Intelligent deep-loosening soil preparation operation quality monitoring system

A quality monitoring and subsoiling technology, applied in the general control system, control/regulation system, program control, etc., can solve the problem of lack of monitoring and alarm functions, inaccurate measurement, and difficulty in ensuring accurate measurement and consistency of tillage depth, etc. problems, to achieve the effect of improving service life and operating efficiency, reducing labor intensity, and facilitating comprehensive evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

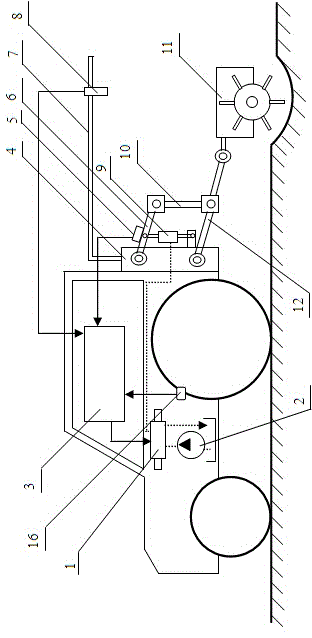

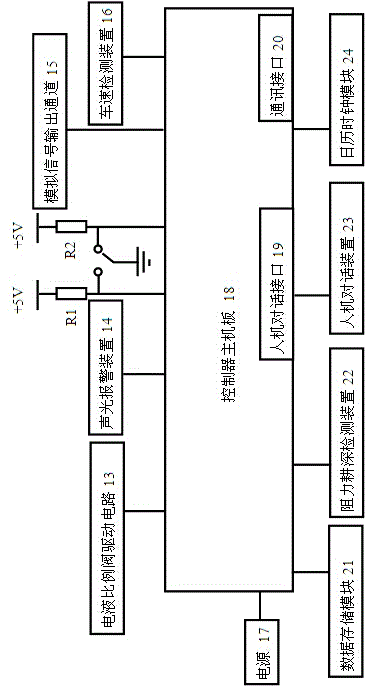

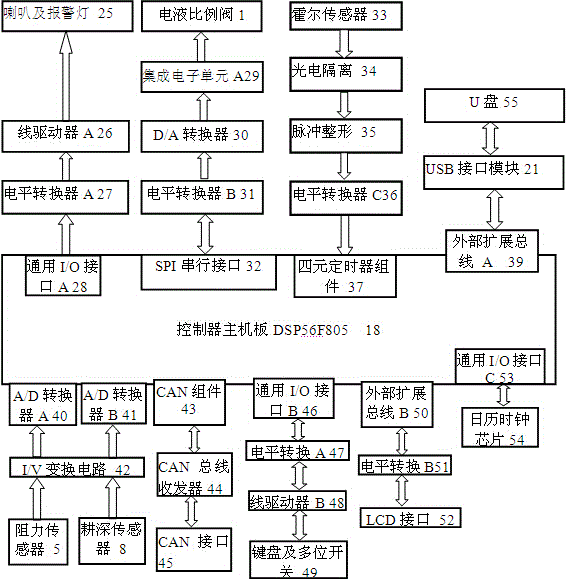

[0026] Such as figure 1 As shown, an intelligent subsoiling soil preparation operation quality monitoring system consists of an electro-hydraulic proportional valve 1, an oil cylinder 2, a controller 3, a fixed seat 4, a resistance sensor 5, an upper pull rod 6, a depth of tillage sensor bracket 7, and a depth of tillage sensor 8 , lifting cylinder 9, lifting arm 10, subsoiling work tool 11 and pull down rod 12 to form. One end of the upper pull rod 6 is connected to the upper end of the lifting arm 10, and the other end is connected to the upper suspension point of the fixed seat 4; one end of the pull rod 12 is connected to the lower end of the lifting arm 10, and the other end is connected to the lower suspension point of the fixed seat 4; Installed on the upper tie rod 6; the tillage depth sensor bracket 7 is an "L-shaped" bracket, one end of whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com