Spherical SiO2-based adsorbent adopting core-shell structure as well as preparation method and application of adsorbent

A technology of spherical silica and shell structure, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as dye pollution, achieve low cost, and solve treatment problems , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

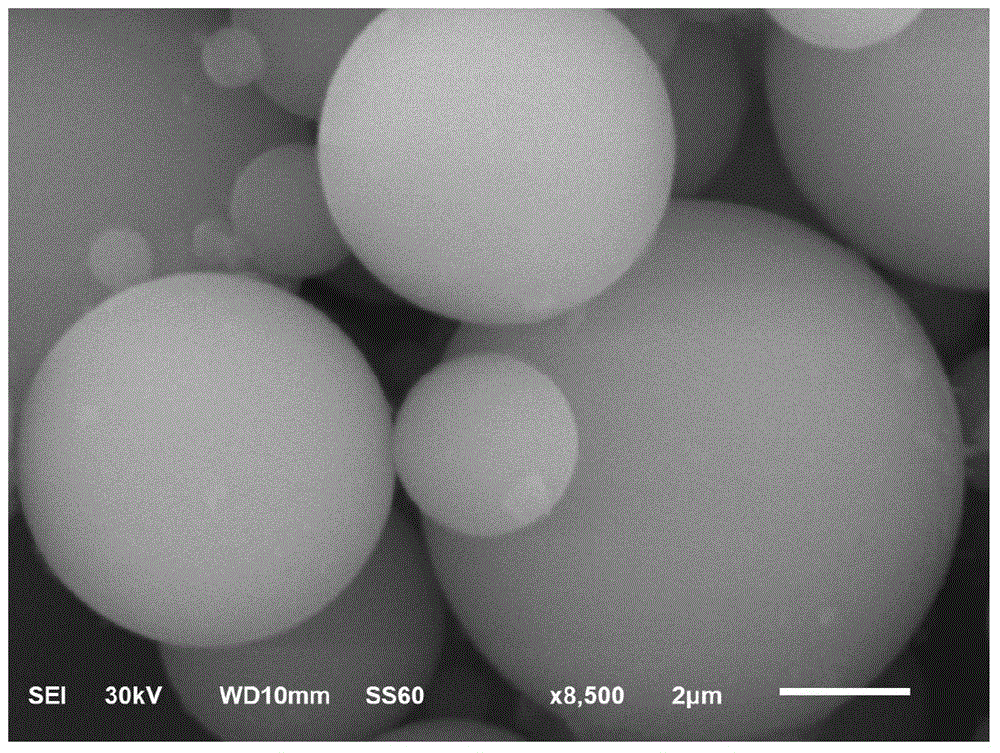

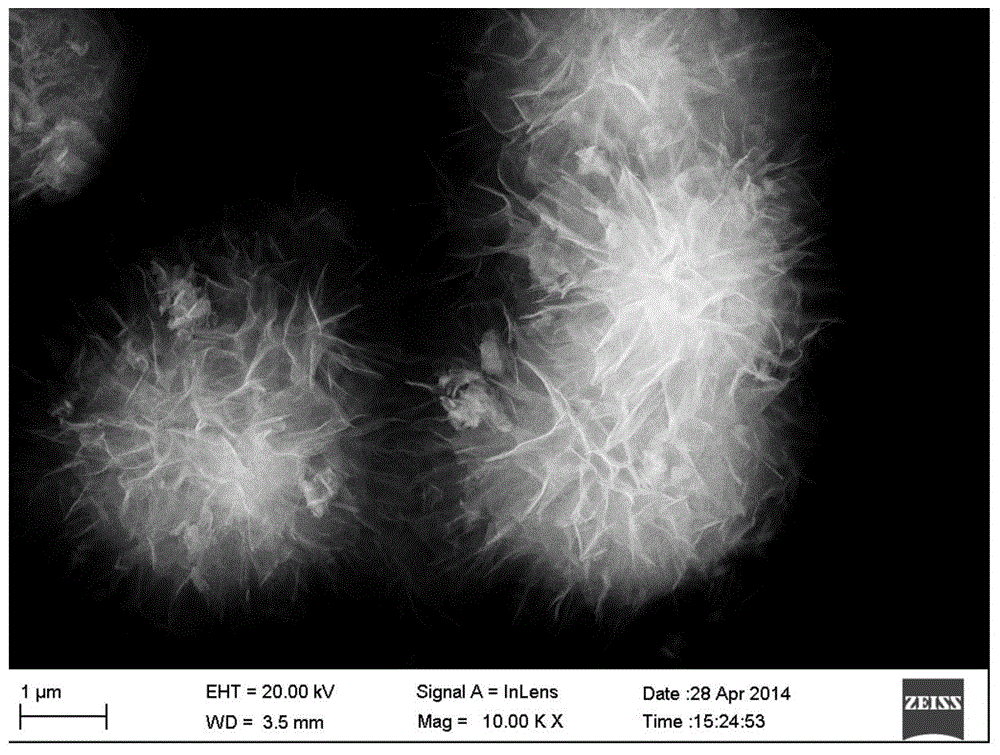

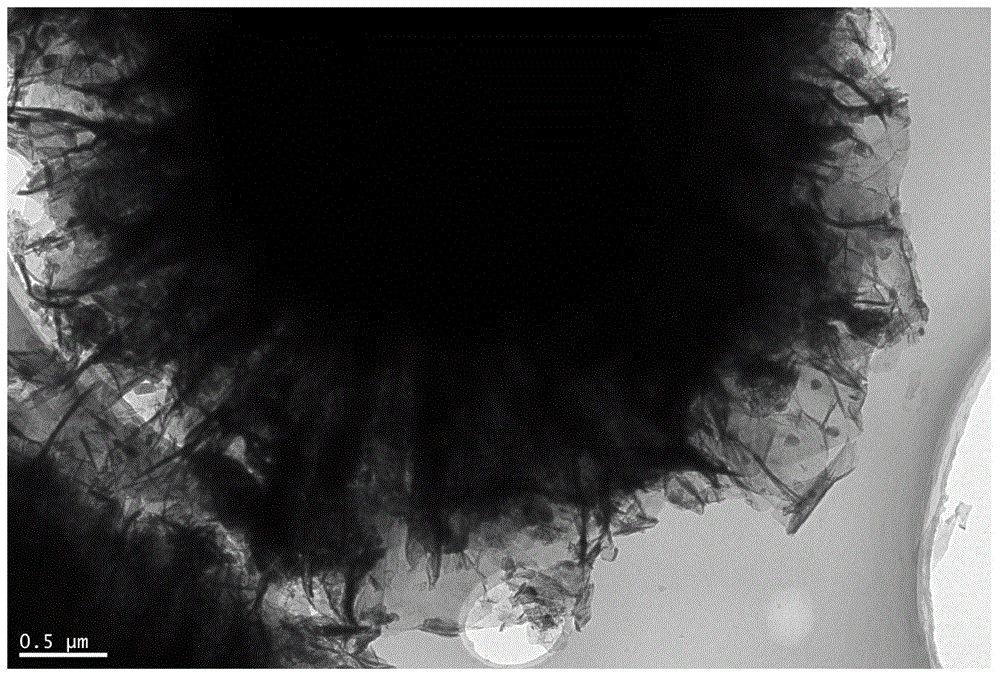

[0024] Weigh 82g MgCl 2 ·6H 2 O was dissolved in 100mL deionized water, and after adding 3g of cetyltrimethylammonium bromide (CTAB), mechanically stirred for ten minutes to obtain the modified MgCl 2 Aqueous solution; at the same time, disperse 5g of silica microspheres in 100mL aqueous solution and add 20g of triethanolamine to obtain modified SiO 2 Dispersions. Under stirring, the modified SiO 2 The dispersion was added to the modified MgCl 2 In aqueous solution, SiO 2 / MgCl 2 Mixture. Subsequently, 50 mL of ammonia water with a concentration of 25 wt% was added dropwise to the SiO 2 / MgCl 2 In the mixed solution, the reaction was stopped after stirring in a water bath at 45° C. for 2 h. Suction filtration and washing, drying at 120°C, and calcining the dried powder in a muffle furnace at 500°C for 3 hours to obtain a spherical silica-based core-shell structure adsorbent in the form of black solid powder.

Embodiment 2

[0026] Weigh 82g MgCl 2 ·6H 2 O was dissolved in 100mL deionized water, and after adding 3g of cetyltrimethylammonium bromide (CTAB), mechanically stirred for ten minutes to obtain the modified MgCl 2 Aqueous solution; at the same time, disperse 10g of silica microspheres in 100mL aqueous solution and add 20g of triethanolamine to obtain modified SiO 2 Dispersions. Under stirring, the modified SiO 2 The dispersion was added to the modified MgCl 2 In aqueous solution, SiO 2 / MgCl 2 Mixture. Subsequently, 50 mL of ammonia water with a concentration of 26 wt% was added dropwise to the SiO 2 / MgCl 2 In the mixed solution, the reaction was stopped after stirring in a water bath at 45° C. for 2 h. Suction filtration and washing, drying at 120°C, and calcining the dried powder in a muffle furnace at 550°C for 3 hours to obtain a spherical silica-based core-shell structure adsorbent in the form of black solid powder.

Embodiment 3

[0028] Weigh 82g MgCl 2 ·6H 2 O was dissolved in 100mL deionized water, and after adding 3g of cetyltrimethylammonium bromide (CTAB), mechanically stirred for ten minutes to obtain the modified MgCl 2 aqueous solution; at the same time, 5 g of silica microspheres were dispersed in 100 mL of aqueous solution and 20 g of triethanolamine was added to obtain modified SiO 2 Dispersions. Under stirring, the modified SiO 2 The dispersion was added to the modified MgCl 2 In aqueous solution, SiO 2 / MgCl 2 Mixture. Subsequently, 50 mL of ammonia water with a concentration of 28 wt% was added dropwise to the SiO 2 / MgCl 2 In the mixed solution, the reaction was stopped after stirring in a water bath at 45° C. for 2 h. Suction filtration and washing, drying at 120°C, and calcining the dried powder in a muffle furnace at 600°C for 3 hours to obtain a spherical silica-based core-shell structure adsorbent in the form of black solid powder.

[0029] After multiple analyzes, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com