity of 99.5%;

[0037] (2) The obtained TiC-Ni 3 Al composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com