A kind of recovery method of simultaneous nitrification anammox and denitrification process

A nitrosated anammox and anaerobic ammonium oxidation technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the collapse of SNAD process and the removal rate of total nitrogen drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

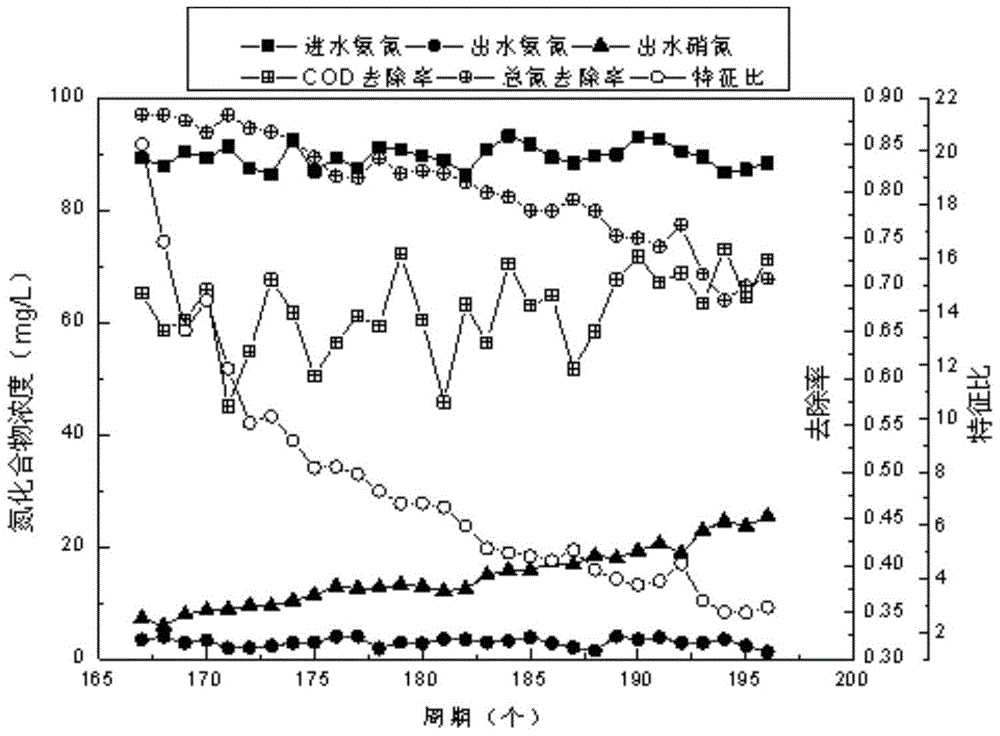

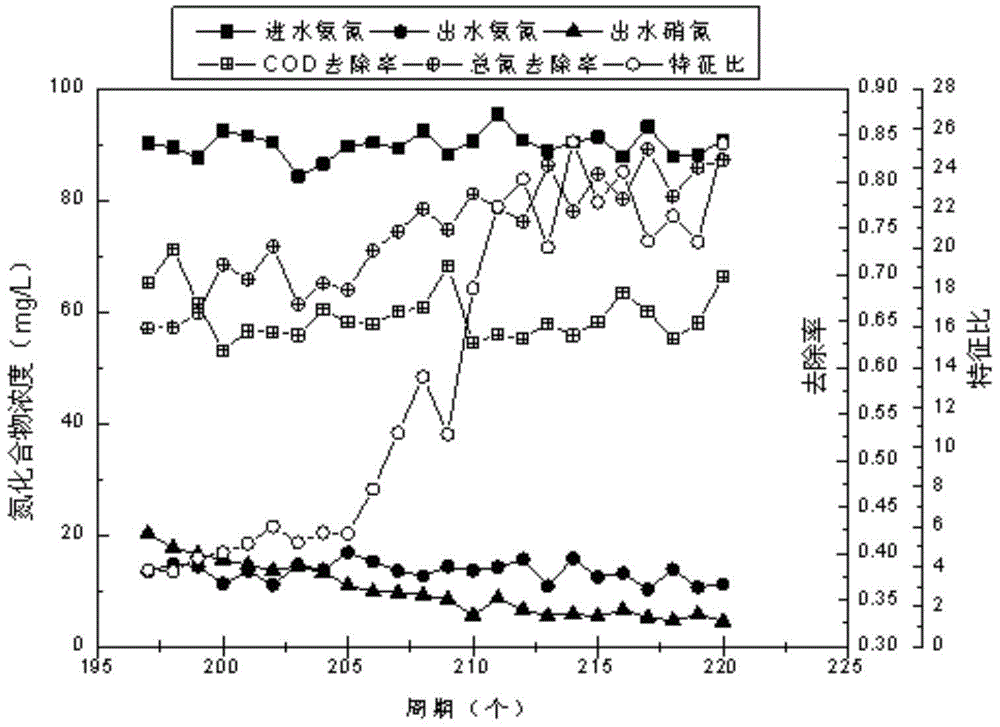

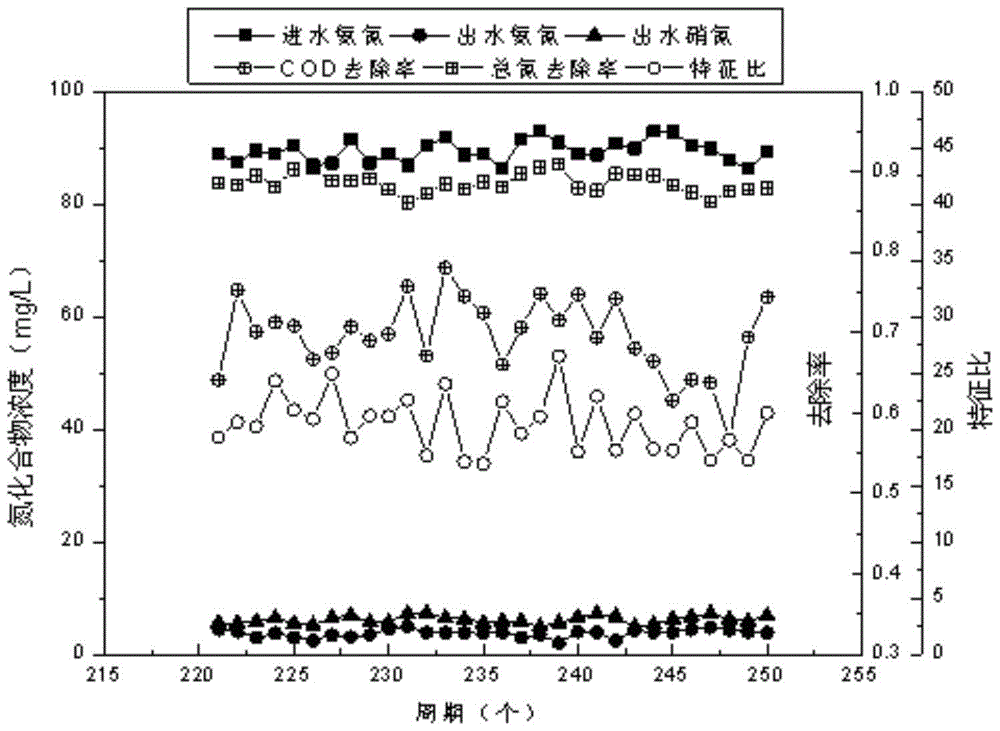

[0017] This experiment adopts SBR reactor, which is made of plexiglass, and a circulating water bath system is installed outside to maintain the temperature in the reactor (28-32°C). The inner diameter of the reactor is 9cm, the height is 1000cm, the effective volume is 5.4L, The exchange ratio is 50%, the bottom is equipped with an aeration head, and the dissolved oxygen is regulated and controlled through a rotameter and an online dissolved oxygen analyzer. The reactor is equipped with a simple automatic control device to realize the continuous automatic operation of water intake, reaction, precipitation, drainage, idle and other stages. The experiment is based on the septic output of a community: NH 4 + -N=90±5mg / L, COD=160±25mg / L, pH=7.3±0.1, alkalinity=370±50gCaCO 3 . Runs 2 cycles per day. Determination of NH in influent and effluent water respectively every cycle 4 + -N, NO 2 — N. NO 3 — N content, and calculate the total nitrogen removal rate and characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com