A kind of composite modifier of starch/polyvinyl alcohol composite material

A technology of polyvinyl alcohol and composite materials, which is applied in the field of plasticizer-surfactant composite modifiers, can solve the restrictions on the promotion and use of starch/polyvinyl alcohol composite materials, the limited plasticization efficiency of starch and polyvinyl alcohol, and the composite Poor film water resistance and other problems, to achieve the effect of reducing the content of metal ions and halogen ions, significant plasticizing effect, and water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

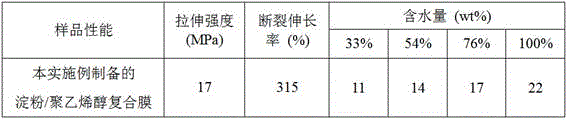

[0022] Dissolve 15 parts of anhydrous calcium chloride, 0.5 parts of Span-85, 50 parts of starch and 50 parts of polyvinyl alcohol (1799 series) in water, heat and dissolve in a 90°C water bath to prepare a 5 wt% film-forming solution. The above film-forming solution was dried in a vacuum oven at 50 °C for 24 h to obtain a starch / polyvinyl alcohol composite film. The relevant performance data are shown in Table 1.

[0023] The performance of the starch / polyvinyl alcohol film prepared in the embodiment 1 of table 1

[0024]

Embodiment 2

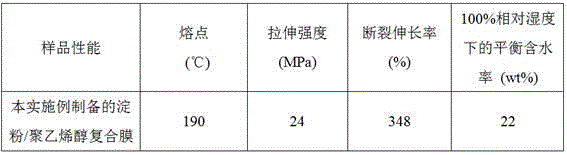

[0026] 30 parts of magnesium chloride hexahydrate, 0.2 parts of Tween-20, 30 parts of starch and 70 parts of polyvinyl alcohol (2099 series) were dissolved in water, heated and dissolved in a 90°C water bath to prepare a 5 wt% film-forming solution. The above film-forming solution was dried in a vacuum oven at 60 °C for 24 h to obtain a starch / polyvinyl alcohol composite film. The relevant performance data are shown in Table 2.

[0027] The performance of the starch / polyvinyl alcohol film prepared in the embodiment 2 of table 2

[0028]

Embodiment 3

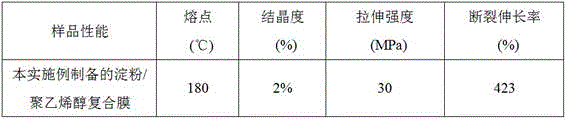

[0030] 30 parts of aluminum chloride hexahydrate, 5 parts of glyceryl monostearate, 60 parts of starch and 40 parts of polyvinyl alcohol (1799 series) were heated and dissolved in a 90°C water bath to prepare a 10 wt% film-forming solution. The above film-forming solution was dried in a vacuum oven at 60 °C for 24 h to obtain a starch / polyvinyl alcohol composite film. The relevant performance data are shown in Table 3.

[0031] The performance of the starch / polyvinyl alcohol film prepared in the embodiment 3 of table 3

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com