Deep-well aeration tank, enhanced wastewater nitrogen and phosphorus removal device and enhanced wastewater nitrogen and phosphorus removal method

A deep well aeration, nitrogen and phosphorus removal technology, applied in chemical instruments and methods, degassed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as inconvenience to people's lives, impracticability, and difficulty in operation and maintenance , to achieve the effects of small footprint, reduced interference, and carbon saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

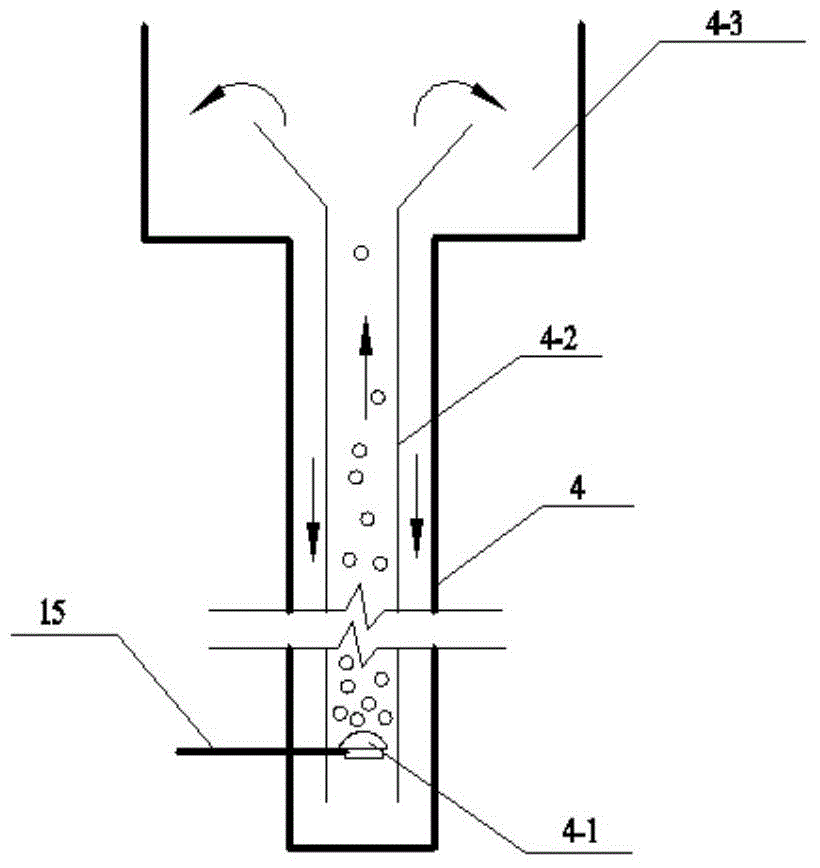

[0027] Specific implementation mode one: combine figure 1 Describe this embodiment, the deep well aeration tank in this embodiment includes the outer cylinder body of the deep well aeration tank, the inner tube 4-2 of the deep well aeration tank, the degassing tank 4-3, the aeration device 4-1 and the intake pipe 15, and its characteristics The water inlet of the deep well aeration tank and the aeration device 4-1 are all arranged at the inner bottom of the inner cylinder 4-2 of the aeration tank, and the air inlet pipe 15 communicates with the aeration device 4-1.

specific Embodiment approach 2

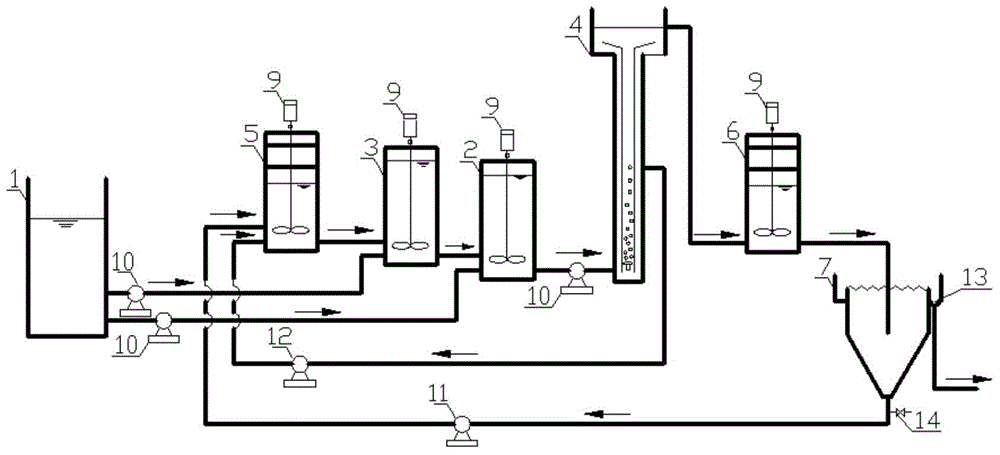

[0028] Specific implementation mode two: combination figure 2 Illustrate this embodiment, the waste water enhanced denitrification and dephosphorization device of this embodiment comprises water storage tank 1, anaerobic pond 2, anoxic pond 3, deep well aeration pond 4, first degassing pond 5, second degassing pond 6, Secondary settling tank 7, water inlet pump 10, sludge return pump 11, nitrification liquid return pump 12, drain port 13 and sludge discharge valve 14;

[0029] The anaerobic pool 2, the anoxic pool 3, the first degassing pool 5 and the second degassing pool 6 are equipped with agitators 9; the water storage tank 1 is connected with the anaerobic pool 2 and the anoxic pool 3 respectively through the water inlet pump 10 ; The first degassing tank 5 is communicated with anoxic tank 3, and anoxic tank 3 is communicated with anaerobic tank 2, and anaerobic tank 2 is communicated with deep well aeration tank 4 by inlet pump 10, and deep well aeration tank 4 is conne...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 2 Describe this embodiment, the method for the enhanced denitrification and dephosphorization of waste water in this embodiment is carried out according to the following steps:

[0031] 1. Domesticated activated sludge in the deep well aeration tank 4;

[0032] Two, pass the activated sludge and sewage domesticated in the deep well aeration tank 4 to the anaerobic tank 2, the anoxic tank 3, the first degassing tank 5, the second degassing tank 6, the secondary sedimentation tank 7; then Turn on the water inlet pump 10, the aeration device 4-1 and the agitator 9, and the sewage in the water storage tank 1 enters the anaerobic pool 2 and the anoxic pool 3 respectively, and the water inflow of the anaerobic pool 2 is the total water output of the water storage tank 1 25% to 75% of the water in the anoxic pool 3 is 75% to 25% of the total water output of the water storage tank 1; the sewage in the anoxic pool 3 is sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com