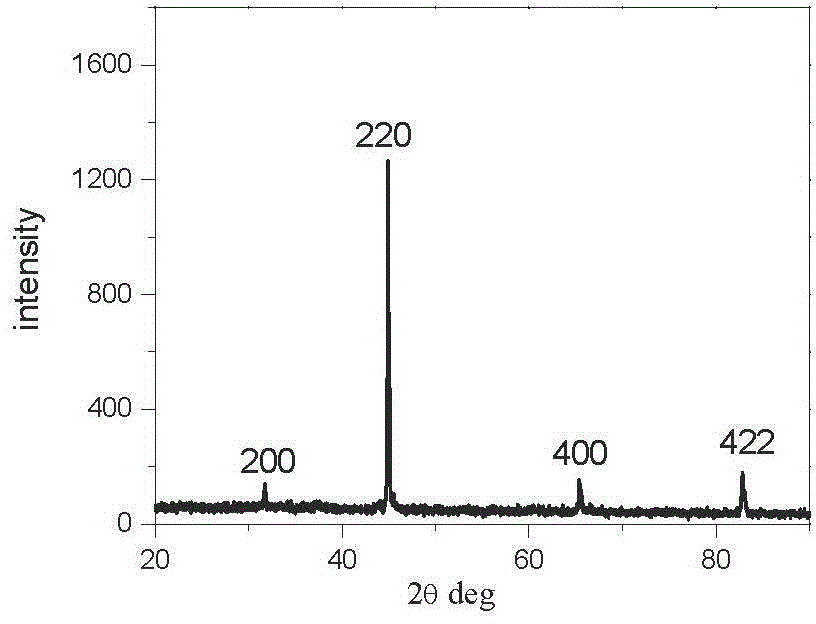

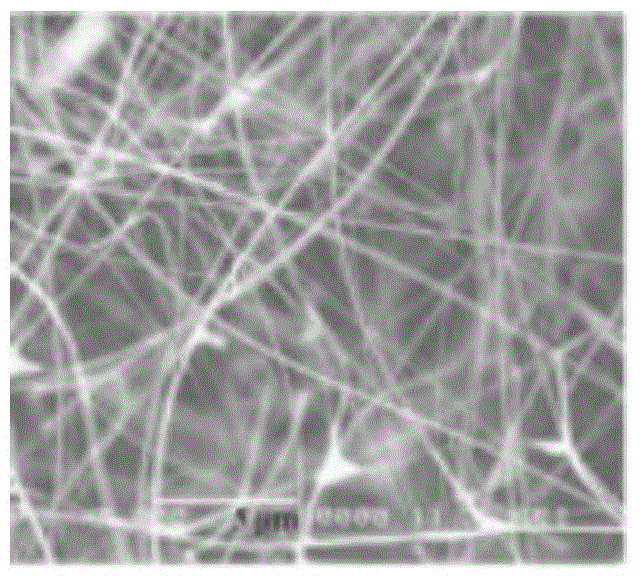

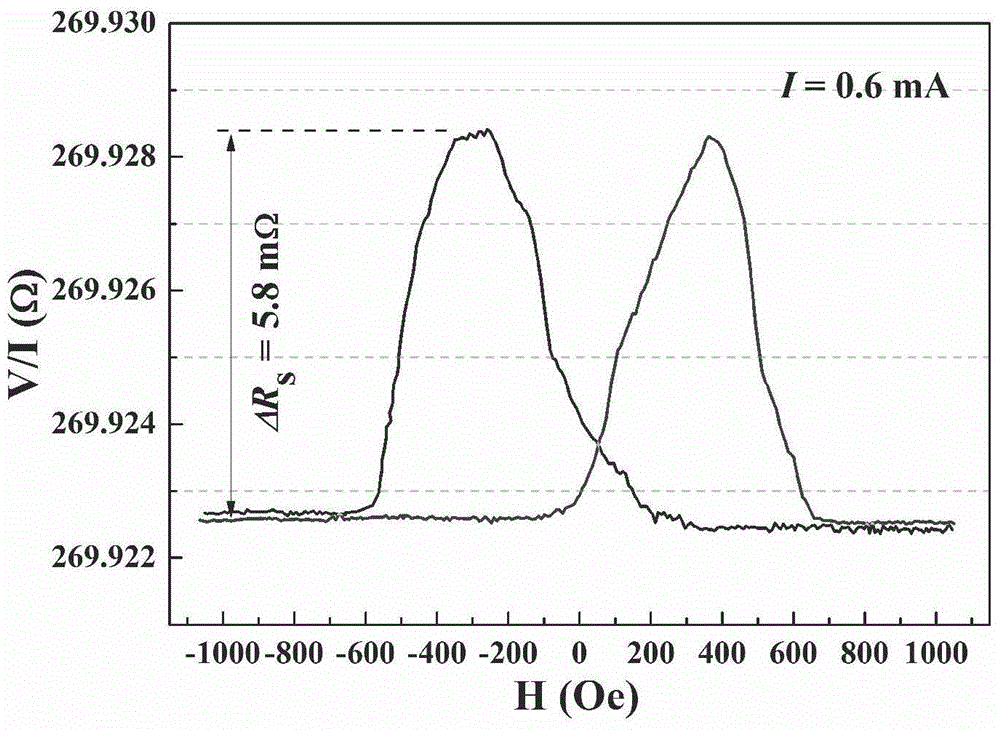

Production method and application of half-metallic Heusler alloy Co2FeAl nanowire

A nanowire and semi-metal technology, which is applied in the preparation of semi-metal Heusler alloy Co2FeAl nanowires, and the field of semi-metal Heusler alloy materials, can solve the problem that the parameter conditions are difficult to control, the process conditions are difficult to control, and the process is cumbersome. and other problems, to achieve the effect of good structure, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A kind of semimetal Hasler alloy Co of the present embodiment 2 The preparation method of FeAl nanowire, its concrete steps are as follows:

[0034] (1) Weigh 2.855g (12mmol) of CoCl with a purity of 99% 2 ·6H 2 O, 2.424g (6mmol) of 99% Fe(NO 3 ) 3 9H 2 O, 1.999g (3mmol) Al with a purity of 98% 2 (SO 4 ) 3 18H 2 O, three kinds of raw materials are reserved;

[0035] (2) Dissolve the weighed cobalt chloride, ferric nitrate and aluminum sulfate raw materials described in step (1) in 900ml deionized water to make a uniform and transparent mixed solution, and keep stirring with a glass rod;

[0036] (3) Weigh 2.4g of NaOH solid particles and dissolve them in 100ml of deionized water to prepare a NaOH solution, then add the NaOH solution dropwise to the continuously stirring uniform transparent mixed solution described in step (2), as With the addition of NaOH solution, the transparent mixed solution gradually becomes turbid, and turbidity appears in the solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com