Method for producing rocket kerosene by coal tar

A coal tar and rocket technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., to achieve the effect of low raw material, excellent performance and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

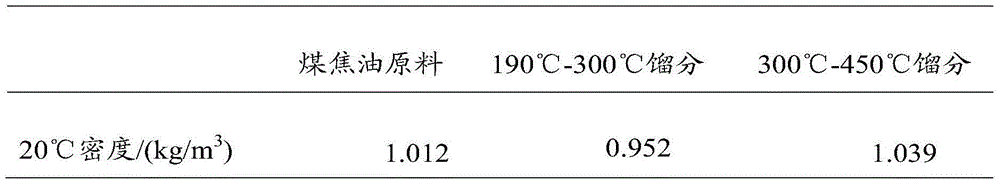

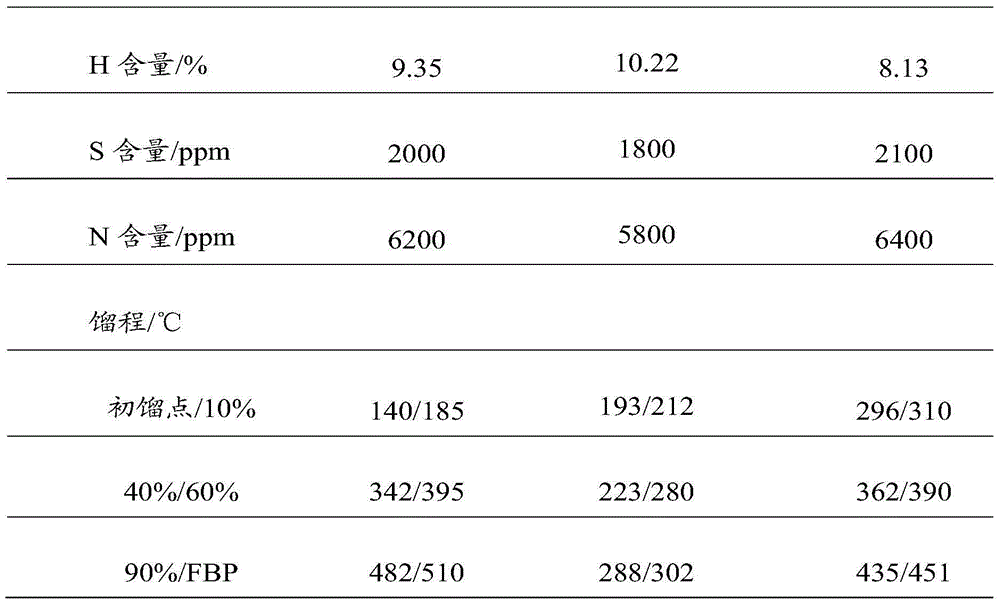

Embodiment 1

[0054] Step (1): The hydrocracking catalyst Z-863 is broken into small particles with a particle diameter of 50 μm, mixed with the 300° C.-450° C. fraction of coal tar, and the addition amount of the catalyst is 1.5% (weight). The 300°C-450°C fraction mixed with the catalyst is pumped into the fluidized bed reactor with a high-pressure pump, and mixed with hydrogen before the raw material enters the reactor. Raw material coal tar and hydrogen at a reaction temperature of 480°C, a pressure of 8MPa, and a liquid hourly space velocity of 0.5h -1 , Hydrogen oil volume ratio under the condition of 2000 to react. After gas-liquid and liquid-solid separation of the hydrocracking reaction product, hydrocracking product oil is obtained, and its properties are shown in Table 3.

[0055] Step (2): Mix the hydrocracking product oil obtained in step (1) with the 190°C-300°C fraction of coal tar at a ratio of 2:1, and use it as a fixed-bed hydrorefining reaction feed. The self-made cataly...

Embodiment 2

[0062] Step (1): Same as step (1) in Example 1.

[0063] Step (2): same as step (2) of Example 1, wherein the change is the loading volume of the catalyst, the purpose is to reduce the fluid linear velocity to investigate the reaction effect under different linear velocity. The self-made catalyst 1 was broken into 40-60 mesh catalyst particles, which were packed in a fixed-bed hydrogenation reactor with a loading volume of 70 mL. Reaction condition is the same as embodiment 1 step (2). After calculation, the linear velocity of oil flow under this condition is 1mm / s, and the actual linear velocity of hydrogen under the reaction pressure is 2.6mm / s.

[0064] Step (3): Fractional distillation of the hydrorefined product oil in step (2) to obtain fractions at 190-280° C., the properties of which are shown in Table 4.

[0065] As shown in Table 4, the density of the 190-280°C distillate of hydrorefined product oil is 0.832kg / m 3 , the volumetric calorific value is 35.17MJ / L, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume calorific value | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com