Treatment method for gold-smelting cyanide-containing wastewater

A treatment method and technology for cyanide wastewater, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem that the consumption operation control parameters are difficult to determine, it is difficult to stably reach the standard, and the final effluent is difficult to be determined. It is difficult to reach the standard stably, and achieve the effect of saving the cost of auxiliary materials, low cost, and reducing the content of cyanide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

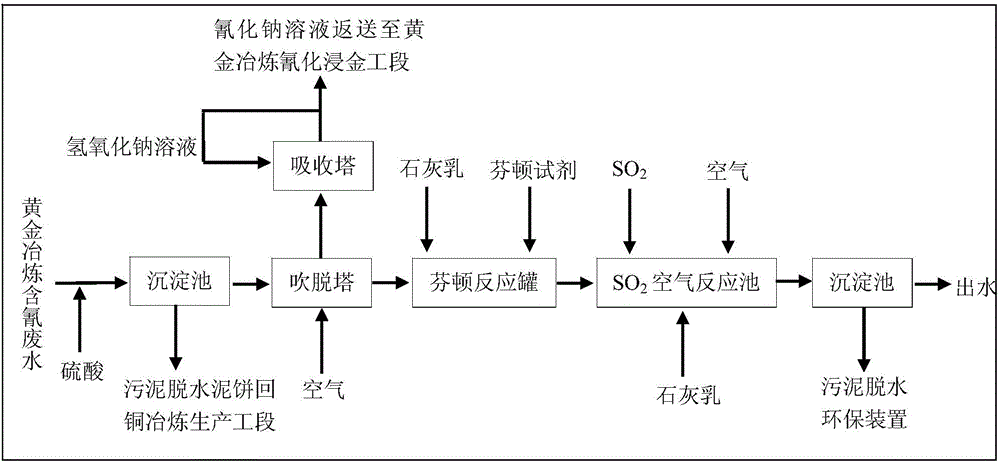

[0039] A treatment method of gold smelting cyanide-containing waste water of the present invention, the total cyanide content of this cyanide-containing waste water is 1100mg / L, initial COD Cr The concentration is 413.5mg / L. Such as figure 1 As shown, the processing method includes the following steps:

[0040](1) Acidification reaction: first add industrial sulfuric acid with a mass concentration of 93% to gold smelting cyanide-containing wastewater, adjust the pH value of cyanide-containing wastewater to 2, and acidification reaction occurs. After separation, acidified wastewater and copper-cyanide complexes are obtained, and the copper-cyanide complexes (ie sludge dewatered cakes) can be returned to the copper smelting production section to recover copper.

[0041] (2) stripping treatment: the acidified waste water is sent to the stripping tower, then air is blown into the stripping tower to carry out the stripping treatment, and the cyanogen-containing gas produced by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com