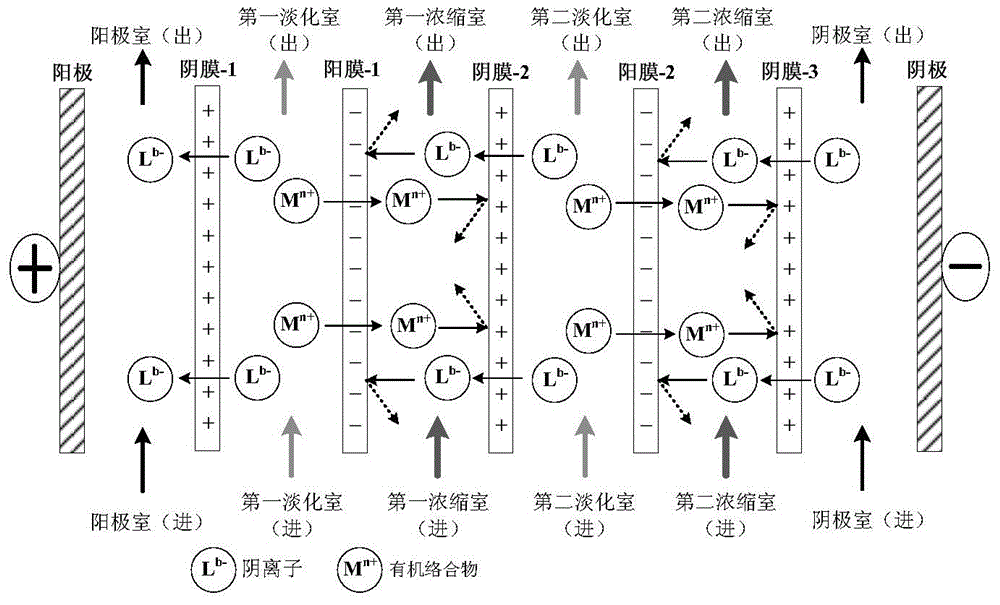

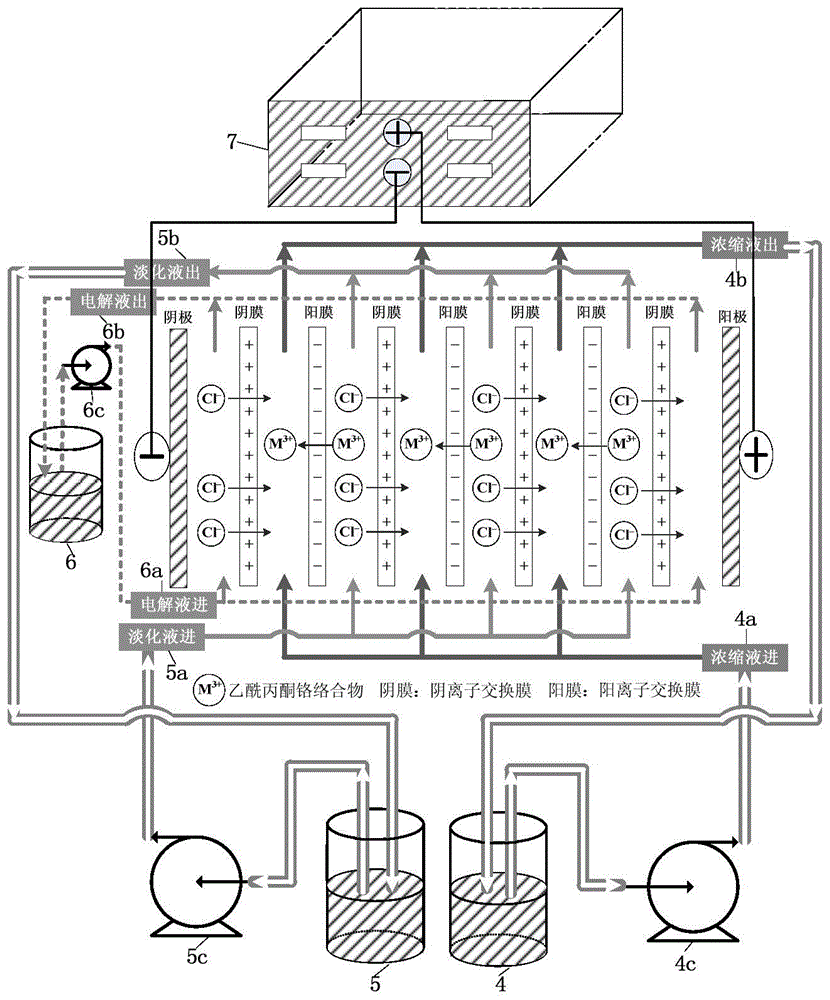

Electric extraction process for simultaneously and efficiently extracting and recycling metal elements and functional organic compounds

A technology of organic compounds and metal elements, which is applied in the field of electro-extraction technology, can solve the problems of high operating cost, expensive ion exchange resin, and large environmental pollution, and achieve the effect of avoiding high energy consumption, easy membrane pollution, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

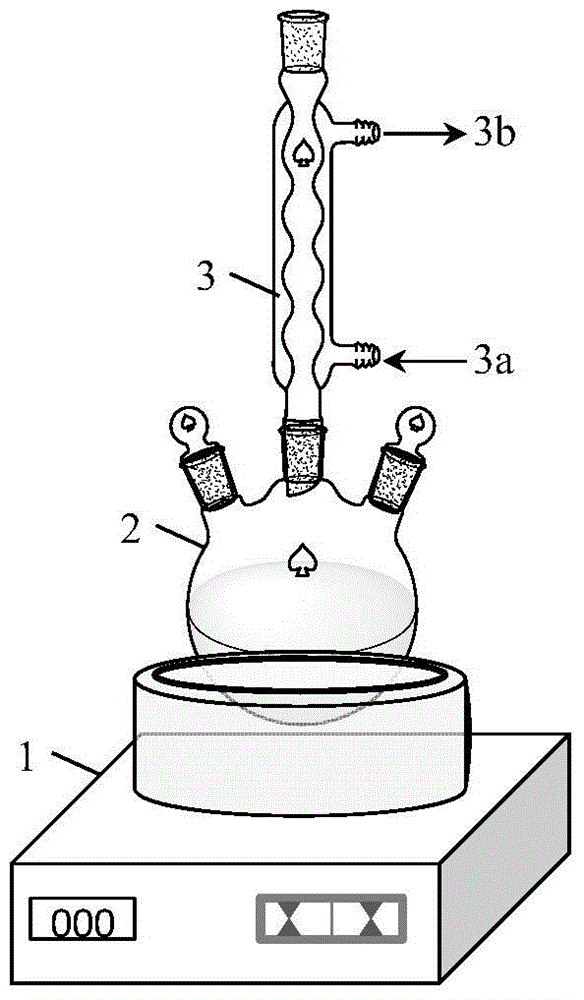

[0042] The present embodiment carries out the simultaneous treatment of acetylacetone wastewater and metal ion wastewater through the following steps:

[0043] 1. The mixed reaction of acetylacetone wastewater and metal ion wastewater prepares chromium acetylacetonate solution:

[0044] The simulated acetylacetone wastewater used in this example contains 5 g / L of acetylacetone, the simulated metal ion wastewater is simulated chromium ion wastewater, and the concentration of chromium ions is 13.32 g / L.

[0045] Wherein the simulated acetylacetone wastewater is prepared as follows: take 400mL of 95% ethanol, then add 4.1mL of 99% acetylacetone to it, and stir for 5 minutes, so that the acetylacetone, ethanol and deionized water are completely mixed to obtain the acetylacetone simulated wastewater.

[0046] The simulated chromium ion wastewater was prepared as follows: take 10.656g of chromium chloride in 400ml deionized water, stir for 5 minutes to completely dissolve the chromi...

Embodiment 2

[0062] The present embodiment carries out the simultaneous treatment of acetylacetone wastewater and metal ion wastewater through the following steps:

[0063] 1. The mixed reaction of acetylacetone wastewater and metal ion wastewater prepares chromium acetylacetonate solution:

[0064] The simulated acetylacetone wastewater used in this example contains 10 g / L of acetylacetone, and the simulated metal ion wastewater is chromium ion wastewater, wherein the concentration of chromium ions is 13.32 g / L.

[0065] Wherein the simulated acetylacetone wastewater is prepared as follows: take 400mL of 95% ethanol, then add 8.2mL of 99% acetylacetone to it, and stir for 5 minutes, so that the acetylacetone, ethanol and deionized water are completely mixed to obtain the acetylacetone simulated wastewater.

[0066] The simulated chromium ion wastewater was prepared as follows: take 10.656g of chromium chloride in 400ml deionized water, stir for 5 minutes to completely dissolve the chromiu...

Embodiment 3

[0081] The mixed reaction of acetylacetone wastewater and metal ion wastewater prepares chromium acetylacetonate mixed solution:

[0082] The simulated acetylacetone wastewater used in this example contains 15 g / L of acetylacetone, and the simulated metal ion wastewater is chromium ion wastewater, wherein the concentration of chromium ions is 13.32 g / L.

[0083] Wherein the simulated acetylacetone wastewater was prepared as follows: 400mL of 95% ethanol was taken, then 12.3mL of 99% acetylacetone was added thereto, and stirred for 5 minutes, so that the acetylacetone, ethanol and deionized water were mixed completely to obtain the acetylacetone simulated wastewater.

[0084] The simulated chromium ion wastewater was prepared as follows: take 10.656g of chromium chloride in 400ml deionized water, stir for 5 minutes to completely dissolve the chromium chloride, and obtain simulated chromium ion wastewater.

[0085] In this embodiment, chromium ion and acetylacetone are complexed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com