Honeycomb active carbon supported catalyst plate

A technology of supporting catalyst and activated carbon, which is applied in the field of photocatalytic materials, can solve the problems of complex pollutant composition, large fluctuation, and the photocatalytic reaction efficiency cannot be guaranteed, and achieves high catalytic degradation efficiency of organic matter, simple manufacturing method, and promotion of electrons. the effect of the transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

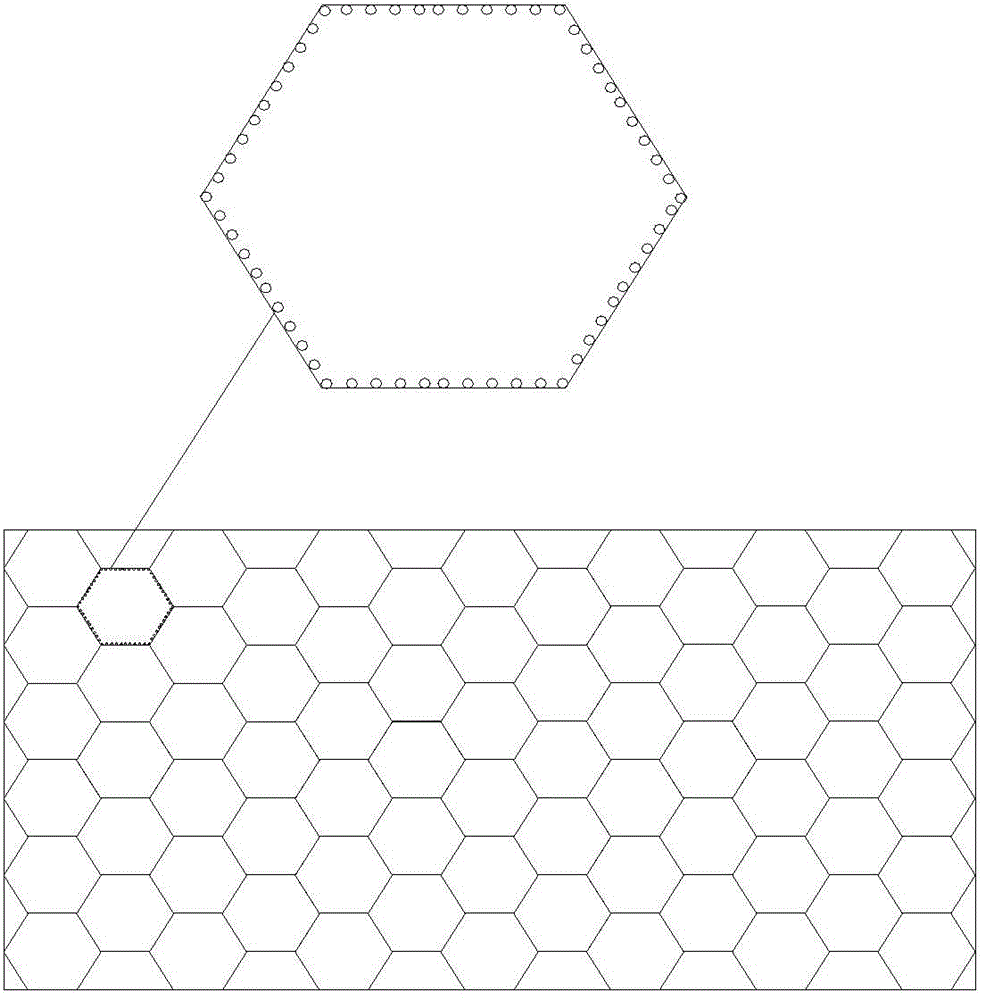

Image

Examples

Embodiment 1

[0044] A honeycomb-type activated carbon-supported catalyst plate. Aluminum honeycomb is selected as the photocatalyst support material. The surface of the aluminum honeycomb is coated with two layers of activated carbon as the photocatalyst carrier. The photocatalyst is sprayed on the surface of the activated carbon, and the photocatalyst loading is 1% of the mass of the activated carbon. .

[0045] The method for preparing a honeycomb active carbon-supported catalyst plate, the specific preparation method is as follows:

[0046] 1. Preparation of Activated Carbon Aluminum Honeycomb Support

[0047] 1) Preparation of activated carbon suspension: take 100mL of deionized water with a pH of 5, add sodium hexametaphosphate, stir to dissolve, add activated carbon powder, stir and sonicate for 0.1 hour to become an activated carbon suspension with a concentration of 0.01g / L;

[0048] And the mass ratio of sodium hexametaphosphate to activated carbon powder is 1:100;

[0049] 2) U...

Embodiment 2

[0060] A honeycomb activated carbon-supported catalyst plate, using aluminum honeycomb as the photocatalyst support material, the surface of the aluminum honeycomb is coated with 5 layers of activated carbon as the photocatalyst carrier, and then spraying the photocatalyst on the surface of the activated carbon, and the photocatalyst loading is 40% of the mass of the activated carbon .

[0061] The method for preparing a honeycomb active carbon-supported catalyst plate, the specific preparation method is as follows:

[0062] 1). Preparation of activated carbon aluminum honeycomb carrier

[0063] 1) Preparation of activated carbon suspension: take 10 L of deionized water with a pH of 12, add sodium dodecyl sulfonate, stir to dissolve, add activated carbon powder, stir and ultrasonic for 4 hours to become activated carbon suspension, the concentration of the suspension is 40g / L ;

[0064] And the mass ratio of sodium dodecyl sulfonate and activated carbon powder is 1:20;

[0...

Embodiment 3

[0076] A honeycomb-type activated carbon-supported catalyst plate, using aluminum honeycomb as the photocatalyst support material, the surface of the aluminum honeycomb is coated with 3 layers of activated carbon as the photocatalyst carrier, and then spraying the photocatalyst on the surface of the activated carbon, and the photocatalyst loading is 20% of the mass of the activated carbon .

[0077] The method for preparing a honeycomb active carbon-supported catalyst plate, the specific preparation method is as follows:

[0078] 1. Preparation of Activated Carbon Aluminum Honeycomb Support

[0079] 1) Preparation of activated carbon suspension: take 5 L of deionized water with a pH of 7, add cysteine, stir and dissolve, add activated carbon powder, stir and ultrasonic for 2 hours to become activated carbon suspension, the concentration of the suspension is 10g / L;

[0080] And the mass ratio of cysteine and activated carbon powder is 1:60;

[0081] 2) Using the aluminum ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com