Hydrolysis hydrogen production agent

A technology for hydrogen production and water absorbing agent by hydrolysis, applied in the production of hydrogen and other directions, can solve the problems of slow reaction rate and low hydrogen production, and achieve the effects of reducing cost, improving volumetric energy density, and reducing the weight of hydrogen production formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

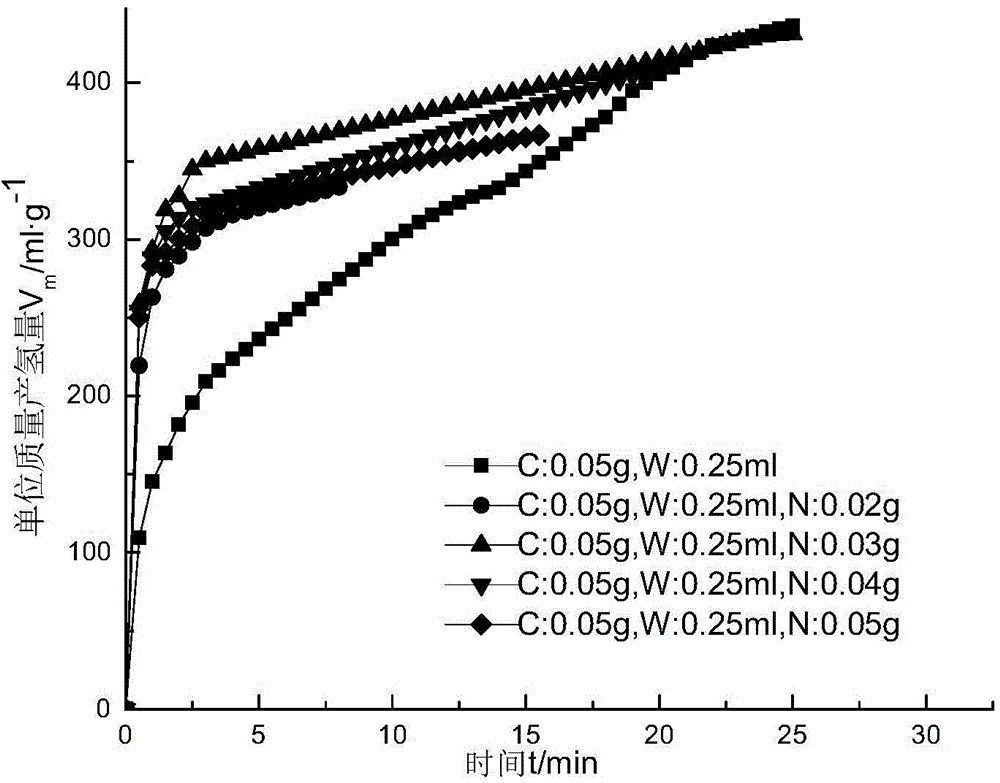

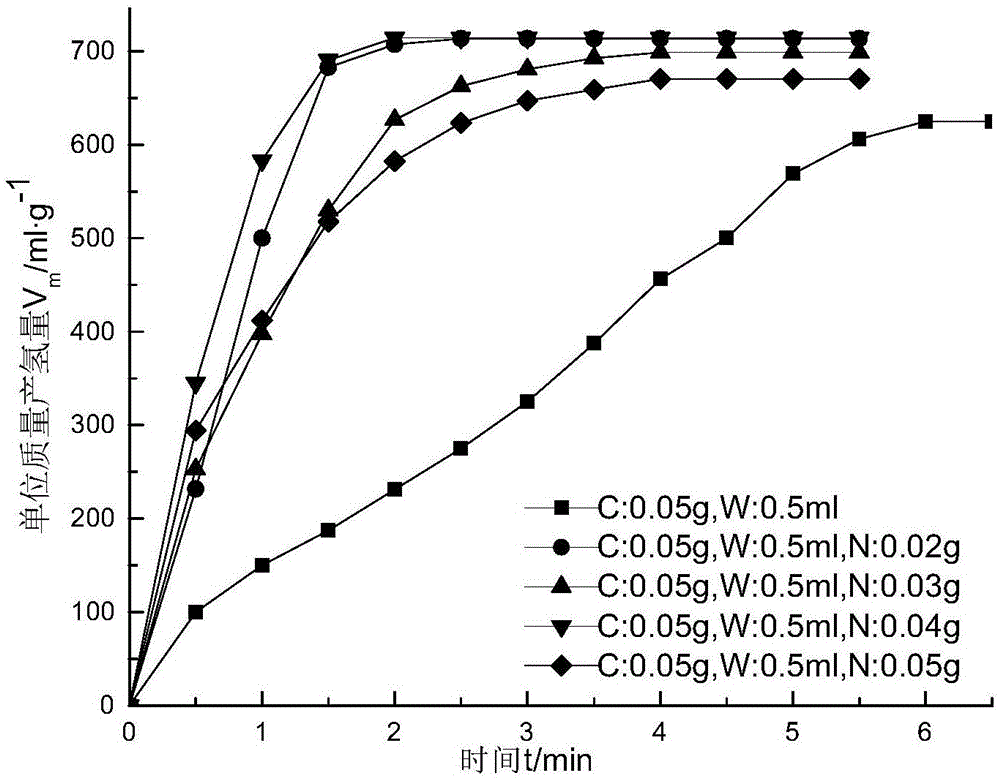

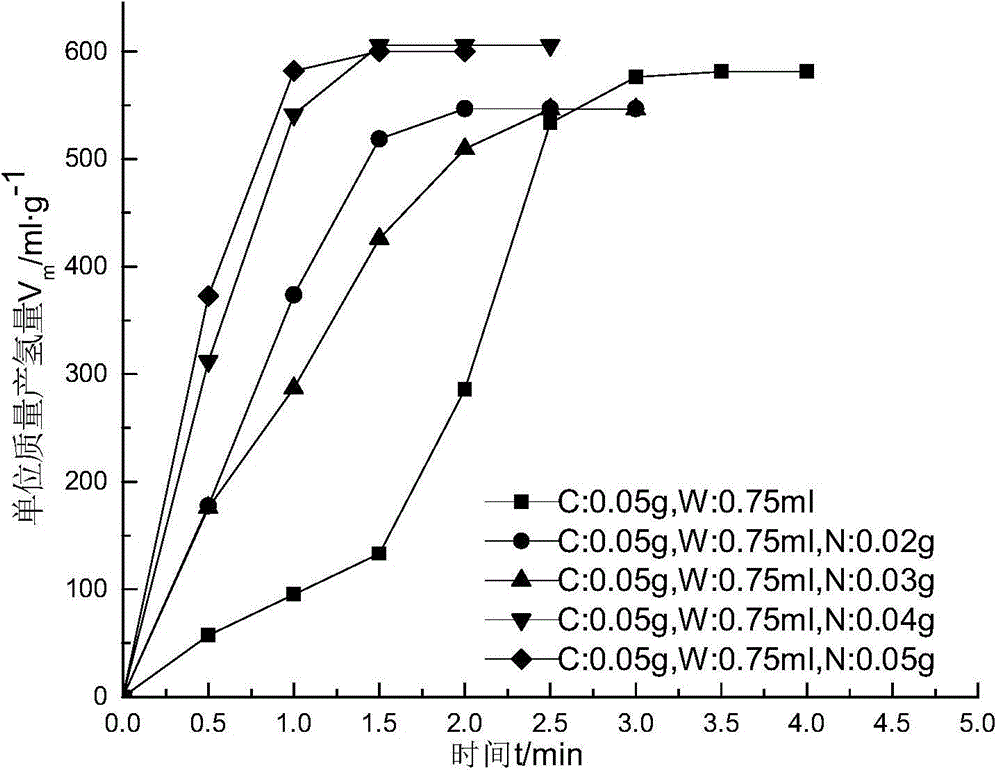

[0028] Mix 0.25g of sodium borohydride powder, 0.05g of cobalt chloride, and citric acid of different qualities in a 50mL round-bottomed flask, and add 0.25mL, 0.5mL, and 0.75mL of distilled water into the flask with a 1mL injection needle. The reaction was carried out in a round-bottom flask, and the generated hydrogen gas was led out through a rubber tube to a 1L measuring cylinder filled with water and turned upside down into a large beaker, so as to record the amount of hydrogen gas generated collected at a certain time interval. The reaction is at room temperature 18 °C, NaBH 4 The dosage is 0.25g, and the water inlet method is selected under the condition of one-time injection. Hydrogen production per unit mass Vm (mL / g) and time t (min) are as attached Figure 1~Figure 3 Shown (in the legend, W represents the amount of water added, N represents citric acid, and C represents cobalt chloride).

experiment example 2

[0030] Mix 0.25g of sodium borohydride powder, 0.03g of cobalt chloride, and citric acid of different qualities in a 50mL round-bottomed flask, and then add 0.5mL of distilled water into the round-bottomed flask with a 1mL injection needle for reaction. The generated hydrogen gas is led out through a rubber tube into a 1L measuring cylinder filled with water and turned upside down into a large beaker, so as to record the amount of generated hydrogen gas collected at a certain time interval. The reaction is at room temperature 18 °C, NaBH 4 The dosage is 0.25g, and the water inlet method is selected under the condition of one-time injection. Hydrogen production per unit mass Vm (mL / g) and time t (min) are as attached Figure 4 Shown (in the legend, W represents the amount of water added, N represents citric acid, and C represents cobalt chloride).

[0031] From the above two experimental examples, the optimal ratio obtained is sodium borohydride:cobalt chloride:citric acid=0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com