Environment-friendly and energy-saving fodder for finishing pigs and preparation method of fodder

An energy-saving and fattening pig technology, applied in animal feed, animal feed, application, etc., can solve the problems that plague the sustainable development of the aquaculture industry, the pollution of feed breeding, and the increase of feed cost, etc., to achieve low cost, reduce feed cost, The effect of saving sources of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

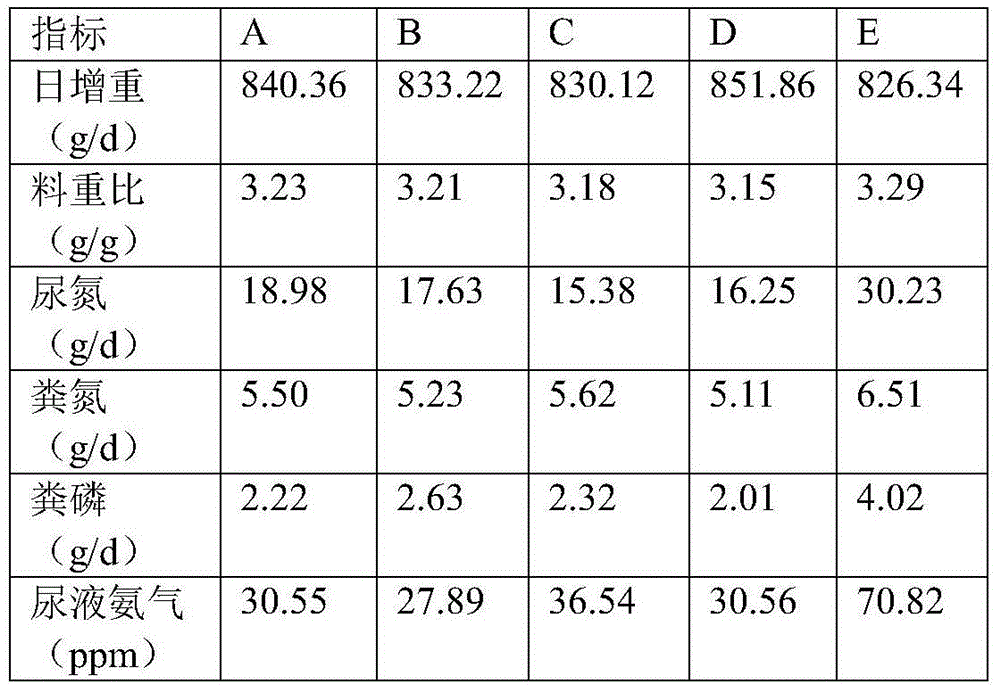

Embodiment 1

[0014] Take 583 kg of corn, 100 kg of secondary flour, 130 kg of canola meal, 140 kg of rice distiller's grains, 3 kg of sodium chloride, 12 kg of stone powder, 0.2 kg of compound multidimensional, 2 kg of compound multimineral, 0.6 kg of choline chloride, Lysine hydrochloride 2.6 kg, phytase 0.1 kg, protease 0.3 kg, cellulase 0.2 kg, montmorillonite 2 kg, other zeolite powder. Weigh various raw materials according to the proportion for later use; crush corn, canola meal, and distiller's grains and mix them with secondary powder; mix multidimensional, multimineral, choline chloride, lysine hydrochloride, phytase, Protease, cellulase, sodium chloride, stone powder, and montmorillonite are mixed evenly; then the above-mentioned mixture is sent to a mixer, mixed thoroughly and sent to a modulator, and granulated by a granulator, then cooled, then classified, and finally Bagging is the finished product A.

Embodiment 2

[0016] Take 555 kg of corn, 150 kg of secondary flour, 150 kg of canola meal, 120 kg of rice distiller's grains, 2 kg of sodium chloride, 10 kg of stone powder, 0.18 kg of compound multidimensional, 1.5 kg of compound multimineral, 0.5 kg of choline chloride, Lysine hydrochloride 2.2 kg, phytase 0.15 kg, protease 0.4 kg, cellulase 0.3 kg, montmorillonite 3 kg, other zeolite powder. Weigh various raw materials according to the proportion for later use; crush corn, canola meal, and distiller's grains and mix them with secondary powder; mix multidimensional, multimineral, choline chloride, lysine hydrochloride, phytase, Protease, cellulase, sodium chloride, stone powder, and montmorillonite are mixed evenly; then the above-mentioned mixture is sent to a mixer, mixed thoroughly and sent to a modulator, and granulated by a granulator, then cooled, then classified, and finally Bagging is the finished product B.

Embodiment 3

[0018] Take 550 kg of corn, 120 kg of secondary flour, 200 kg of canola meal, 100 kg of rice distiller's grains, 2.5 kg of sodium chloride, 10 kg of stone powder, 0.15 kg of compound multidimensional, 1.0 kg of compound multimineral, 0.4 kg of choline chloride, Lysine hydrochloride 3.0 kg, phytase 0.15 kg, protease 0.5 kg, cellulase 0.4 kg, montmorillonite 5 kg, other zeolite powder. Weigh various raw materials according to the proportion for later use; crush corn, canola meal, and distiller's grains and mix them with secondary powder; mix multidimensional, multimineral, choline chloride, lysine hydrochloride, phytase, Protease, cellulase, sodium chloride, stone powder, and montmorillonite are mixed evenly; then the above-mentioned mixture is sent to a mixer, mixed thoroughly and sent to a modulator, and granulated by a granulator, then cooled, then classified, and finally Bagging is the finished product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com