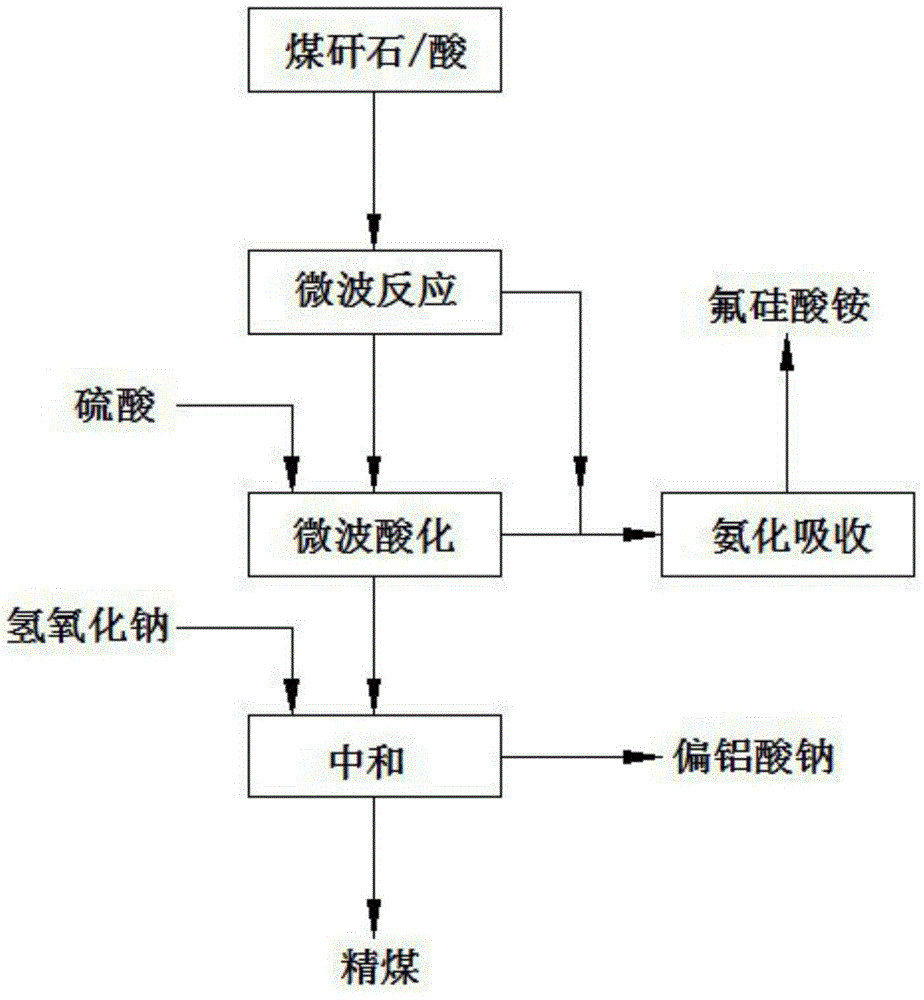

Method for preparing clean coal, ammonium fluorosilicate byproduct and sodium metaaluminate product from coal gangue

A technology of ammonium fluorosilicate and sodium metaaluminate, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, the petroleum industry, silicon halide compounds, etc., can solve problems such as ecological damage and environmental pollution, and achieve Effects of reduced reaction energy consumption, shortened process flow, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Crush the coal gangue to 80 mesh and the additive fluosilicic acid with a concentration of 15% according to the mass volume of 1t: 1.5m 3 The ratio is mixed, placed in a microwave reactor to control the temperature of the material at 90°C, the microwave power is 2kw, and the microwave frequency is 200MHz for the reaction. The reaction time is 20min. After the reaction, the solid and liquid are separated to obtain the solid a. 50% sulfuric acid is 1t according to mass volume: 0.2m 3 The ratio of microwave acidification reaction is carried out, the acidification temperature is controlled at 150°C, the microwave power is 2kw, the microwave frequency is 300MHz, and the acidification reaction time is 20min to obtain solid b. The gas produced by microwave reaction and microwave acidification passes through the ammoniated absorption tower to obtain fluorine For ammonium silicate products, solid b and sodium hydroxide with a concentration of 10% are 1t:1m according to the mass ...

Embodiment 2

[0022] Crush the coal gangue to 80 mesh and the additive fluosilicic acid with a concentration of 15% according to the mass volume of 1t: 1.5m 3 The ratio is mixed, placed in a microwave reactor to control the temperature of the material at 90 ° C, the microwave power is 5kw, and the microwave frequency is 1000MHz for the reaction. The reaction time is 20 minutes. After the reaction, the solid and liquid are separated to obtain the solid a. 70% sulfuric acid is 1t according to mass volume: 0.7m 3 The ratio of microwave acidification reaction is carried out, the acidification temperature is controlled at 150°C, the microwave power is 5kw, the microwave frequency is 915MHz, the acidification reaction time is 30min, and the solid b is obtained. The gas produced by microwave reaction and microwave acidification passes through the ammoniated absorption tower to obtain fluorine For ammonium silicate product, the solid b and the sodium hydroxide with a concentration of 20% are 1t:4m ...

Embodiment 3

[0024] Crush the coal gangue to 100 mesh and add the auxiliary agent fluosilicic acid with a concentration of 25% according to the mass volume of 1t: 1m 3 The ratio is mixed, placed in a microwave reactor to control the temperature of the material at 100 ° C, the microwave power is 10kw, and the microwave frequency is 2500MHz for the reaction. The reaction time is 30 minutes. After the reaction, the solid and liquid are separated to obtain the solid a. 80% sulfuric acid is 1t according to the mass volume: 0.6m 3 The ratio of microwave acidification reaction is carried out, the acidification temperature is controlled at 200°C, the microwave power is 10kw, the microwave frequency is 2450MHz, the acidification reaction time is 30min, and the solid b is obtained. The gas produced by microwave reaction and microwave acidification passes through the ammoniated absorption tower to obtain fluorine For ammonium silicate product, solid b and sodium hydroxide with a concentration of 25% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com