Preparation technology for rail transit vehicle cable

A rail transit vehicle and preparation technology, which is applied in the field of rail transit vehicle cable preparation technology, can solve problems such as difficult product quality control, large manufacturing waste, and complicated process, and achieve sufficient surplus space, long service life, and adaptable range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0036] refer to figure 1 and figure 2, a preparation process of irradiated ethylene-propylene rubber insulated rail transit vehicle cables, the specific steps are as follows:

[0037] Step 1, conductor drawing: first select the basic material for making the conductor, that is, copper rod, and then draw the copper rod into copper wire through a wire drawing machine;

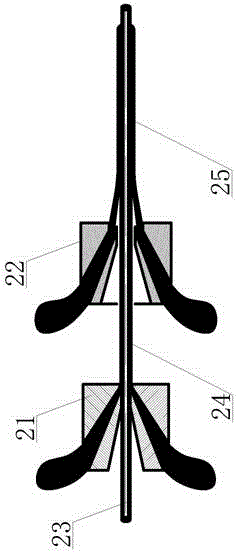

[0038] Step 2, conductor twisting: take some copper wires in step 1 and twist them into cable conductors 23 by a stranding machine;

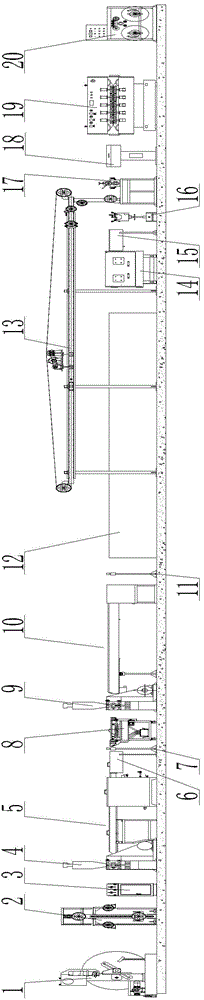

[0039] Step 3, extrusion process: complete through a double-layer extrusion production line, the described double-layer extrusion process is completed through a double-layer extrusion production line, and the described double-layer extrusion production line also includes an active pay-off frame 1, a conductor pre- Heater 2, straightening table 3, insulation layer 24 extruder 4, first constant temperature mobile water tank 5, first hot air drying device 6, first outer diameter mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com