1*2 high-efficiency reflection-type grating

A high-efficiency, reflective technology, applied in the field of reflective gratings, to achieve the effects of stable grating performance, easy processing and small etching depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

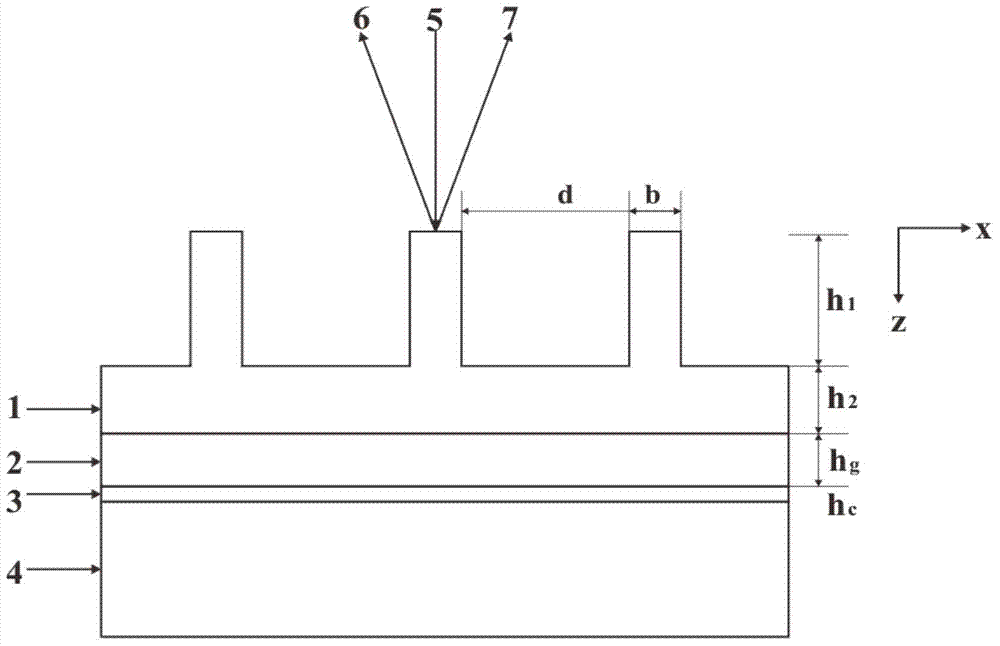

[0015] The central wavelength of the present invention is a 1×2 high-efficiency reflective grating with a TE polarization of 1064 nanometers. Its structure is that a 20-nanometer chromium film 3, a 122-nanometer gold film 2 and a fused silica layer 1 are sequentially coated on a fused silica substrate 4. Layer 1 etches a rectangular groove grating, the unetched fused silica film layer is the connection layer, the grating period is 2304-2308 nm, the duty ratio is 0.34-0.36, the etching depth is 570-590 nm, and the thickness of the connection layer is It is 133-143 nanometers.

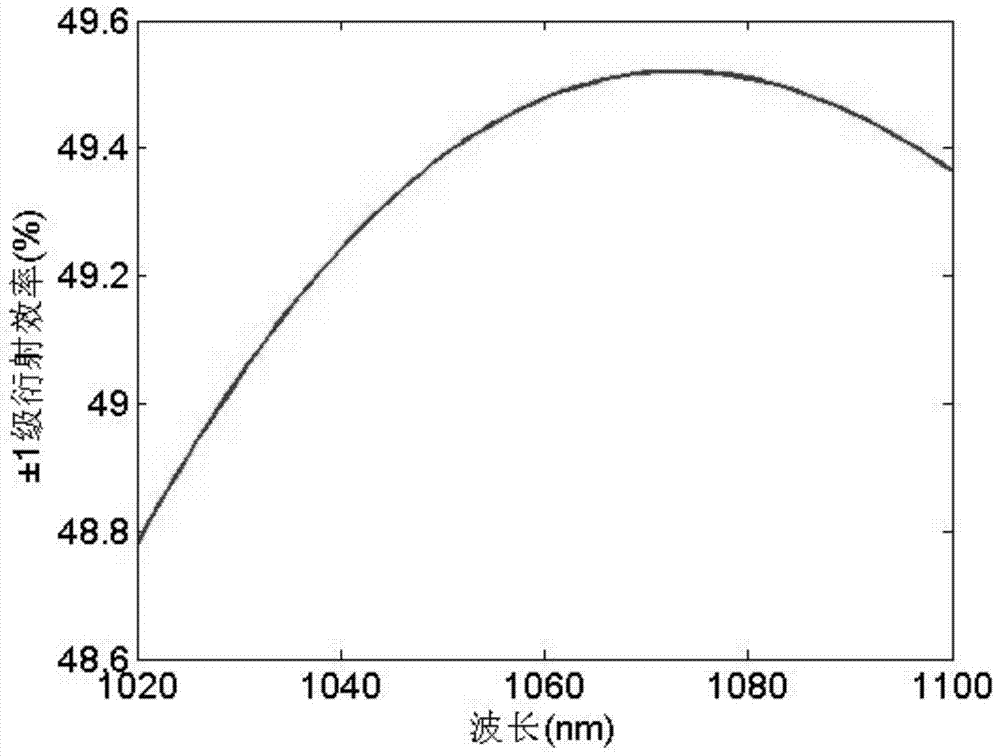

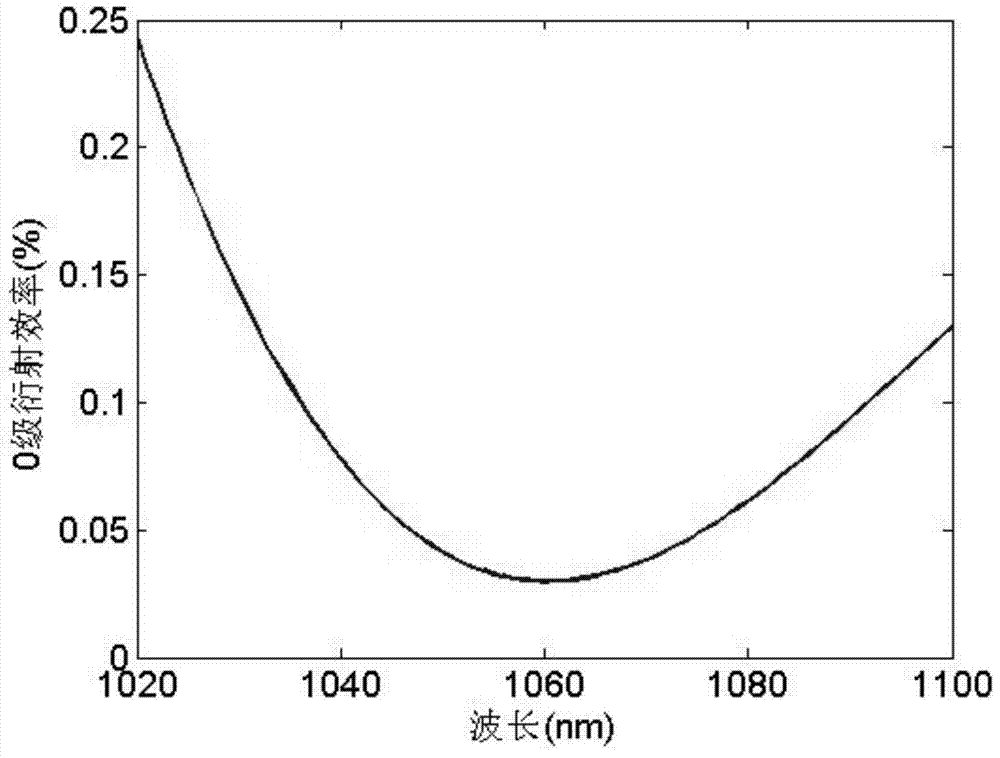

[0016] in such as figure 1 Under the grating structure shown, the present invention calculates the diffraction efficiency of a 1×2 high-efficiency reflective grating in the 1064 nanometer band by using the strict coupled wave theory [Prior Art 2].

[0017] Table 1 provides a series of embodiments of the present invention, in which d is the grating period, f is the grating duty cycle, and h 1 is the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com