Ultra-thin liquid crystal display and production method thereof

A technology of liquid crystal display and manufacturing method, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of inconvenient lamination and peeling of ultra-thin glass and carrier glass, and cannot be effectively solved, and achieves broad market prospects and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

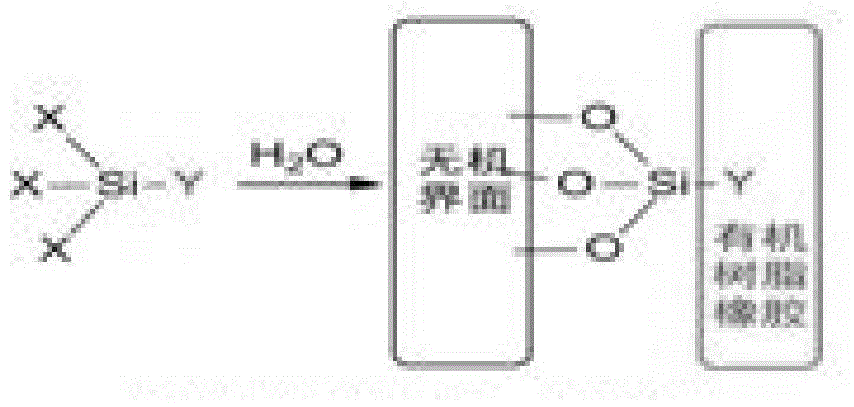

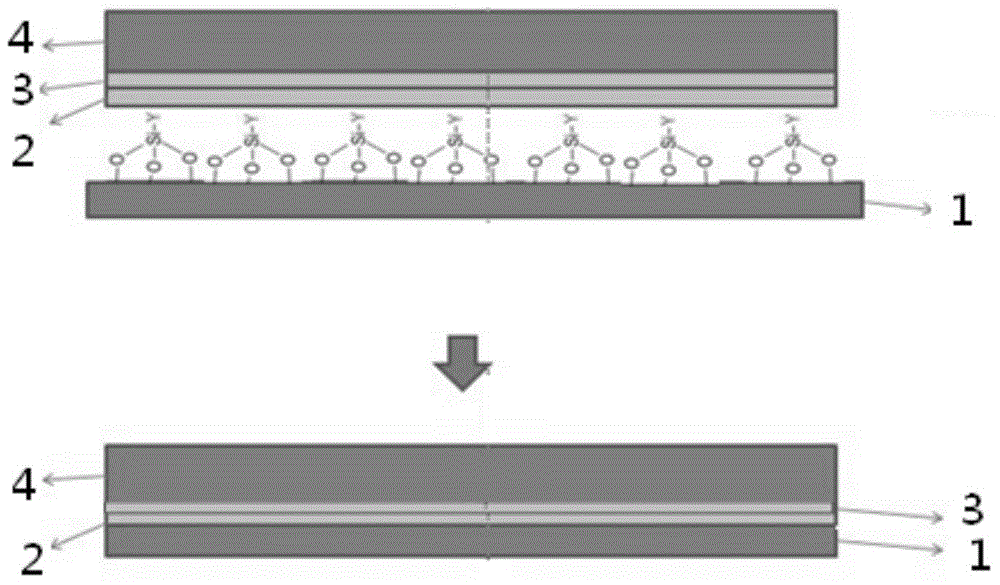

[0064] This embodiment provides a method for manufacturing an ultra-thin liquid crystal display, which specifically includes the following steps (see figure 1 ):

[0065] (1) process the surface of ultra-thin glass with silane coupling agent, method is as follows: the ethanol solution of the silane coupling agent (isobutyltriethoxysilane) 95% of preparation, this solution is put into liquid supply tank and After it is heated to 80-90°C, it is maintained for more than 2 hours, and then it is evenly coated on the surface of ultra-thin glass by spin coating to obtain ultra-thin glass 1 after surface treatment with a silane coupling agent;

[0066] (2) Form an ITO layer 3 on the carrier glass 4, and further form an OC resin layer 2 capable of forming a chemical bond with the silane coupling agent on the ITO layer 3;

[0067] (3) Bond the carrier glass 4 to the surface treated with the silane coupling agent of the ultra-thin glass through the OC resin layer 2: after cleaning the s...

Embodiment 2

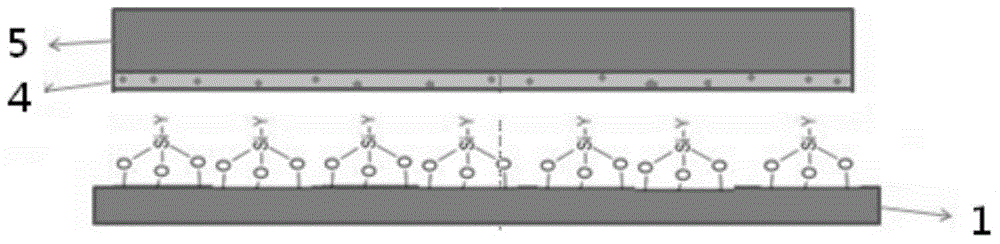

[0069] This embodiment provides a method for manufacturing an ultra-thin liquid crystal display, which specifically includes the following steps (see figure 2 ):

[0070] (1) Treat the surface of the ultra-thin glass with a silane coupling agent, prepare an aqueous solution of the silane coupling agent (isobutyltriethoxysilane), put the solution into the liquid supply tank and heat it to 80-90°C Finally, keep it for more than 2 hours, and then spray it evenly on the surface of ultra-thin glass to obtain ultra-thin glass 1 after surface treatment with silane coupling agent;

[0071] (2) form polyimide layer 5 on carrier glass 4;

[0072] (3) Under heating condition, under the effect of initiator and accelerator, the carrier glass 4 that has formed polyimide layer 5 is pasted on the surface that is processed by silane coupling agent of ultra-thin glass 1, forms self- From top to bottom is a multi-layer composite structure of carrier glass 4, polyimide layer 5 and ultra-thin g...

Embodiment 3

[0074] Compared with embodiment 2, the present embodiment differs only in that in the present embodiment, the formation method of the polyimide layer is as follows:

[0075] (a) After mixing hexafluorodianhydride, norbornene dianhydride, and 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl, they are dissolved in N-methyl pyrrolidone and mixed uniformly to obtain Polyamic acid solution; Wherein, the mass ratio of monomer and solvent is 15 / 85;

[0076] (b) After the polyamic acid solution is chemically imidized, a polyimide having a norbornene group at the end is obtained;

[0077] (c) The polyimide solution obtained by dissolving polyimide in dimethylacetamide is coated on the carrier glass, heated to 180°C for 2 hours, and the solvent is removed to obtain the polyimide solution attached to the surface of the carrier glass. polyimide layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com