Preparation method of boron-containing silicon carbide fiber

A technology of silicon carbide fiber and polycarbosilane, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems that the preparation of boron-containing silicon carbide fiber cannot be replicated or cannot be completely replicated, and achieves non-toxic waste and melt spinning Good performance, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

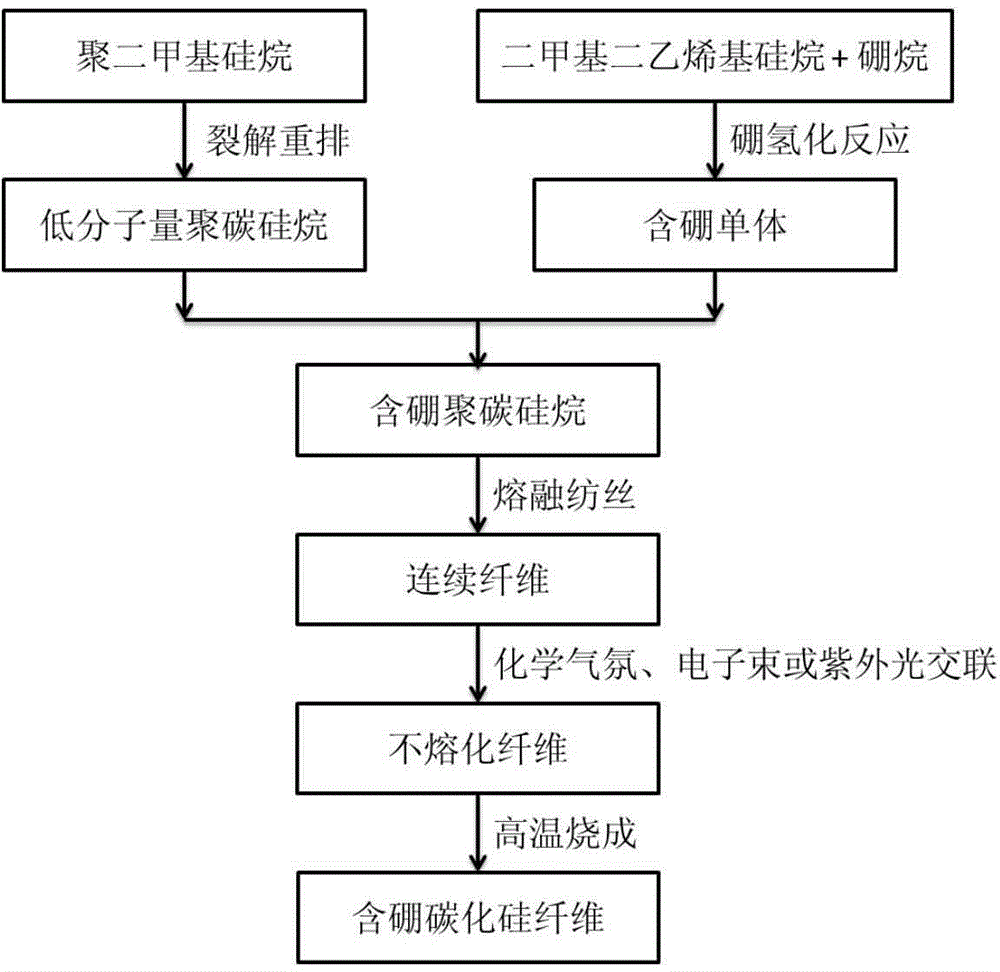

[0029] The boron-containing SiC fiber prepared by boron-containing polycarbosilane in the present invention mainly lies in the synthesis of boron-containing polycarbosilane, and its synthesis method includes:

[0030] (1) The low molecular weight polycarbosilane LPCS has a number average molecular weight of 500-1200 and a molecular weight distribution coefficient of 1.0-1.5.

[0031] (2) Mix dimethyldivinylsilane and borane at a ratio of 3 to 1:1 under nitrogen protection at room temperature, heat to 60°C for 24 hours, then heat up to 120°C for distillation to remove unreacted raw materials, drop The boron-containing monomer can be obtained at room temperature as an oily transparent liquid.

[0032] (3) Under the protection of nitrogen, the above LPCS is dissolved in xylene, and a boron-containing monomer is added, and the weight ratio of the boron-containing monomer to the LPCS is 5% to 20%. Then raise the temperature to 120°C and keep it for 12-24h, then raise the temperatu...

Embodiment 1

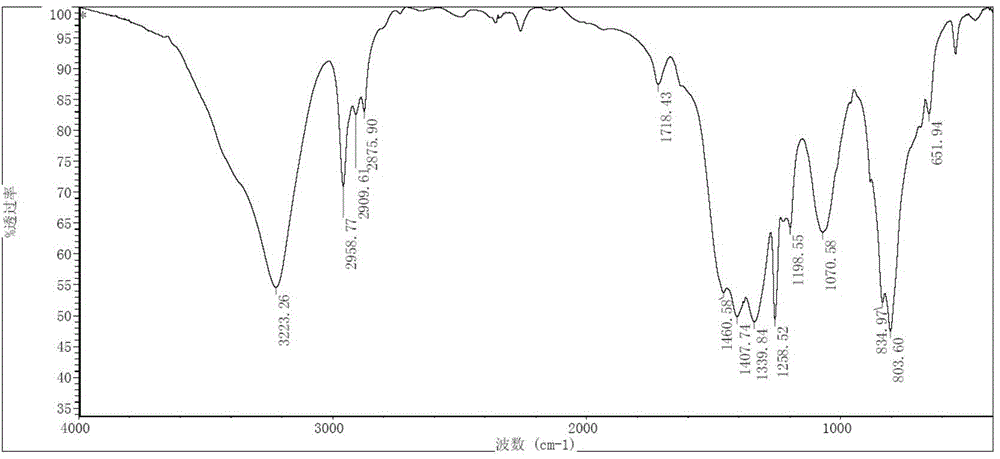

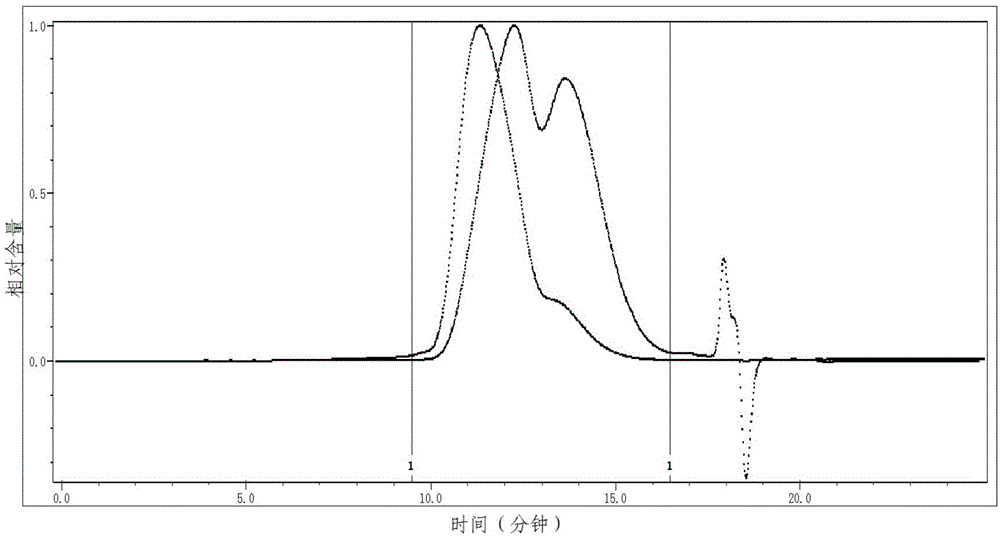

[0035]The low molecular weight polycarbosilane LPCS, with a number average molecular weight of 500 and a molecular weight distribution coefficient of 1.0, was dissolved in an equal weight of xylene. (2) Mix dimethyldivinylsilane and borane dimethyl sulfide at a ratio of 1:1 under nitrogen protection at room temperature, heat to 60°C for 24 hours, then heat up to 120°C for distillation to remove unreacted raw materials , the boron-containing monomer can be obtained at room temperature, figure 1 is the infrared spectrum of the boron-containing monomer; (3) under the protection of nitrogen, add the boron-containing monomer to the xylene solution of LPCS, and the weight ratio of the boron-containing monomer to LPCS is 20:100. Then raise the temperature to 120°C and keep it for 24h, then raise the temperature to 250°C and keep it for 6h, then raise the temperature to 350°C and keep it for 4h, then distill at 20Pa for 2h, cool to room temperature to get boron-containing polycarbosil...

Embodiment 2

[0038] The low molecular weight polycarbosilane LPCS, with a number average molecular weight of 960 and a molecular weight distribution coefficient of 1.3, was dissolved in an equal weight of xylene. (2) Mix dimethyldivinylsilane and borane dimethyl sulfide at a ratio of 2:1 under nitrogen protection at room temperature, heat to 75°C for 12 hours, then heat up to 150°C for distillation to remove unreacted raw materials , the boron-containing monomer can be obtained when the temperature is lowered to room temperature. (3) Under the protection of nitrogen, add the boron-containing monomer to the xylene solution of the above LPCS, and the weight ratio of the boron-containing monomer to LPCS is 10:100. Then raise the temperature to 150°C and keep it for 12h, then raise the temperature to 270°C and keep it for 2h, then raise the temperature to 380°C and keep it for 2h, then distill at 100Pa pressure for 1h, cool to room temperature to get boron-containing polycarbosilane.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com