Advanced treatment method for heavy metal sewage of refuse landfill

A landfill and advanced treatment technology, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve heavy metal content reduction, suspended solids, high turbidity, high salt content, etc. problem, to achieve the effect of strong adsorption capacity and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

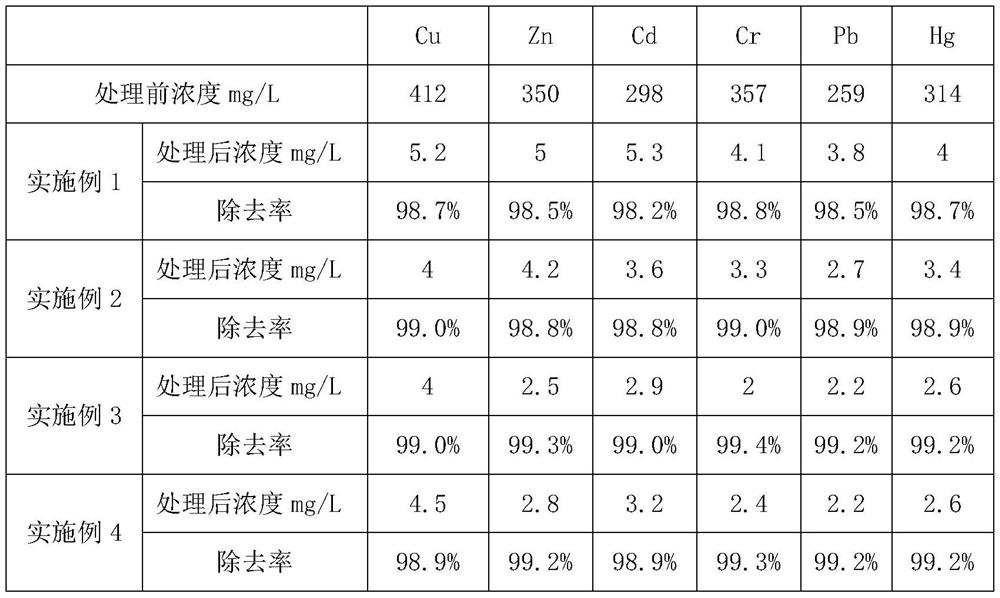

Examples

Embodiment 1

[0025] A method for advanced treatment of heavy metal sewage in a landfill, comprising the following steps:

[0026] (1) Pretreatment: The garbage in the landfill is first sorted and filtered by the garbage sorting machine, the remaining residue is extruded by the extruder to extrude water, and then the extruded material and sediment are removed by the filter device, and the remaining wastewater is passed through Into the regulating tank, take 1L of waste water, measure the content of various heavy metals, and calculate the total content of heavy metals;

[0027] (2) PH value adjustment: add 20 parts of sodium hydroxide in the adjustment tank, adjust the pH to 10, add a remover in the reaction tank, the dosage is 10 times the total content of heavy metals, and stir for 20min, wherein the remover is hexane 7 parts of diamine; 1 part of sewage aluminum sulfate, 3 parts of carbon disulfide, 2 parts of sodium hydroxide, 0.1 part of magnesium oxide, and 44 parts of water;

[0028]...

Embodiment 2

[0034] A method for advanced treatment of heavy metal sewage in a landfill, comprising the following steps:

[0035] (1) Pretreatment: The garbage in the landfill is first sorted and filtered by the garbage sorting machine, the remaining residue is extruded by the extruder to extrude water, and then the extruded material and sediment are removed by the filter device, and the remaining wastewater is passed through Into the regulating tank, take 1L of waste water, measure the content of various heavy metals, and calculate the total content of heavy metals;

[0036] (2) PH value adjustment: add 25 parts of sodium hydroxide and sulfuric acid in the adjustment tank, adjust the pH to 10, add a remover in the reaction tank, the dosage is 15 times the total content of heavy metals, and stir for 40min, wherein the remover 10 parts of hexanediamine; 2 parts of sewage aluminum sulfate, 8 parts of carbon disulfide, 2 parts of sodium hydroxide, 0.2 parts of magnesium oxide, and 55 parts of...

Embodiment 3

[0043] A method for advanced treatment of heavy metal sewage in a landfill, comprising the following steps:

[0044] (1) Pretreatment: The garbage in the landfill is first sorted and filtered by the garbage sorting machine, the remaining residue is extruded by the extruder to extrude water, and then the extruded material and sediment are removed by the filter device, and the remaining wastewater is passed through Into the regulating tank, take 1L of waste water, measure the content of various heavy metals, and calculate the total content of heavy metals;

[0045] (2) PH value adjustment: add 25 parts of sodium hydroxide in the adjustment tank, adjust the pH to 11, add a remover in the reaction tank, the dosage is 15 times the total content of heavy metals, and stir for 45min, wherein, the remover is hexane 10 parts of diamine; 3 parts of sewage aluminum sulfate, 10 parts of carbon disulfide, 2 parts of sodium hydroxide, 0.3 parts of magnesium oxide, 60 parts of water;

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com